Corrugation membrane, spiral membrane component thereof and filtering method

A corrugated membrane, roll membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of thick frame structure and low packing density of the assembly, and achieve enhanced pollution resistance and material saving. Cost and effect of large runner gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

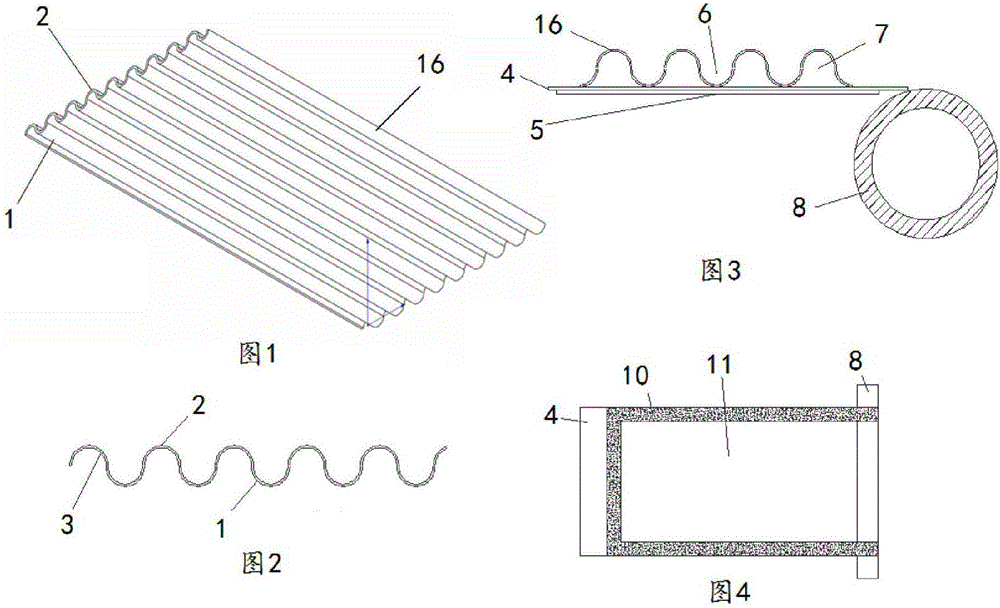

[0034] Embodiment 1: a kind of corrugated membrane and roll-type membrane element thereof, as shown in Fig. 1, Fig. 2, Fig. 3, the non-woven support layer 1 of corrugated membrane 16 connects corrugated membrane membrane surface 2, and the side of corrugated membrane 16 has The corrugation radius is 3, the lower part of the corrugated film 16 is connected to the permeable water channel cloth 4, the lower part of the permeable water channel cloth 4 is connected to the flat film 5 (the existing flat film on the market), and the upper part of the corrugated film 16 (viewed from the side) is corrugated The trough is the water inlet channel 6 (also called the concentrated water channel, the gap between the flat film and the corrugated film after crimping), through which the water channel cloth 4 and the flat film 5 structure and the corrugated film 16 form a corrugated cavity For the permeable water channel 7,

[0035] As shown in Figure 4, the permeable water channel cloth 4 is co...

Embodiment 2

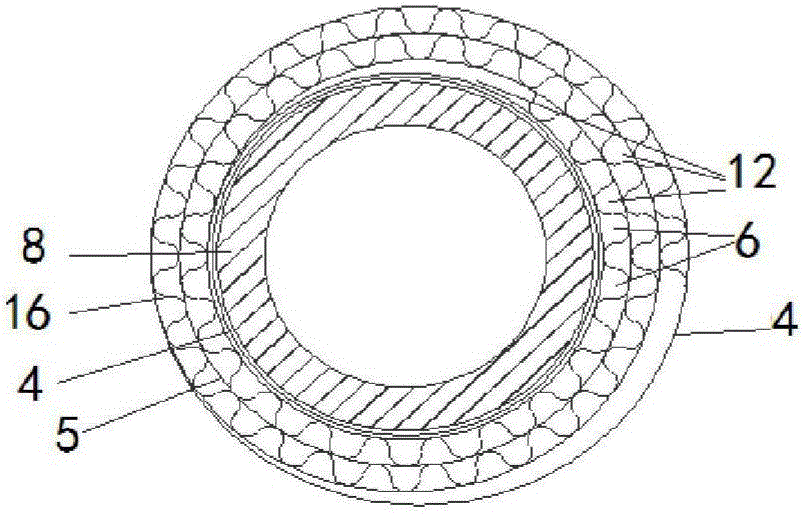

[0038] Embodiment 2: as shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Figure 5 As shown, a corrugated membrane and its roll-type membrane element include a corrugated membrane 16, a non-woven support layer 1, a corrugated flat membrane surface 2, a corrugated radius 3, a water flow channel cloth 4, and a flat membrane 5: existing The flat membrane on the market passes through the water central collection pipe 8, the water inlet channel 6 (also called the concentrated water flow channel, the gap between the flat membrane and the corrugated membrane after curling), the water passage 7, and the glue line position 10 : The three layers of corrugated membrane, flat membrane and permeable water channel cloth are completely bonded together with adhesive, the bonding position is not permeable, the diaphragm 11 (including the corrugated membrane 16 and the flat membrane 5), the sealing position (glue line) 12,

[0039] Non-woven support layer 1: usually made of PET material, thickness 50-2...

Embodiment 3

[0040] Embodiment 3: as shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Figure 5 Shown, a kind of filtering method of corrugated membrane and roll type membrane element thereof comprises following steps;

[0041] Step 1. Connect the lower part of the corrugated membrane 16 to the permeable water channel cloth 4, and connect the lower part of the permeable water channel cloth 4 to the flat membrane 5;

[0042] Step 2. Connect the permeated water channel cloth 4 to the glue line position 10, and the glue line position 10 wraps the membrane 11 (including the corrugated membrane 16 and the flat membrane 5) and then connects it to the permeated water central collection pipe 8;

[0043] Step 3. Use adhesive to completely bond the three layers of corrugated membrane, flat membrane and permeable water channel cloth together, and the bonding position cannot be permeable;

[0044] Step 4. Wrap the sealing position (glue line) 12 through the water central collection pipe 8, and wrap the throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com