Back washing ultrafiltration water purifier

A technology for backwashing and water purifiers, applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of decreased filtration capacity, secondary pollution, unclean washing, etc., so as to reduce the cost of the filter element and prolong the Filter life, avoid recontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, this embodiment is the manual control backwash ultrafiltration water purifier that adopts ball valve:

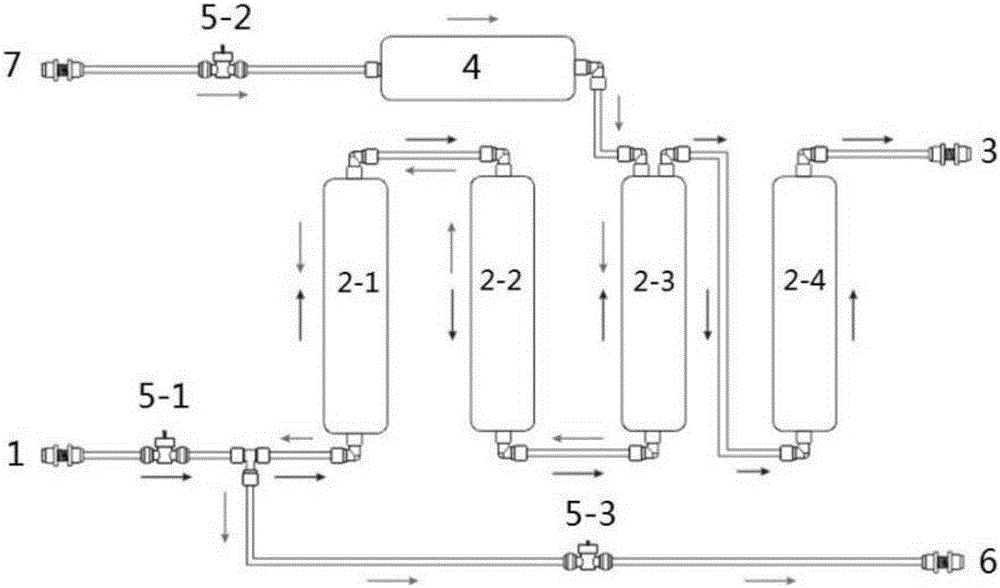

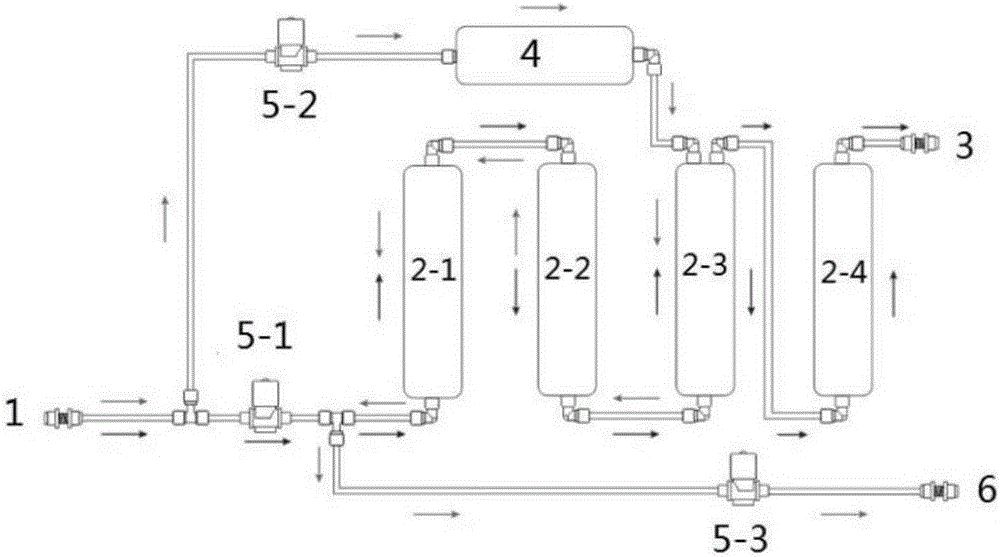

[0025] refer to figure 1 , a backwash ultrafiltration water purifier, comprising a raw water inlet 1, a pre-activated carbon filter element 2-1, a PP cotton filter element 2-2, a water-making ultrafiltration filter element 2-3, and a rear activated carbon filter element arranged in the order of water purification Filter element 2-4, water purification port 3; a first switch 5-1 is set between the pre-activated carbon filter element 2-1 and the raw water inlet 1, which is used to control the pipeline between the raw water inlet and the pre-activated carbon filter element 2-1 , the post activated carbon filter element 2-4 is connected to the water purification port 3; it also includes a flushing ultrafiltration element 4 and a waste water port 6, and the flushing ultrafiltration element 4 is connected to the water-making ultrafiltration element 2-3, and th...

Embodiment 2

[0029] Embodiment 2, this embodiment is the manual control backwashing ultrafiltration water purifier that adopts electromagnetic valve:

[0030] refer to figure 1 , a backwash ultrafiltration water purifier, comprising a raw water inlet 1, a pre-activated carbon filter element 2-1, a PP cotton filter element 2-2, a water-making ultrafiltration filter element 2-3, and a rear activated carbon filter element arranged in the order of water purification Filter element 2-4, water purification port 3; a first switch 5-1 is set between the pre-activated carbon filter element 2-1 and the raw water inlet 1, which is used to control the pipeline between the raw water inlet and the pre-activated carbon filter element 2-1 , the post activated carbon filter element 2-4 is connected to the water purification port 3; it also includes a flushing ultrafiltration element 4 and a waste water port 6, and the flushing ultrafiltration element 4 is connected to the water-making ultrafiltration eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com