Long-chain branched polylactic acid resin and preparation method thereof

A technology of long-chain branching and polylactic acid, applied in the field of polymer materials, can solve the problems of poor blow molding performance, difficult foaming, and low melt strength, and achieve good blow molding performance, good toughness, and high melt strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

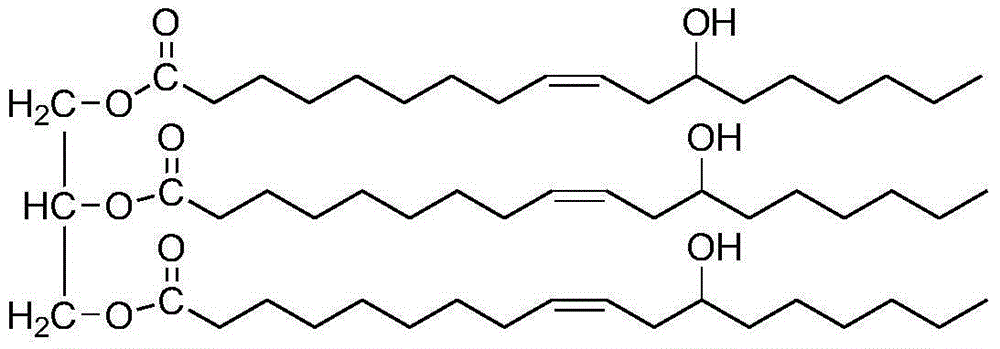

Method used

Image

Examples

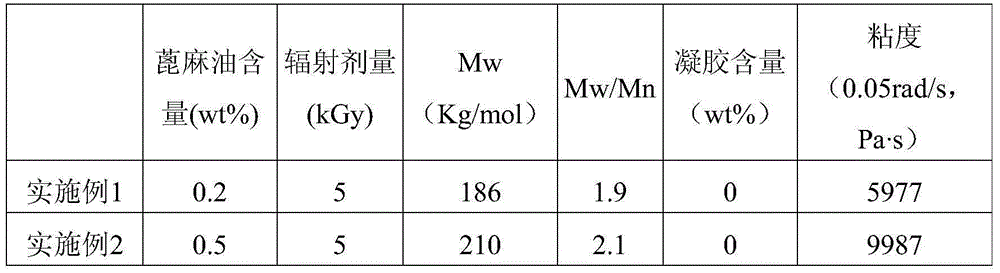

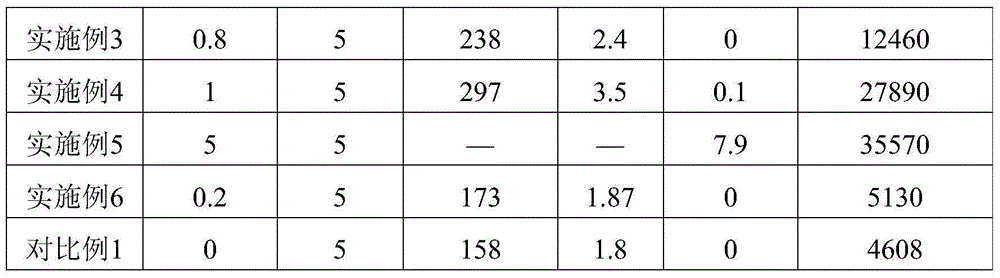

Embodiment 1

[0042] The PLA of 1000g, 2g castor oil and other reagents (0.5g antioxidant 1010, 0.5g antioxidant 168 and 0.5g anti-hydrolysis agent polycarbodiimide) are mixed uniformly to obtain the mixed material; then the mixed The materials were added to a twin-screw extruder for melt blending, the melt blending temperature was 175 degrees Celsius, the screw speed was 45 rpm, and blended for 5 minutes. Then, the strips are drawn and pelletized to obtain the granular mixed resin; the granular mixed resin is subjected to dehydration and drying treatment. The mixed resin is irradiated at normal temperature, the irradiation source is (60) Co-γ rays, the irradiation rate is 2.22kGy / h, and the irradiation dose is 5kGy. After the radiation is finished, the sample is obtained.

Embodiment 2

[0044] The PLA of 1000g, 5g castor oil and other reagents (0.5g antioxidant 1010, 0.5g antioxidant 168 and 0.5g antihydrolysis agent polycarbodiimide) are mixed uniformly to obtain the mixed material; then the mixed The materials were added to a twin-screw extruder for melt blending, the melt blending temperature was 175 degrees Celsius, the screw speed was 45 rpm, and blended for 5 minutes. Then, the strips are drawn and pelletized to obtain the granular mixed resin; the granular mixed resin is subjected to dehydration and drying treatment. The mixed resin is subjected to irradiation treatment, the irradiation source is (60) Co-γ rays, and the irradiation rate is 2.22kGy / h. The irradiation dose is 5kGy. After the radiation is finished, the sample is obtained.

Embodiment 3

[0046] The PLA of 1000g, 8g castor oil and other reagents (0.5g antioxidant 1010, 0.5g antioxidant 168 and 0.5g antihydrolysis agent polycarbodiimide) are mixed homogeneously, obtain the material after mixing; Then after mixing The materials were added to a twin-screw extruder for melt blending, the melt blending temperature was 175 degrees Celsius, the screw speed was 45 rpm, and blended for 5 minutes. Then, the strips are drawn and pelletized to obtain the granular mixed resin; the granular mixed resin is subjected to dehydration and drying treatment. The mixed resin is subjected to irradiation treatment, the irradiation source is (60) Co-γ rays, and the irradiation rate is 2.22kGy / h. The irradiation dose is 5kGy. After the radiation is finished, the sample is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com