A kind of PVC wallpaper that catalyzes degradation of formaldehyde by visible light and preparation method thereof

A catalytic degradation and visible light technology, applied in chemical instruments and methods, special paper, separation methods, etc., can solve the problems of inability to degrade organic pollutants, limited effect of degrading organic pollutants, etc., and achieve the best visible light catalytic activity, low price, The effect of good repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

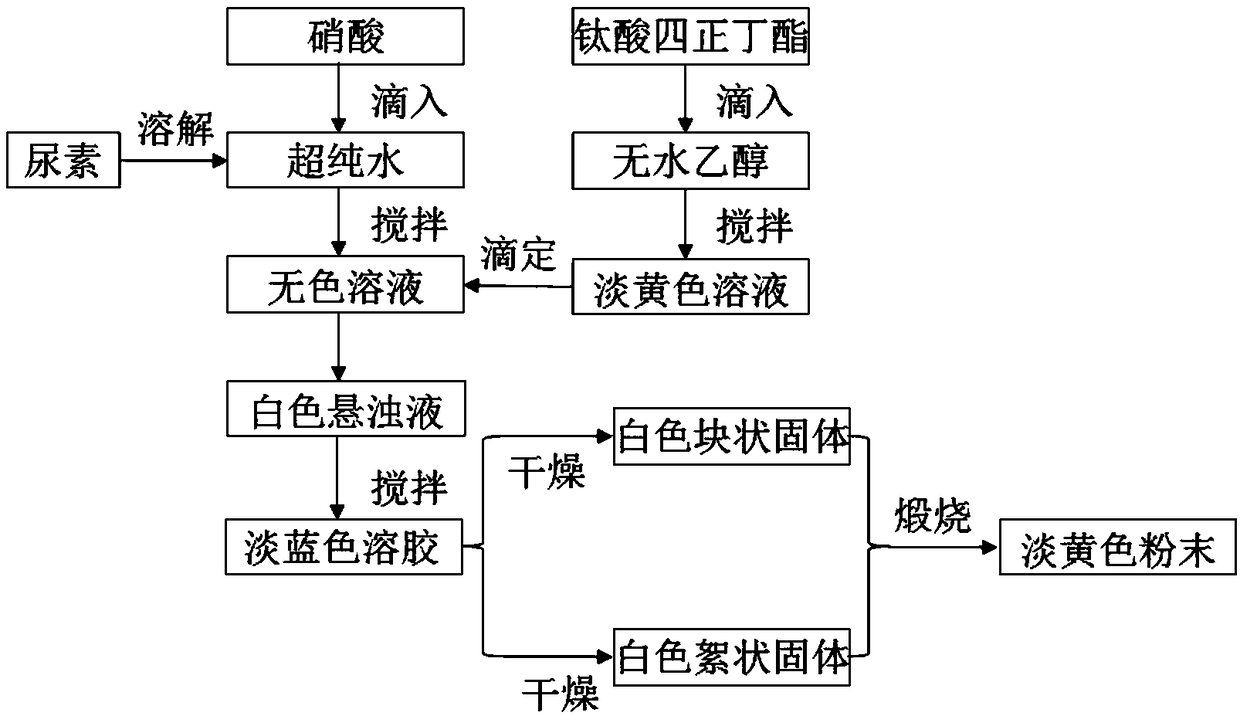

[0050] The invention provides a photocatalyst N-TiO 2 The preparation method, described preparation method comprises the following steps:

[0051] 1) Prepare N-TiO first 2 Sol;

[0052] 2) the N-TiO 2 Put the sol into a freeze dryer and dry it at -55°C to -40°C and 5 to 20Pa for 10 to 14 hours to form white flocculent N-TiO 2 Xerogel;

[0053] 3) the N-TiO 2 The xerogel is calcined at 200-600°C for 2-6 hours to obtain the photocatalyst N-TiO 2 Powder.

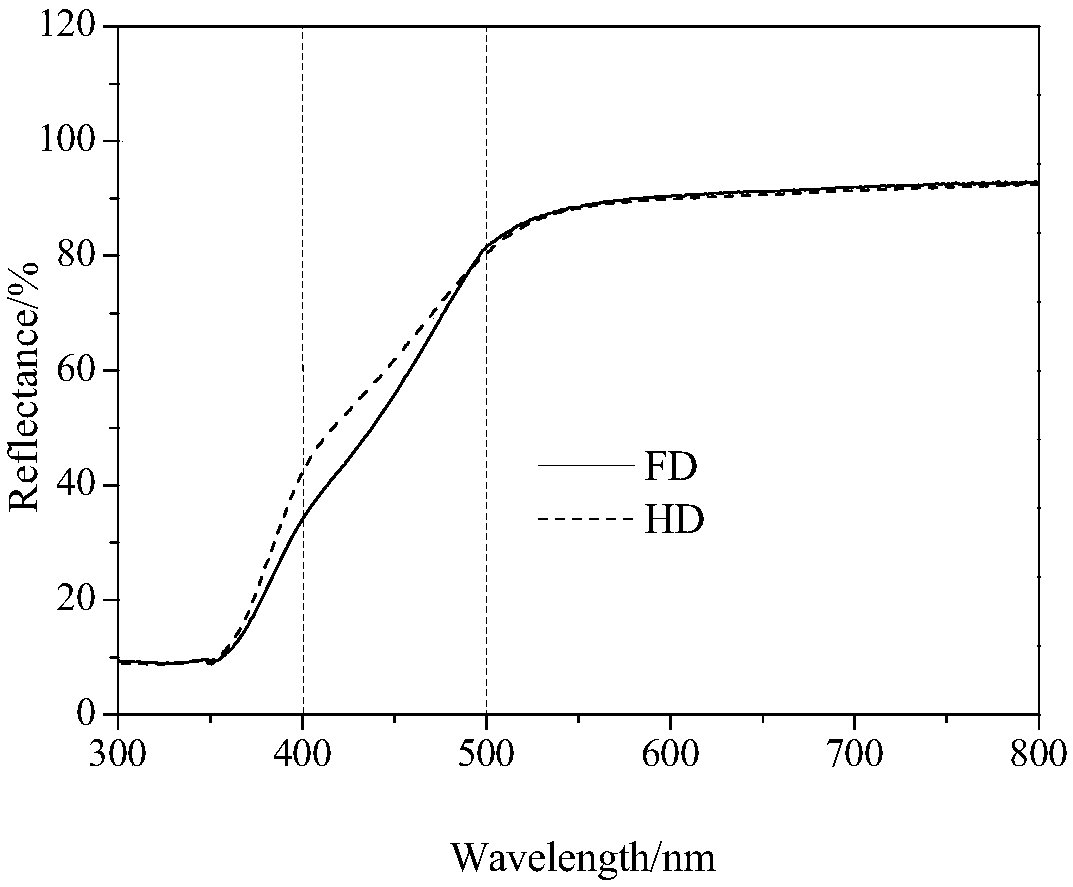

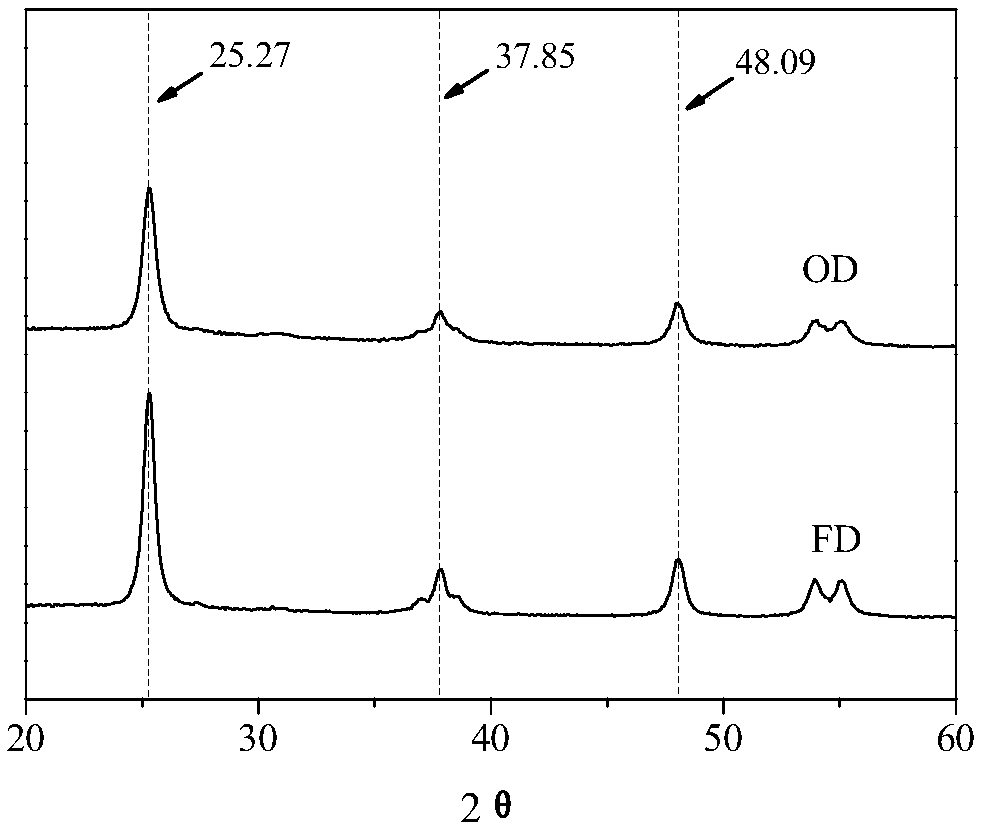

[0054] In the present invention, the N-TiO 2 The sol was freeze-dried, making the prepared photocatalytic N-TiO 2 The light absorption performance of the powder is better, the specific surface area is greatly increased, and the photocatalytic effect is improved. This is because the traditional sol-gel method is used to prepare photocatalyst titanium dioxide (TiO 2 ) process, TiO 2 The sol is generally dried by heat drying (HD) at 60-80°C to form a xerogel, and then the TiO 2 Preparation of photocatalyst TiO by calci...

Embodiment 1

[0072] (1)N-TiO 2 Sol preparation

[0073]Dissolve tetrabutyl titanate in anhydrous ethanol solution first, and mix evenly to obtain a solution A with a concentration of tetrabutyl titanate of 40%;

[0074] Then urea was poured into ultrapure water, and after completely dissolving, solution B with a urea concentration of 250 g / L was obtained. At the same time, nitric acid was added to adjust the pH value of solution B to 2.5.

[0075] Finally, according to the nitrogen / titanium molar ratio of 1:3, slowly titrate solution A into solution B at a rate of 1-2 drops per second, and keep stirring to form a white suspension; After h, light blue-gold N-TiO is formed 2 Sol; wherein, the nitrogen / titanium molar ratio is the molar ratio of the N element moles of urea in solution B to the Ti element molar ratio of tetrabutyl titanate in solution A.

[0076] (2)N-TiO 2 Preparation of Xerogel

[0077] The N-TiO 2 The sol was put into a freeze dryer and dried at -55°C and 20Pa for 14 h...

Embodiment 2

[0081] (1)N-TiO 2 Sol preparation

[0082] Dissolve tetrabutyl titanate in anhydrous ethanol solution first, and mix evenly to obtain a solution A with a concentration of tetrabutyl titanate of 60%;

[0083] Then urea was poured into ultrapure water and completely dissolved to obtain a solution B with a urea concentration of 300 g / L. At the same time, nitric acid was added to adjust the pH of the solution B to 2.0.

[0084] Finally, according to the nitrogen / titanium molar ratio of 1:2, slowly titrate solution A into solution B at a rate of 1-2 drops per second, and keep stirring to form a white suspension; After h, light blue-gold N-TiO is formed 2 Sol; wherein, the nitrogen / titanium molar ratio is the molar ratio of the N element moles of urea in solution B to the Ti element molar ratio of tetrabutyl titanate in solution A.

[0085] (2) N-TiO 2 Preparation of Xerogel

[0086] The N-TiO 2 The sol was put into a freeze dryer and dried at -40°C and 5Pa for 10h to form whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com