Pre-tensioning steel wire and polymer mortar externally-added layer reinforcing device

A reinforcement device and pre-tensioning technology, which is applied in the field of engineering applications, can solve the problems of affecting the beauty of the bridge structure, the inability to provide tension, and the difficulty of tensioning, etc., and achieve the effect of solving effective tensioning problems, good reinforcement effects, and solving aesthetic problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

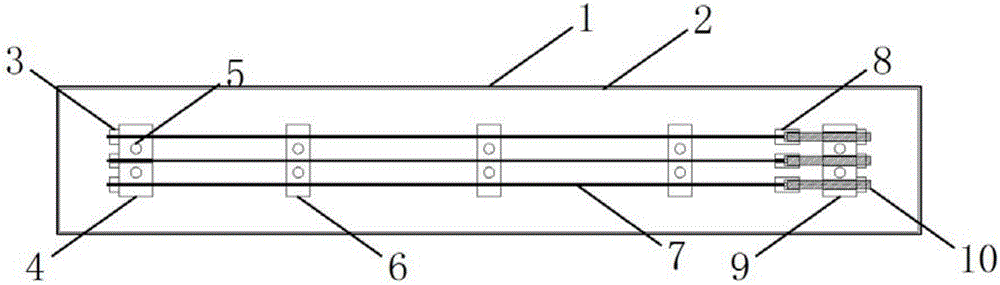

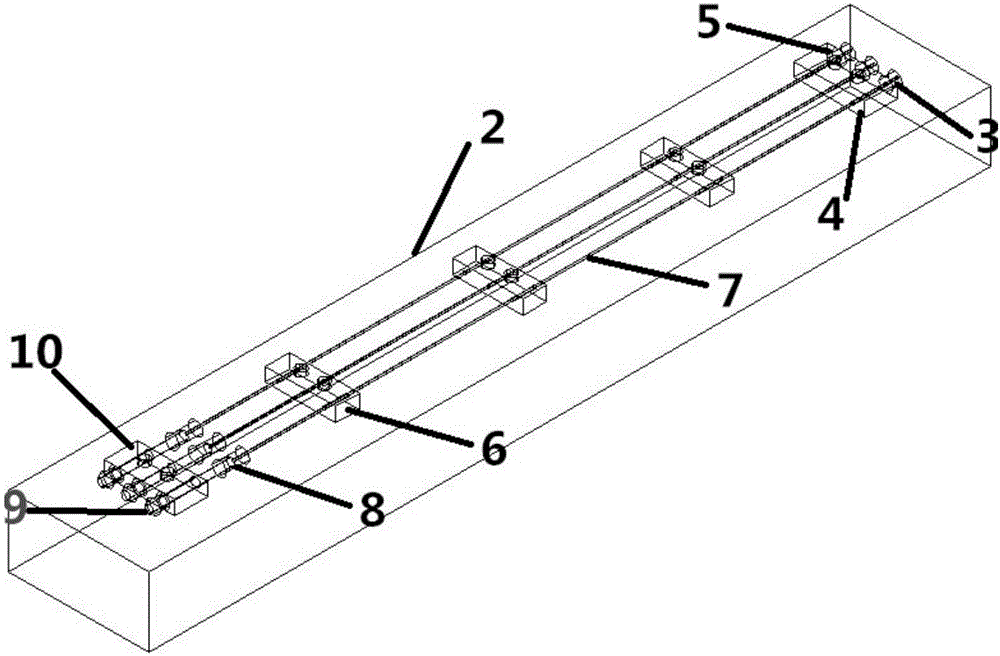

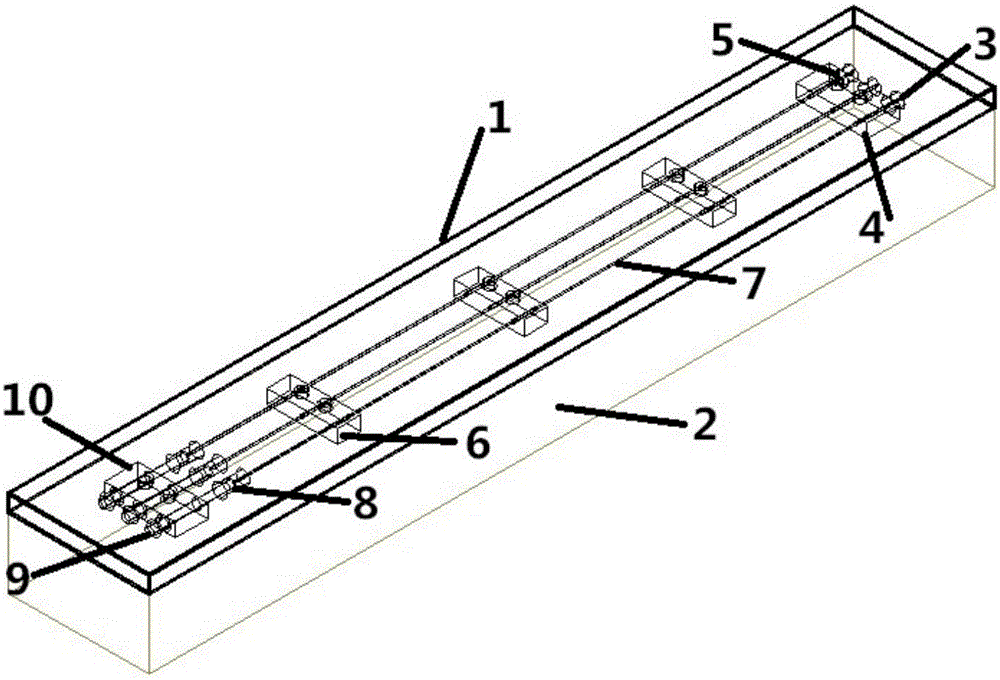

[0027] Such as Figures 1 to 3 As shown, the pre-tensioned steel wire-polymer mortar external layer reinforcement device of the present invention includes a polymer mortar 2, an anchoring end 4, a first extension 6, a high-strength steel wire 7, a second extension 8, and a tension end 9 And threaded steel bar 10; Wherein, anchorage end 4, first extender 6 and tension end 9 are anchored by using nut 5 to anchor on the concrete surface, high-strength steel wire 7 is connected with threaded steel bar 10 by second extender 8, anchored Pier head 3 is used to anchor high-strength steel wire 7 at end 4, and nut 5 is used to anchor threaded steel bar 10 after reaching the design tension. After the surface of the structure is coated with interface agent, polymer mortar 2 is used to coat and concrete beam 1 to form a unified whole.

[0028] In addition, in actual appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com