Foundation pit and side slope envelope enclosure for prestress fabricated special-shaped pile wall

An enclosure structure and prefabricated technology, which is applied in infrastructure engineering, sheet pile walls, excavation, etc., can solve the problems of difficult factory construction of prefabricated standard parts, long construction period of on-site assembly, and difficulty in single-piece transportation. The effect of the project implementation is good, the operation efficiency is high, and the construction quality is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

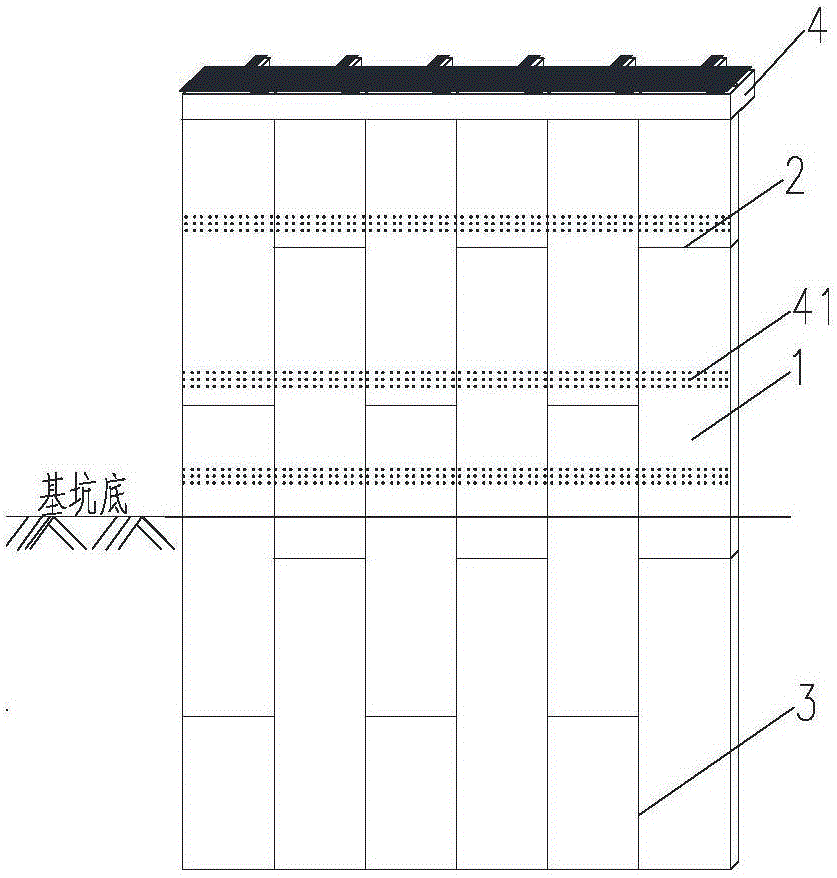

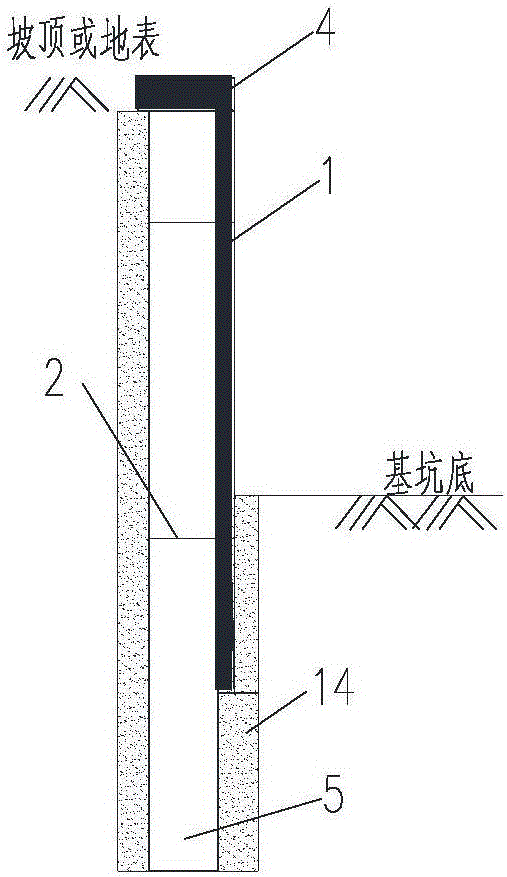

[0059] A foundation pit and slope enclosure structure of a prestressed assembled special-shaped pile wall, which is an enclosure structure aimed at retaining water and soil pressure on vertical slopes or vertically excavated deep foundation pit walls, protecting slope stability and controlling deformation . Based on the stress characteristics and water-stop requirements of the vertical slope enclosure structure, the assembled special-shaped wall developed by the present invention fully exerts the stress performance of T-shaped pile walls, rectangular piles and U-shaped plates.

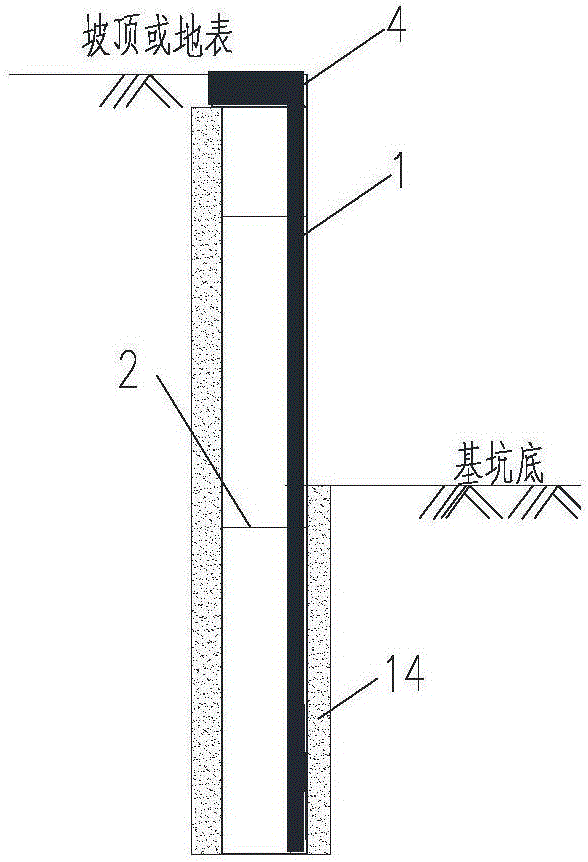

[0060] see figure 1 : The T-shaped reinforced concrete prefabricated standard part 1 is combined with the crown beam 4 to form a special-shaped pile wall structure, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com