Heat preservation and sound isolation wall block with a mutually buckled structure

A technology for thermal insulation and sound insulation and structure connection, which is applied in the structural field of building wall materials and multi-functional lightweight aggregate blocks, can solve problems such as affecting thermal insulation and sound insulation effects, and achieves increased thermal insulation and sound insulation effects, high shear strength, and formula. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

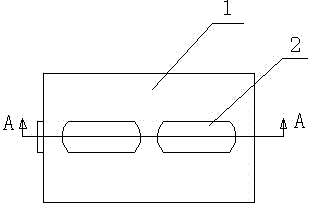

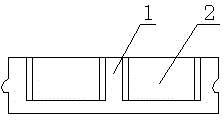

[0020] The thermal insulation and sound insulation wall block with interlocking structure is made of cement, fly ash, river sand, water, cement foaming agent, and foam stabilizer through stirring, foaming, and molding to form a block 1, the block The top surface in the length direction is provided with a row of two thermal insulation grooves 2 with a bottom. The thermal insulation grooves 2 are filled with thermal insulation and sound insulation composite materials 3, and a convex portion 4 is formed on one end surface of the block. A concave portion 5 corresponding to the shape of the above-mentioned convex portion is formed on the end surface. The length of the convex portion along the width direction of the block is equal to the width of the thermal insulation groove, and the external dimension of the concave portion is larger than that of the convex portion. The mass percent of described cement, fly ash, river sand, water, cement foaming agent, foam stabilizer is: cement 40...

Embodiment 2

[0022] The thermal insulation and sound insulation wall block with interlocking structure is made of cement, fly ash, river sand, water, cement foaming agent, and foam stabilizer through stirring, foaming, and molding to form a block 1, the block The top surface in the length direction is provided with a row of two thermal insulation grooves 2 with a bottom. The thermal insulation grooves 2 are filled with thermal insulation and sound insulation composite materials 3, and a convex portion 4 is formed on one end surface of the block. A concave portion 5 corresponding to the shape of the above-mentioned convex portion is formed on the end surface. The length of the convex portion along the width direction of the block is equal to the width of the thermal insulation groove, and the external dimension of the concave portion is larger than that of the convex portion. The mass percent of described cement, fly ash, river sand, water, cement foaming agent, foam stabilizer is: cement 40...

Embodiment 3

[0024] The thermal insulation and sound insulation wall block with interlocking structure is made of cement, fly ash, river sand, water, cement foaming agent, and foam stabilizer through stirring, foaming, and molding to form a block 1, the block The top surface in the length direction is provided with a row of two thermal insulation grooves 2 with a bottom. The thermal insulation grooves 2 are filled with thermal insulation and sound insulation composite materials 3, and a convex portion 4 is formed on one end surface of the block. A concave portion 5 corresponding to the shape of the above-mentioned convex portion is formed on the end surface. The length of the convex portion along the width direction of the block is equal to the width of the thermal insulation groove, and the external dimension of the concave portion is larger than that of the convex portion. The mass percent of described cement, fly ash, river sand, water, cement blowing agent, foam stabilizer is: cement 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com