Diamond drill bit

A diamond drill bit and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems that limit the application of diamond drill bits, and achieve the effects of improving rock breaking efficiency, enhancing rock breaking effect, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The following non-limiting examples illustrate the invention.

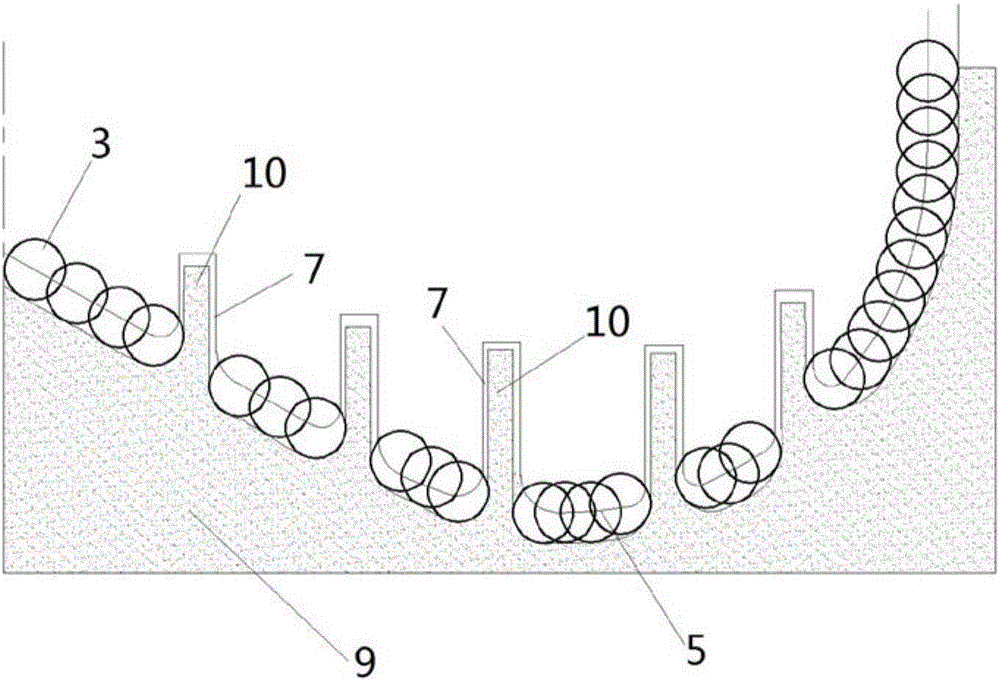

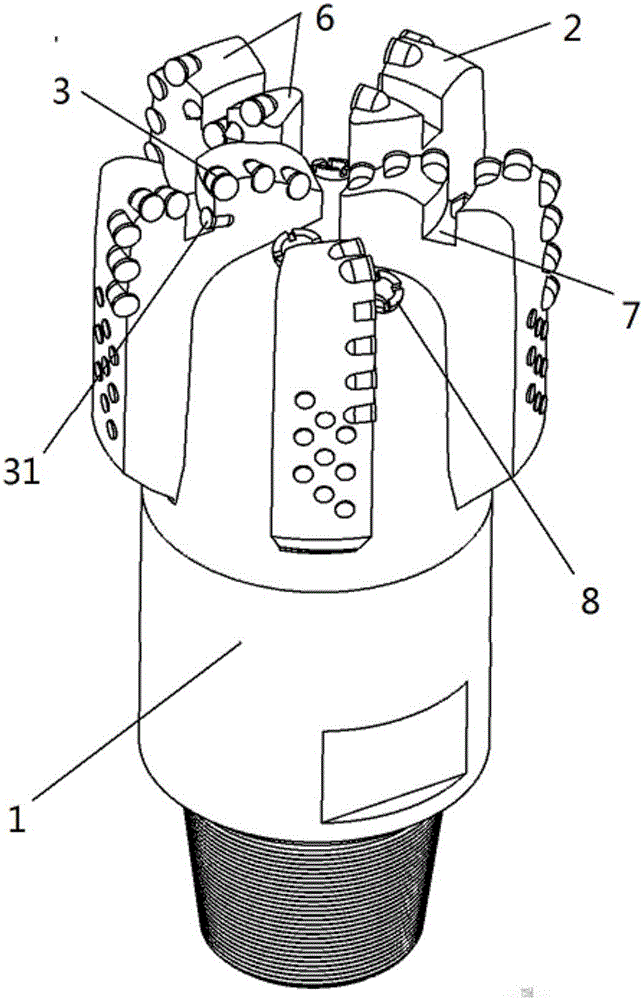

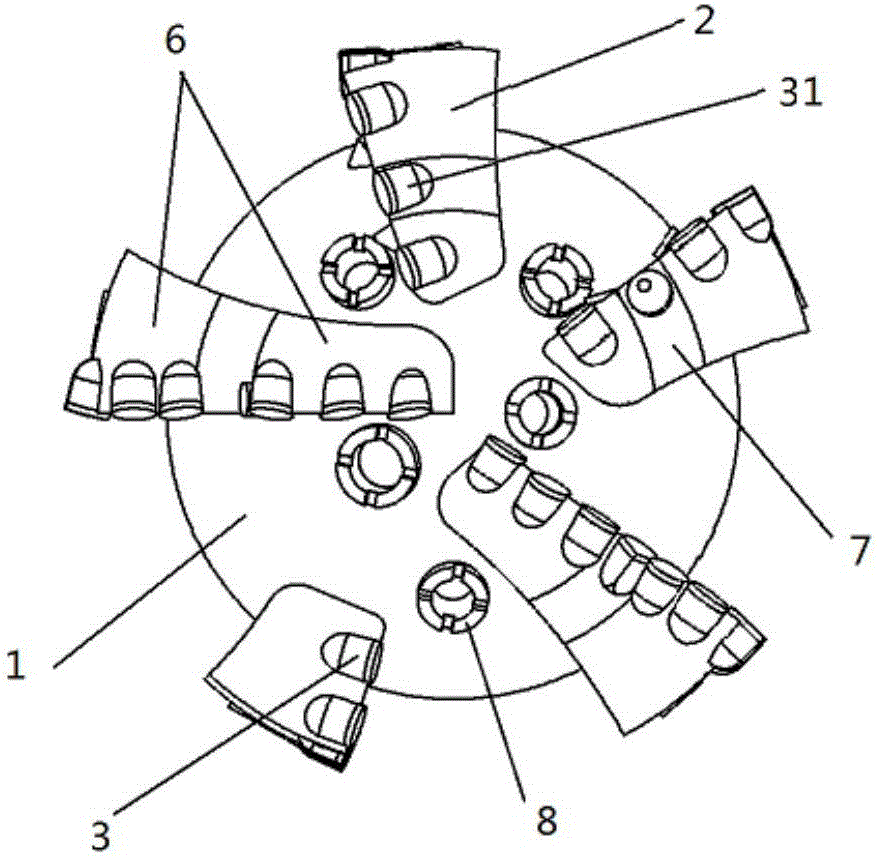

[0068] Such as figure 1 , 2 As shown in , 3, a diamond drill bit includes a drill body 1, and several blades 2 extending from the drill body 1, a cutting element 3 is arranged on the blade 2, and the drill bit has at least one annular space around the center of the drill bit bring( figure 1 In the middle are 5 annular blank zones, figure 2 , 3 Among them is 1 annular blank zone, preferably at least 2 circular blank zones, such as Figure 7-10 There are 2 annular blank belts in the middle), and the blade 2 at the position of the annular blank belt is concaved inwardly, forming a circumferentially penetrating groove 7, and the groove 7 is composed of a side wall and a top. A plurality of annular blank bands on the drill bit form a plurality of grooves 7 on the blade 2, preferably at least 2 grooves, and one of the grooves is located at the center of the drill bit, such as Figure 7 , 8 shown. As pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com