A wind turbine vortex generator

A vortex generator and wind turbine technology, which is applied to wind turbines, wind turbines that are consistent with the wind direction, and wind energy power generation, etc., can solve the problem of aerodynamic performance to be improved, and achieve a firm and reliable structure, strong pertinence, and improved use safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] see Image 6 In this embodiment, the wind turbine is an upwind horizontal axis wind turbine 1 , the blades 2 are connected to the hub 3 , the hub 3 is connected to the nacelle 4 through a rotating shaft, and the nacelle 4 is fixed on the tower 5 .

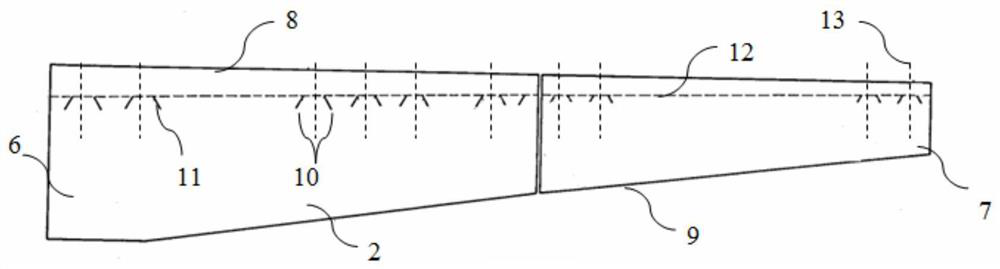

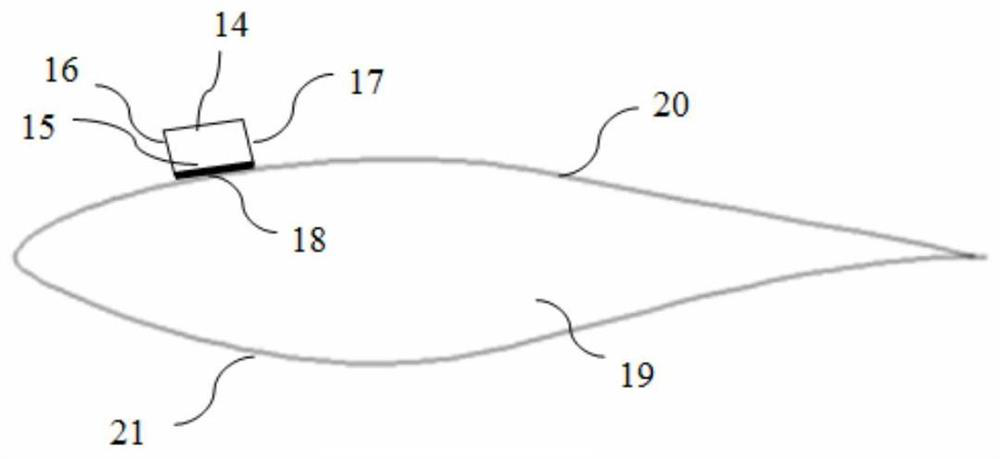

[0038] see figure 1 The blade 2 has a blade root 6, a blade top 7, a blade leading edge 8, a blade trailing edge 9, a cross-sectional airfoil 19, a suction surface 20 and a pressure surface 21, and a vortex generator is arranged on the suction surface 20 of the blade.

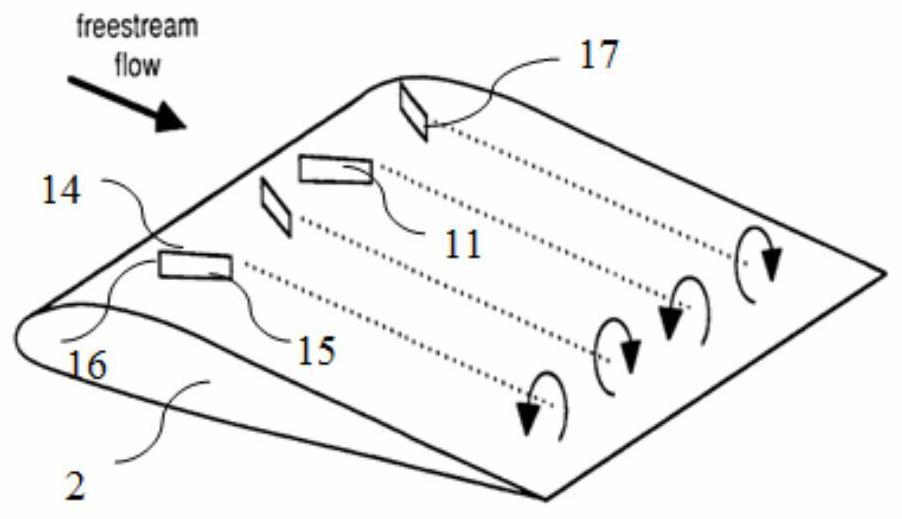

[0039] see figure 1 , figure 2 , image 3 with Figure 4 , the fins forming the vortex generator are set to be rectangular, and every two rectangular fins 11 form a vortex unit 10 in the shape of "eight" with the spanwise positioning line 13 of the vortex generator as axisymmetric; The surface of the suction surface 20 of type 19 and the distance from the leading edge 8 of the blade are 0.1c to 0.2c and the line formed is defined as the chord direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com