Paint slag pyrolysis process and its device

A technology for pyrolysis and paint slag, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve problems such as the inability to effectively realize the harmlessness and recycling of paint slag, pollution, secondary pollution, etc. The effect of detoxification and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

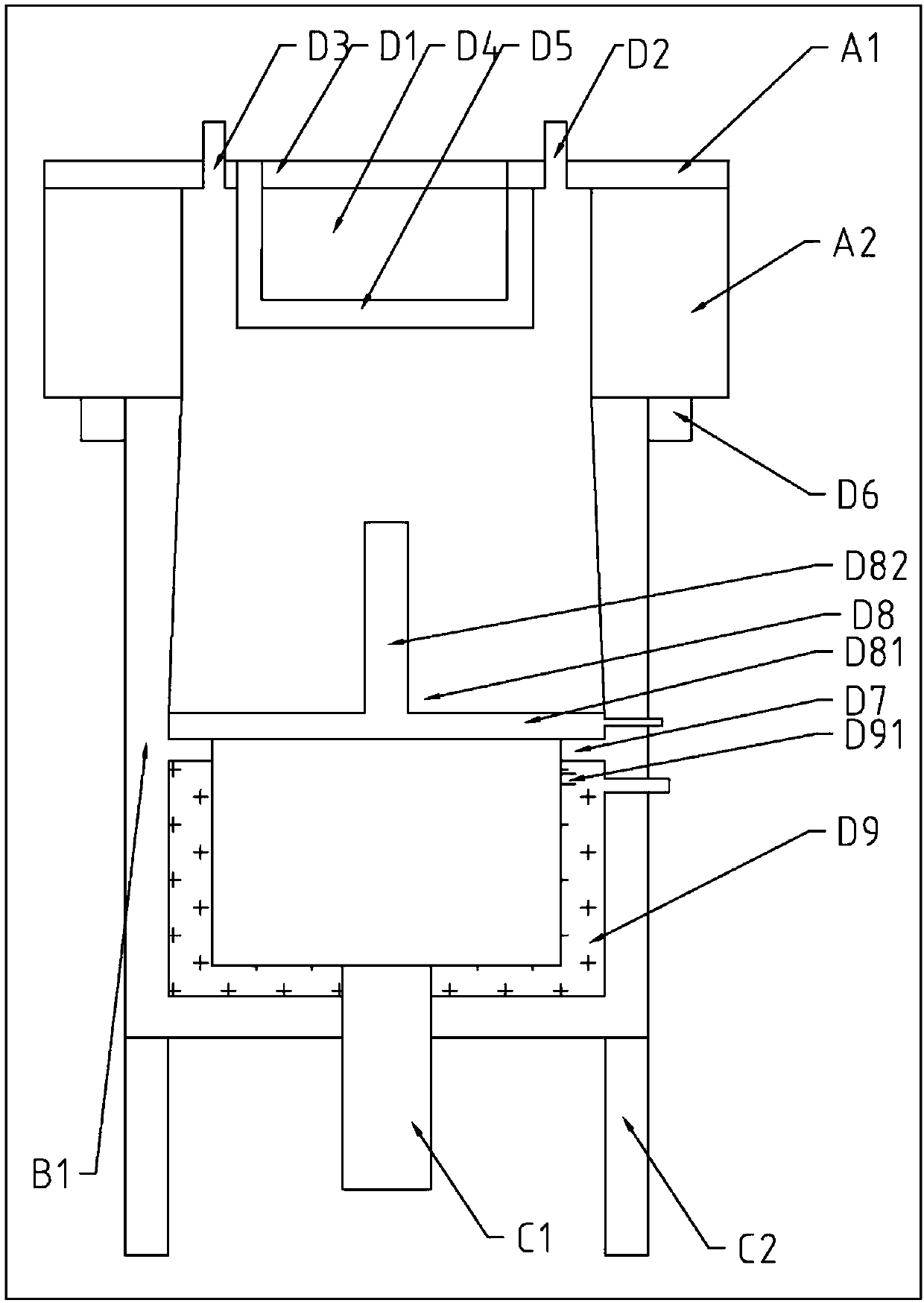

[0018] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. "About" in this application is only within 10% of the enumerated value.

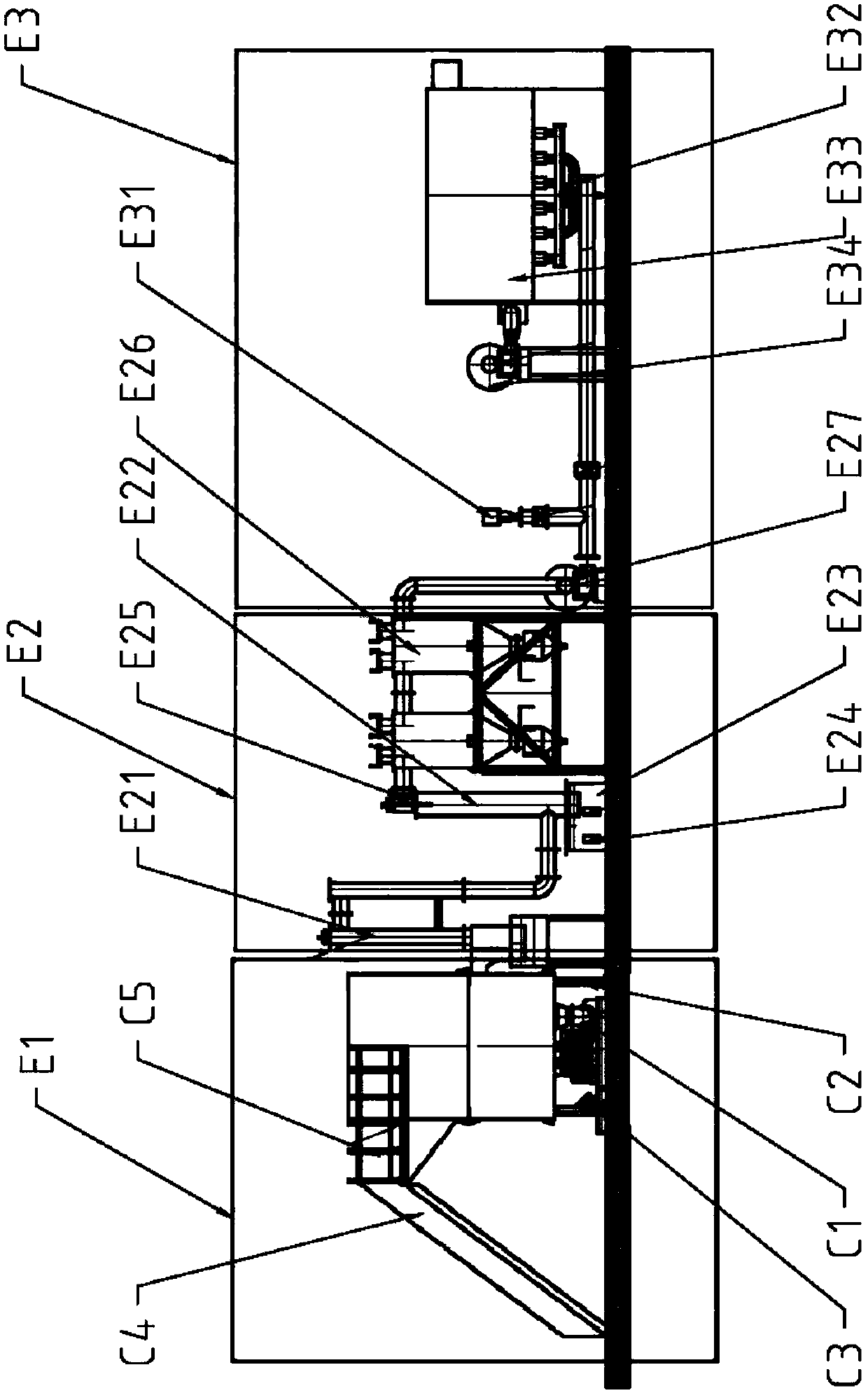

[0019] The paint slag pyrolysis process of the present invention adopts discontinuous feeding, and the paint slag is burnt and pyrolyzed in the gasification furnace to produce combustible gases such as carbon monoxide, hydrogen, methane, propane, etc., which can be used as clean energy after purification to realize The dual purpose of paint sludge disposal and providing clean energy.

[0020] The paint slag pyrolysis process of the present invention includes three major steps of pyrolysis gasification, purification, and gas reuse, wherein,

[0021] (1) The pyrolysis gasification step comprises:

[0022] (1) Raw materials are preheated and dried, and the raw materials are put into the furnace body from the top of the pyrolysis furnace. During the top-down movement of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com