A Polarizing Beam Splitter Based on Metal Grating

A technology of polarizing beam splitter and metal grating is applied in the fields of polarizing beam splitter, metal grating-based polarizing beam splitter, and optical components, which can solve the problems of manufacturing beam splitters, and achieve good polarization performance and friendly application environment. , the effect of wide spectral bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

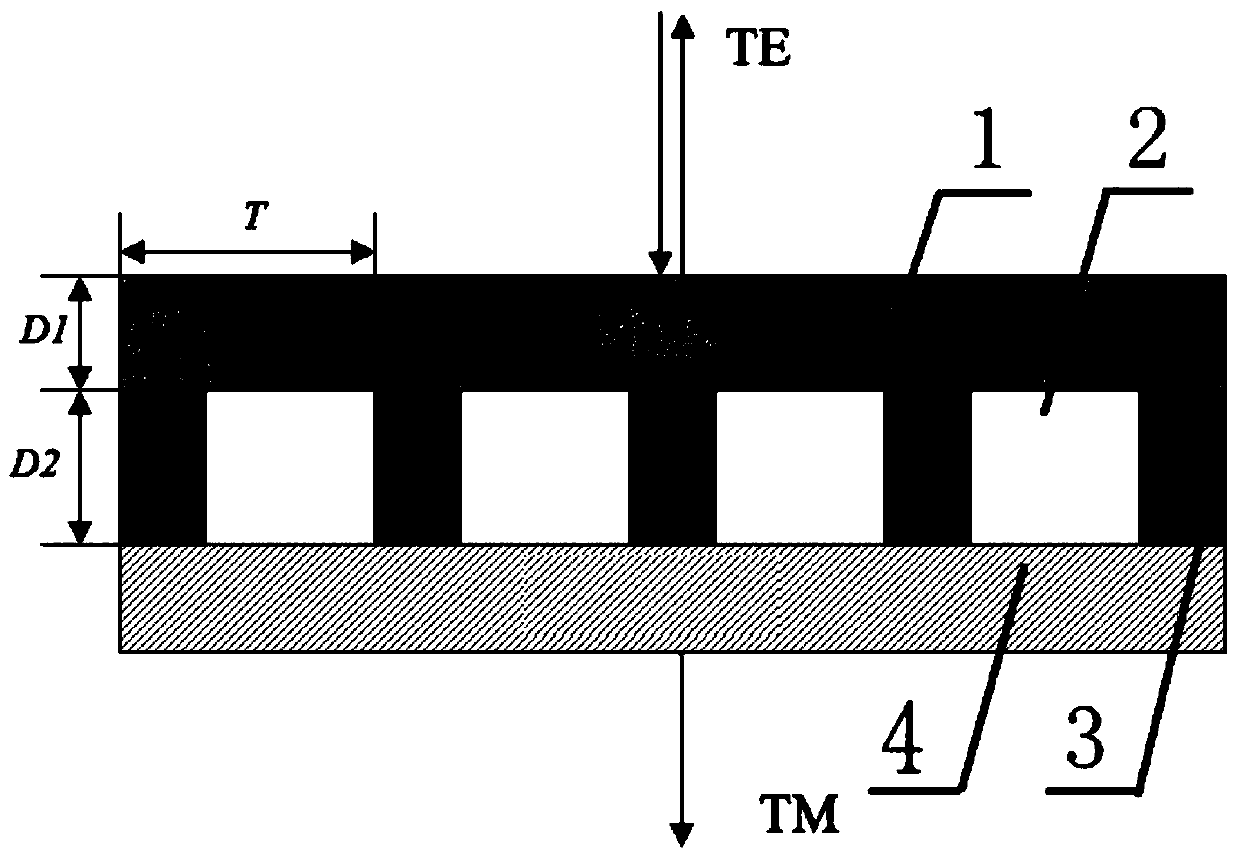

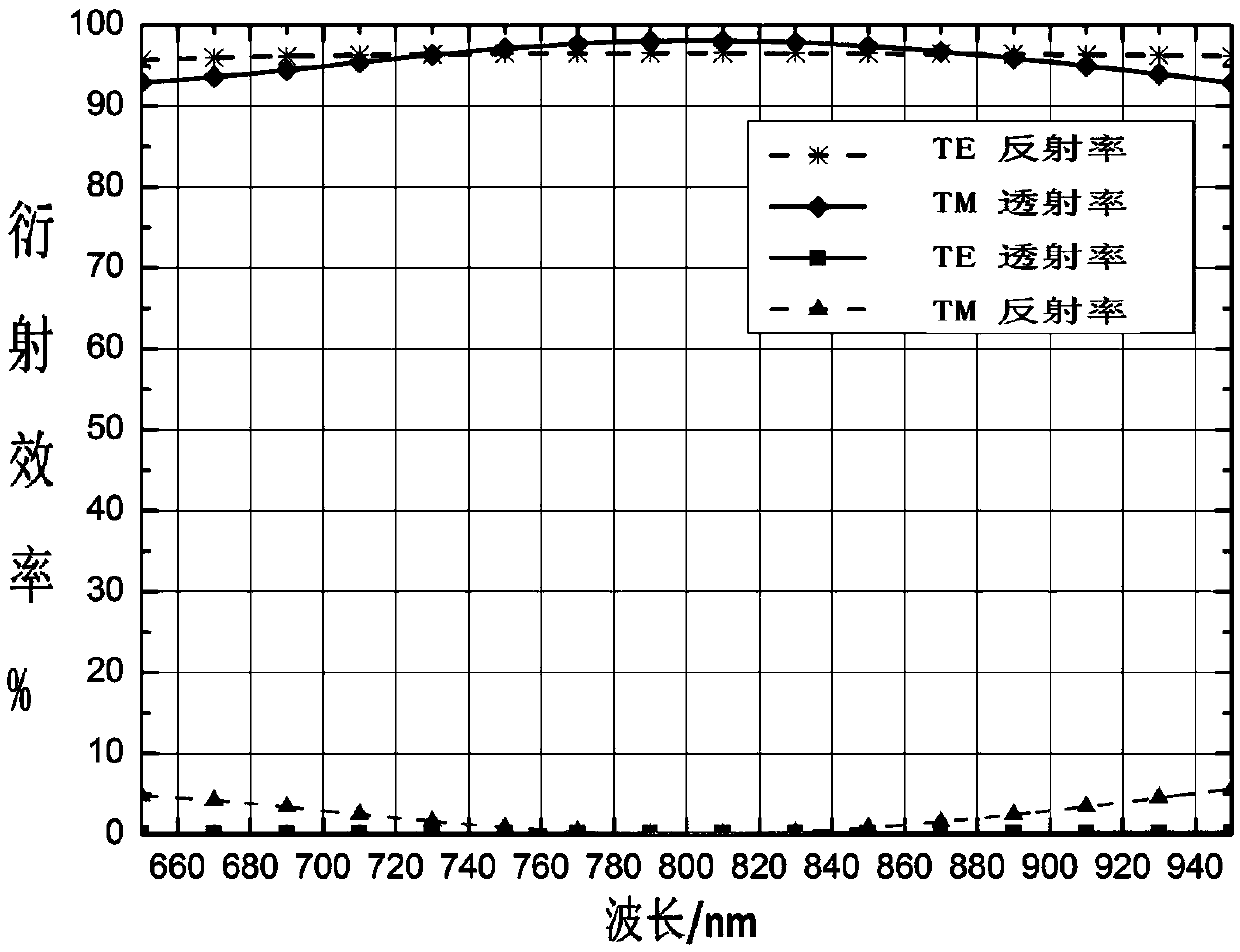

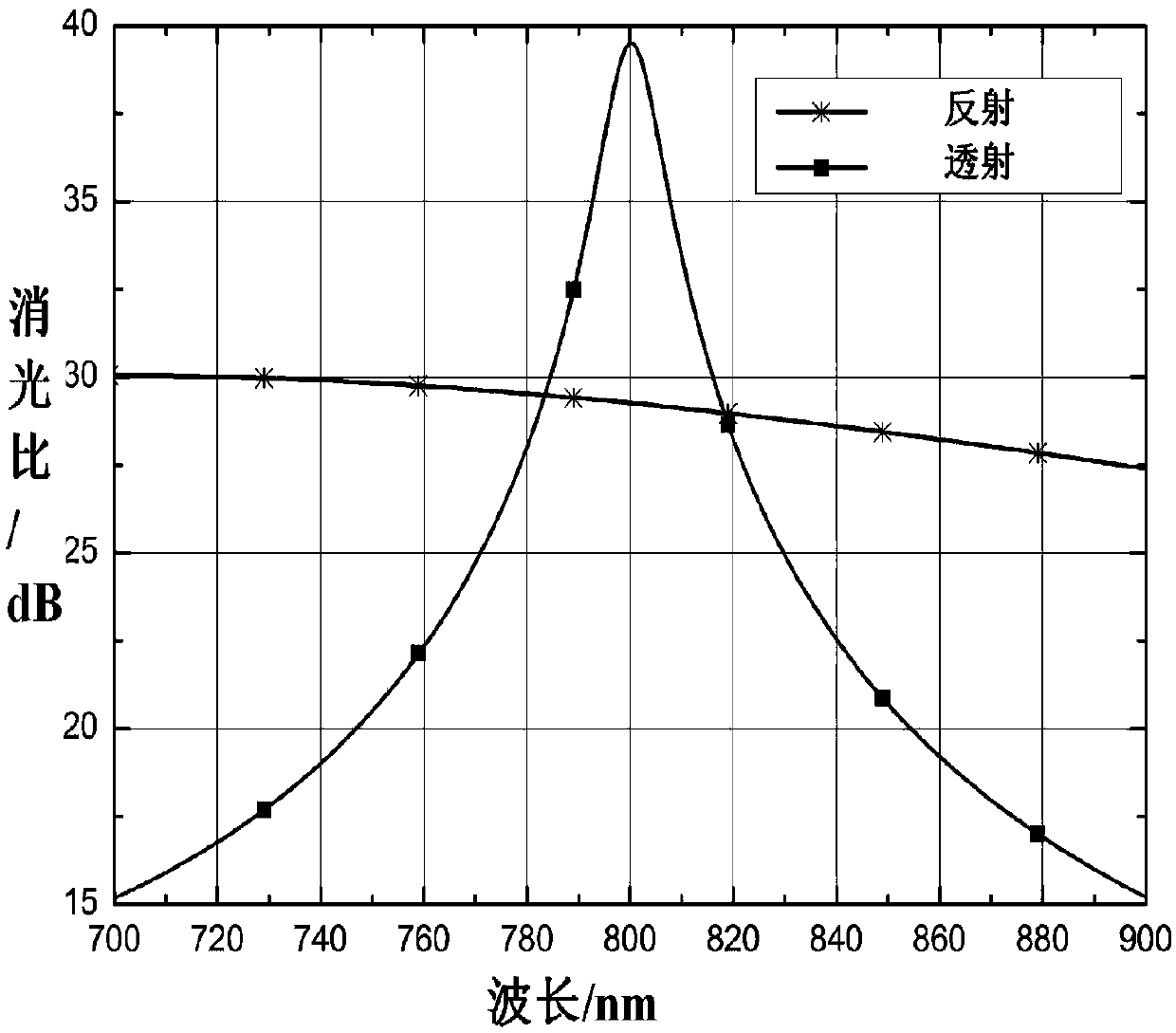

[0028] The main structure of the metal grating-based polarization beam splitter involved in this embodiment includes: a cover film layer 1, a grating structure 2, a grating groove 3 and a base 4, SiO 2 The cover film layer 1 of the material is a flat film structure, the thickness of the cover film layer 1 is 225nm, the cover film layer 1 is fixed and evenly covered on the upper surface of the grating structure, and the cover film layer 1 realizes the effect of the waveguide layer in the diffraction process of the grating structure And it can protect the grating structure 2. The upper surface of the silver grating structure 2 is made of parallel distributed grating grooves 3 by etching process. The groove depth of the grating groove 3 is 300nm, the grating duty ratio is 0.21, and the grating period is 180nm; SiO 2 The material base 4 is fixedly placed on the lower surface of the grating structure 2 to support and stabilize the grating structure 2; the main parameter design steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com