Optical fiber pre-connecting piece and terminal box therewith

A pre-connection and port-connection technology, which is applied in the field of optical fiber connection equipment, can solve problems such as delaying construction time, damaging optical fiber routing, and affecting communication signals of customers who have already opened it, and achieves improved concentricity and stability, long service life, and optical fiber. The effect of low signal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0030]

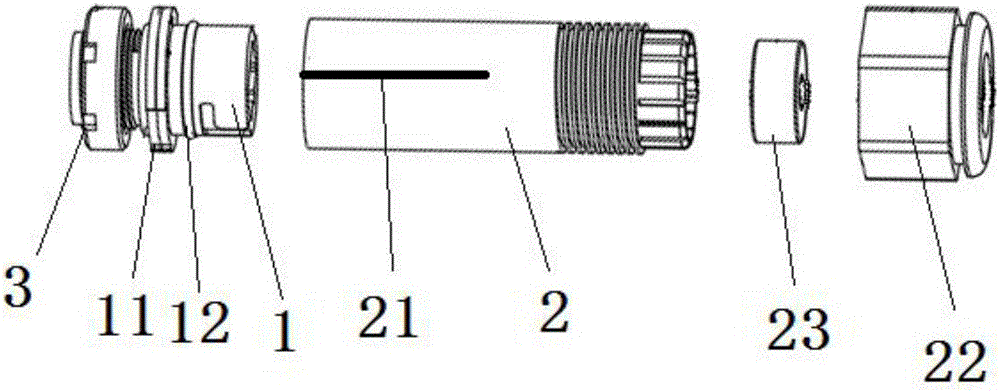

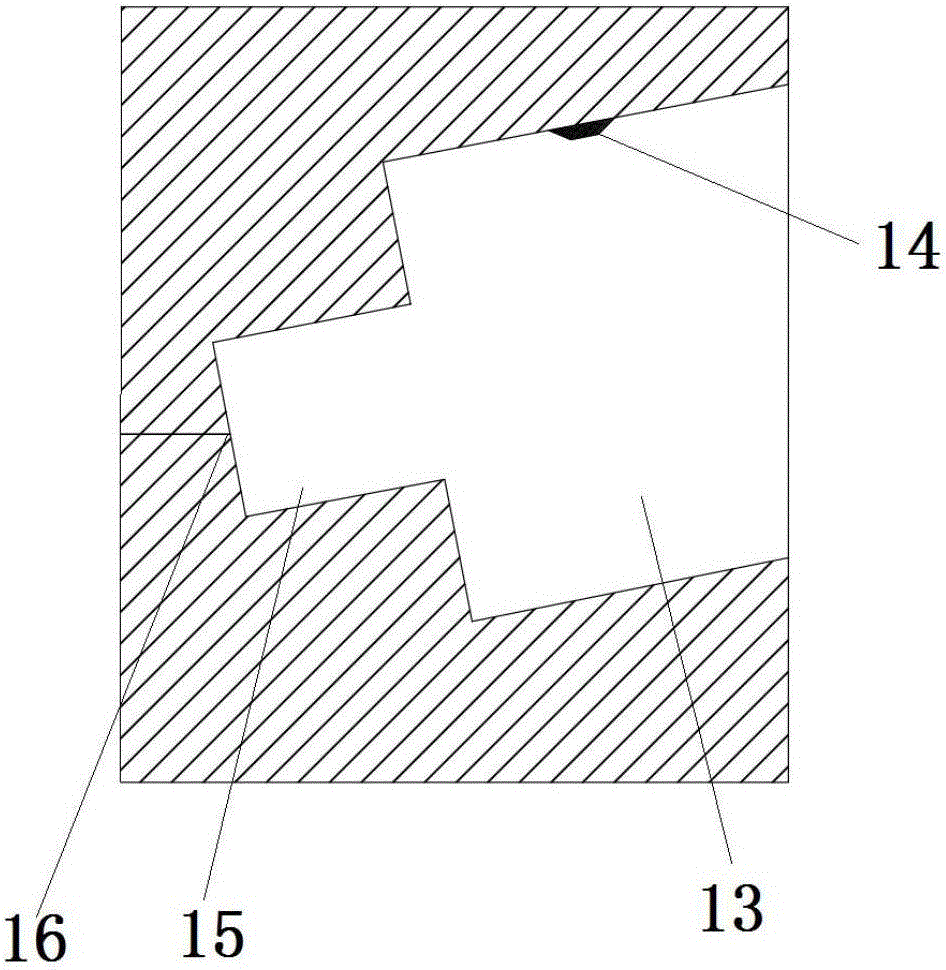

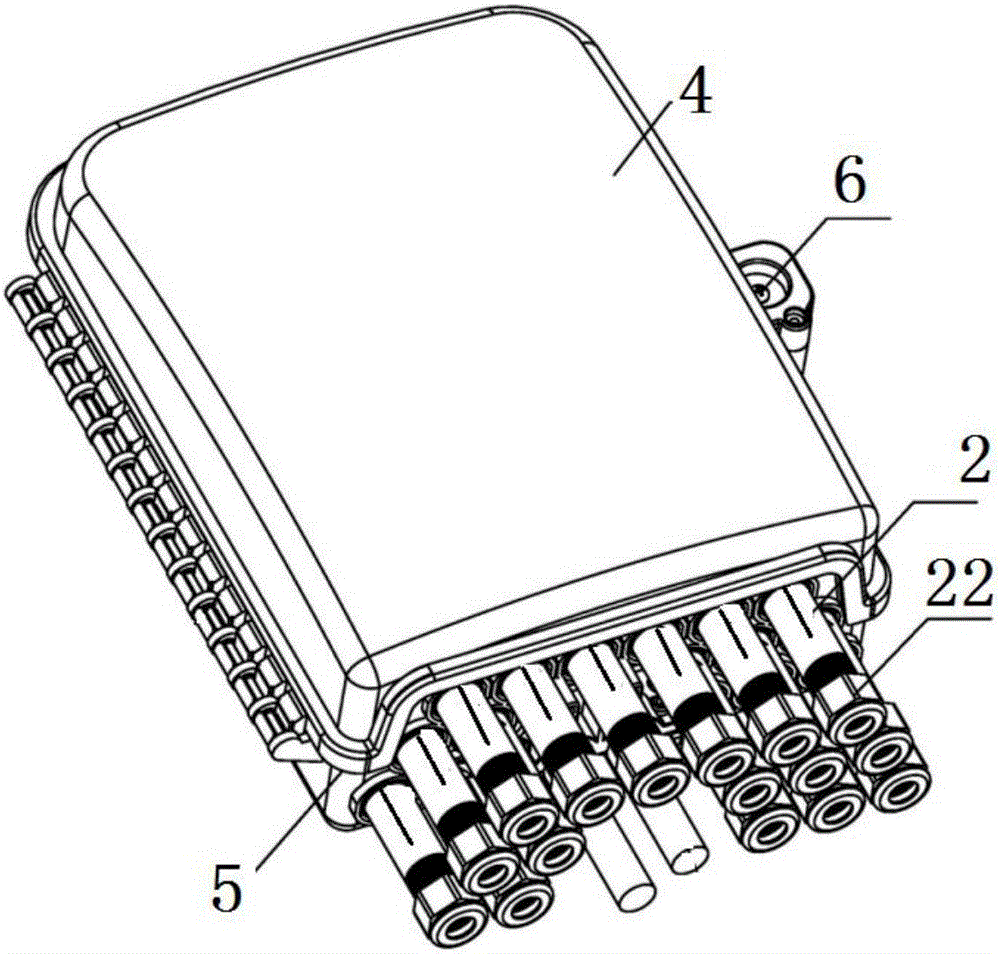

[0031] combine figure 1 As shown, the optical fiber preconnector of the present invention includes a preconnector 1 , a sealing sleeve 2 and a connecting nut 3 . The outer surface of the connecting nut 3 is provided with a slot, which can be fixed in the slot with a special wrench, and then tightened by rotating the connecting nut 3 . The inner surface is provided with threads for connecting the pre-connected joint 1 . The pre-connection joint 1 includes a threaded connection end and an optical fiber connection end, and a positioning ring 11 is arranged between the two ends. Wherein the threaded connection end has an external thread, which can be connected with the internal thread of the connecting nut 3 . The outer surface of the optical fiber connection end is provided with a card slot for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com