Cement firing process optimizing method based on clinker quality index

A quality index and process optimization technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems that production variable optimization methods cannot meet the needs of field applications, and achieve long-term stable operation, reduced maintenance costs, and generalization powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

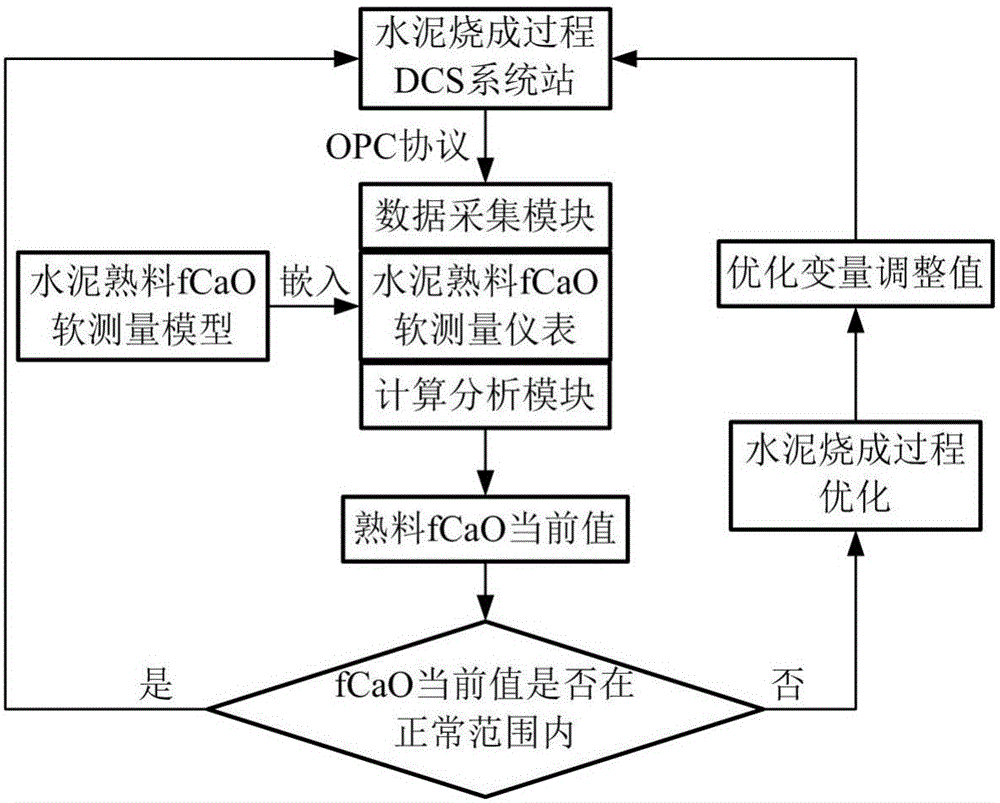

[0028] The present invention is a kind of cement firing process optimization method based on clinker quality index, and its content comprises the following steps:

[0029] Step 1 Soft sensor model of clinker fCaO content

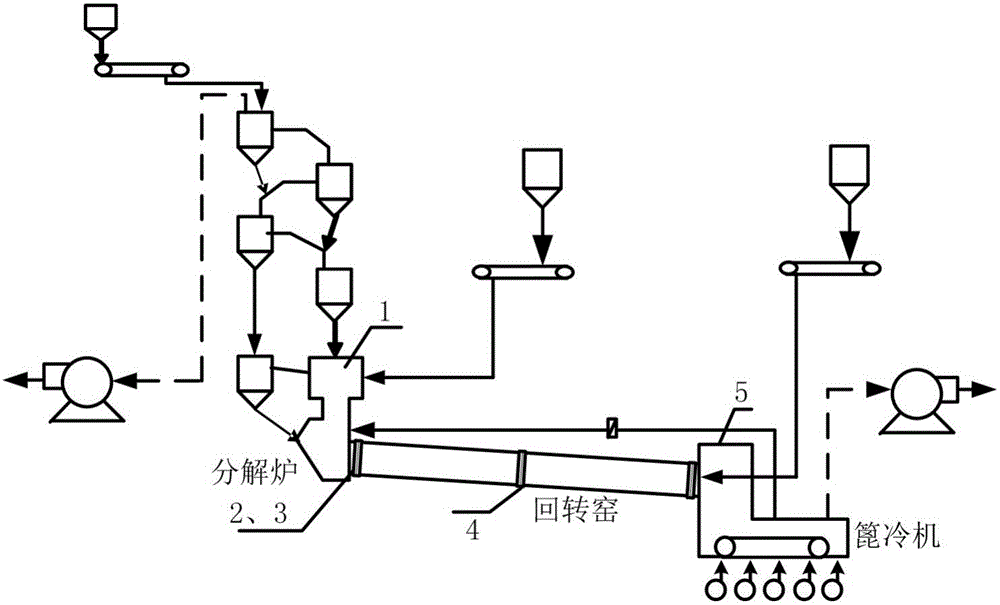

[0030] figure 1 Shown is the process diagram of the cement clinker firing process, which is composed of figure 1 From the cement production process shown, it can be seen that cement clinker is a solid particle material obtained by pre-decomposing raw meal in a calciner, high-temperature calcination in a rotary kiln, and rapid cooling by a grate cooler. Cement clinker does not participate in chemical reactions, and the calcium oxide that exists in a free state is called cement clinker free calcium oxide fCaO. The fCaO content of cement clinker has a direct impact on the stability of cement, and can indirectly reflect the firing status of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com