Lithium thionyl chloride battery positive electrode and preparation method thereof

A technology of lithium thionyl chloride battery and battery positive electrode, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc. It can solve the problems of difficult dispersion of carbon nanotubes, uneven powder, large electrode polarization, etc., and achieve It is easy to process into electrode sheets, disperse and evenly compound the amount, and increase the output voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

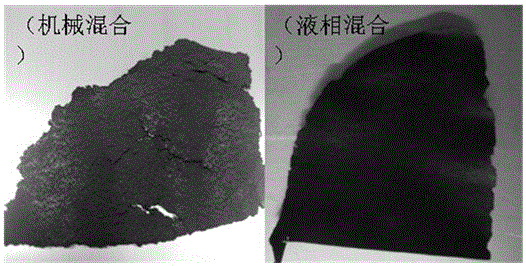

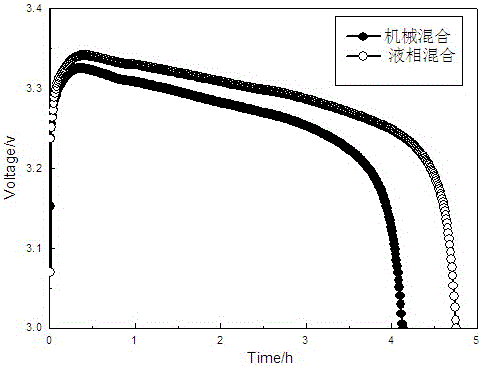

Image

Examples

Embodiment 1

[0019] Embodiment 1: a lithium thionyl chloride battery positive electrode, comprising acetylene black, carbon nanotubes and polytetrafluoroethylene emulsion, the preparation method of the electrode comprises the following steps:

[0020] (1) Mechanical ball milling: Put 90g of acetylene black and 5g of carbon nanotubes into a ball milling tank respectively, and use the method of mechanical ball milling to mill them for 1 hour respectively;

[0021] (2) Ultrasonic dispersion: add the two powders obtained in step 1) into 900ml and 100ml of deionized water respectively, then add 4.5g and 0.5g of polytetrafluoroethylene emulsion respectively, and place them in an ultrasonic cleaning machine for ultrasonic dispersion , sonicate for 30 minutes, so that the polytetrafluoroethylene and the powder are evenly dispersed in the water;

[0022] (3) Ultrasonic stirring: Mix the two dispersions obtained in step 2) and ultrasonically stir for 30 minutes at a power of 80W;

[0023] (4) Sucti...

Embodiment 2

[0027] Embodiment 2: a lithium thionyl chloride battery positive electrode, comprising acetylene black, carbon nanotubes and polytetrafluoroethylene emulsion, the preparation method of the electrode comprises the following steps:

[0028] (1) Mechanical ball milling: put 80 g of acetylene black and 15 g of carbon nanotubes into a ball milling tank, and use mechanical ball milling to mill them for 1 hour;

[0029] (2) Ultrasonic dispersion: Add the two powders obtained in step 1) into 800ml and 200ml of deionized water respectively, then add 4g and 1g of polytetrafluoroethylene emulsion respectively, place them in an ultrasonic cleaning machine for ultrasonic dispersion, and ultrasonically Treat for 30 minutes to disperse polytetrafluoroethylene and powder evenly in water;

[0030] (3) Ultrasonic stirring: Mix the two dispersions obtained in step 2) and ultrasonically stir for 30 minutes at a power of 80W;

[0031] (4) Suction filtration: Suction filtration is performed on the...

Embodiment 3

[0035] Embodiment 3: a lithium thionyl chloride battery positive electrode, comprising acetylene black, carbon nanotubes and polytetrafluoroethylene emulsion, the preparation method of the electrode comprises the following steps:

[0036] (1) Mechanical ball milling: Put 70g of acetylene black and 25g of carbon nanotubes into a ball milling tank respectively, and use the method of mechanical ball milling to mill them for 1 hour respectively;

[0037] (2) Ultrasonic dispersion: add the two powders obtained in step 1) into 700ml and 300ml of deionized water respectively, then add 3.5g and 1.5g of polytetrafluoroethylene emulsion respectively, and place them in an ultrasonic cleaning machine for ultrasonic dispersion , sonicate for 30 minutes, so that the polytetrafluoroethylene and the powder are evenly dispersed in the water;

[0038] (3) Ultrasonic stirring: Mix the two dispersions obtained in step 2) and ultrasonically stir for 30 minutes at a power of 80W;

[0039] (4) Suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com