Laminated battery cell preparation device

A technology for preparing a device and a battery cell, which is applied in the field of a stacking battery core preparation device, can solve the problems of long auxiliary time of the production process and the stacking process, many transfer times of the materials to be stacked, and bumps on the edges and corners of the pole pieces. , to achieve the effect of simplifying the transfer and handling process, improving production efficiency and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The device for preparing laminated battery cells according to the present invention will be described in detail below with reference to the accompanying drawings.

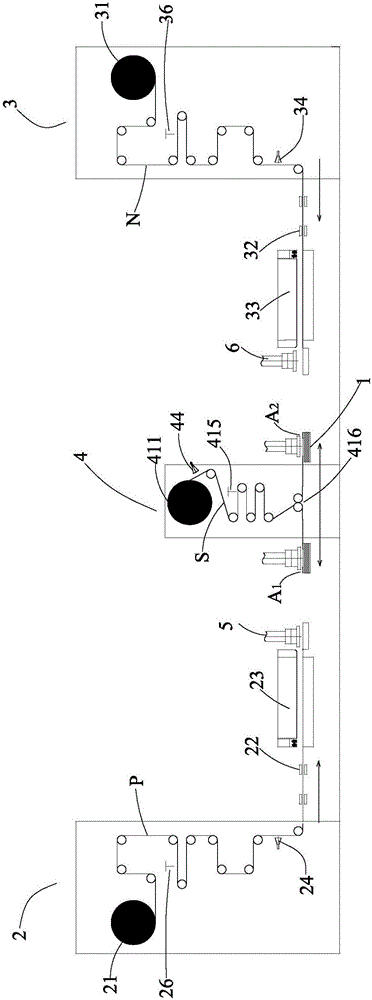

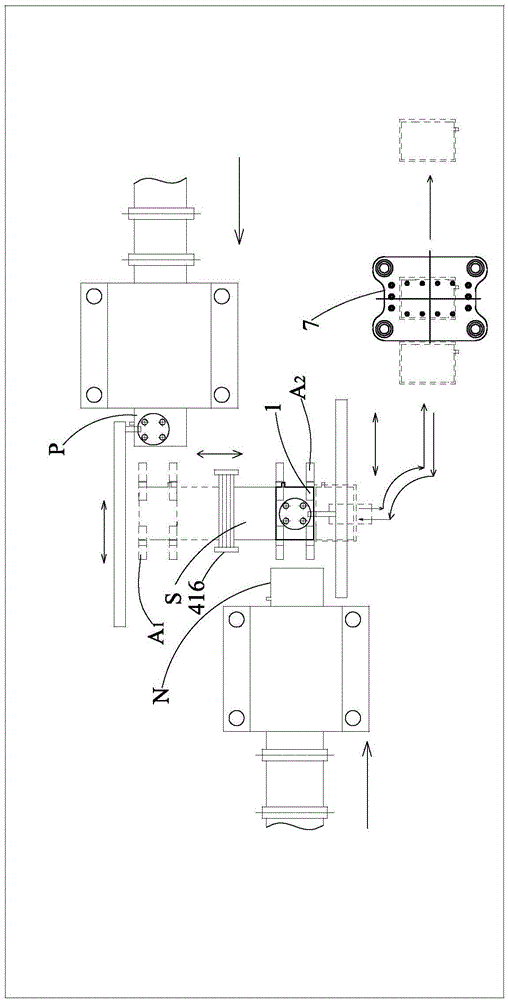

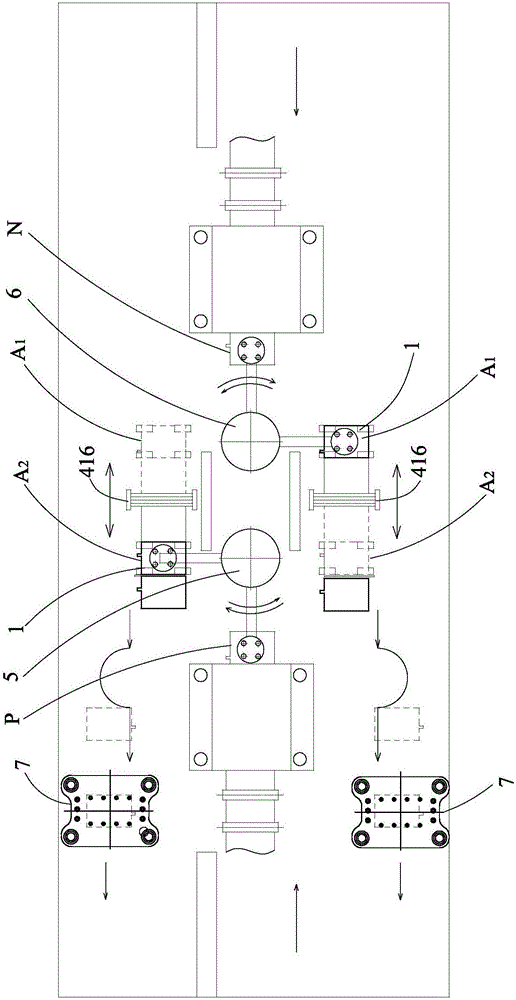

[0039] refer to Figure 1 to Figure 5 According to the present invention, the laminated cell preparation device includes: a stacking platform 1; an anode sheet making mechanism 2 for positioning and preparing anode sheets P one by one; a cathode sheet making mechanism 3 for positioning and Prepare the cathode pole pieces N one by one; the separator providing mechanism 4 is used to position the separator S and provide the separator S to the stacking platform 1 directly (without going through the material box in the traditional lamination process and without repositioning); The anode pole piece manipulator 5 is used to pick up each anode pole piece P prepared from the anode pole piece production mechanism 2 one by one and directly (without going through the material box in the traditional stacking process and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com