Ceramic heating tube and manufacturing process thereof

A ceramic heating tube and manufacturing process technology, applied in the direction of the shape of the heating element, can solve the problems of many processes, unfavorable automatic production, complexity, etc., and achieve the effects of simplifying the processing process, good high temperature oxidation resistance, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

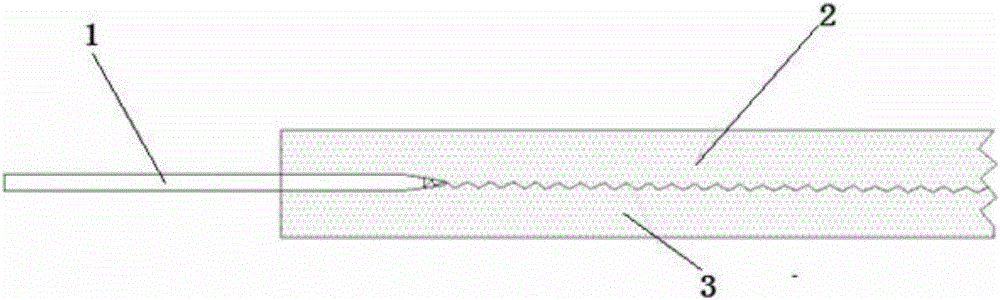

Image

Examples

Embodiment 1

[0027] The main components of the powder of ceramic 2 can be: calcium oxide 2%, silicon oxide 0.5%, aluminum oxide powder 97.5%.

Embodiment 2

[0029] The main components of the powder of ceramic 2 can be: calcium oxide 4%, silicon oxide 1.5%, aluminum oxide powder 94.5%.

Embodiment 3

[0031] The main components of the powder of the ceramic 2 can be: 3% calcium oxide, 1% silicon oxide, and 96% aluminum oxide powder.

[0032] A manufacturing process of a ceramic heating tube, comprising the following process steps:

[0033] S1: Select the heating element 3 according to the design requirements, process it into the required shape, and weld the lead rod 1;

[0034] S2: Select the corresponding mold according to the powder forming method, design shape and technical parameters of ceramic 2;

[0035] S3: Assemble the heating element 3 and the mould, cover the heating element with the powder of ceramic 2 and form it, and add water, binder, solution, which accounts for 15%-28% of the powder mass of ceramic 2 during the grouting molding process. Adhesive mixture, the mass ratio of water, binder and debonding agent is 8:1:1.

[0036] S4: Assemble other components according to design needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com