Tobacco shred fast shaping and drying method

A drying method and technology for shredded tobacco, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of low filling value, less aroma, slow drying speed, etc., and achieve the effect of increasing filling value and improving filling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

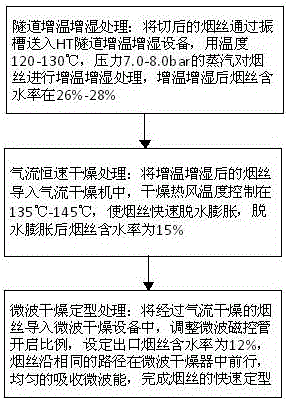

[0021] Tobacco leaves of C3F grade in 2012 were selected, cut into shreds, and then quickly shaped and dried. The specific steps are as follows:

[0022] A. Tunnel heating and humidification treatment: send the cut tobacco into the HT tunnel heating and humidification equipment through the vibrating tank, and use steam at a temperature of 125°C and a pressure of 7.5bar to heat and humidify the cut tobacco. The moisture content of cut tobacco is 26%.

[0023] B. Lead the heated and humidified shredded tobacco into an airflow dryer, and control the temperature of the drying hot air at 135°C to rapidly dehydrate and expand the shredded tobacco. The moisture content of the shredded tobacco after dehydration and swelling is 15%.

[0024] C. Microwave drying and shaping treatment: import the air-dried shredded tobacco into the microwave drying equipment, adjust the opening ratio of the microwave magnetron to 85%, set the moisture content of the outlet shredded tobacco to 12%, and cu...

Embodiment 2

[0027] Tobacco leaves of B3F grade in 2013 were selected, cut into shreds, and then subjected to rapid shaping and drying. The specific steps are as follows:

[0028] A. Tunnel heating and humidification treatment: send the cut tobacco into the HT tunnel heating and humidification equipment through the vibrating tank, and use steam at a temperature of 130°C and a pressure of 8.0bar to heat and humidify the tobacco. The moisture content of cut tobacco is 28%.

[0029] B. Lead the heated and humidified shredded tobacco into an airflow dryer, and control the temperature of the drying hot air at 140°C to rapidly dehydrate and expand the shredded tobacco. After dehydrating and expanding, the moisture content of the shredded tobacco is 15%.

[0030] C. Microwave drying and shaping treatment: import the air-dried shredded tobacco into the microwave drying equipment, adjust the opening ratio of the microwave magnetron to 85%, set the moisture content of the outlet shredded tobacco to ...

Embodiment 3

[0033] Tobacco leaves of C3F grade in 2012 were selected, cut into shreds, and then quickly shaped and dried. The specific steps are as follows:

[0034] A. Tunnel heating and humidification treatment: send the cut tobacco into the HT tunnel heating and humidification equipment through the vibrating tank, and use steam at a temperature of 130°C and a pressure of 8.0bar to heat and humidify the tobacco. The moisture content of cut tobacco is 28%.

[0035] B. Lead the heated and humidified shredded tobacco into an airflow dryer, and control the temperature of the drying hot air at 140°C to rapidly dehydrate and expand the shredded tobacco. After dehydrating and expanding, the moisture content of the shredded tobacco is 15%.

[0036] C. Microwave drying and shaping treatment: import the air-dried shredded tobacco into the microwave drying equipment, adjust the opening ratio of the microwave magnetron to 85%, set the moisture content of the outlet shredded tobacco to 12%, and cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com