Ultrasonic atomization deacidification dedusting system

A dust removal system, ultrasonic technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of short service life, entering the smoke chamber, long-term intrusion, etc., to prevent precipitation and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

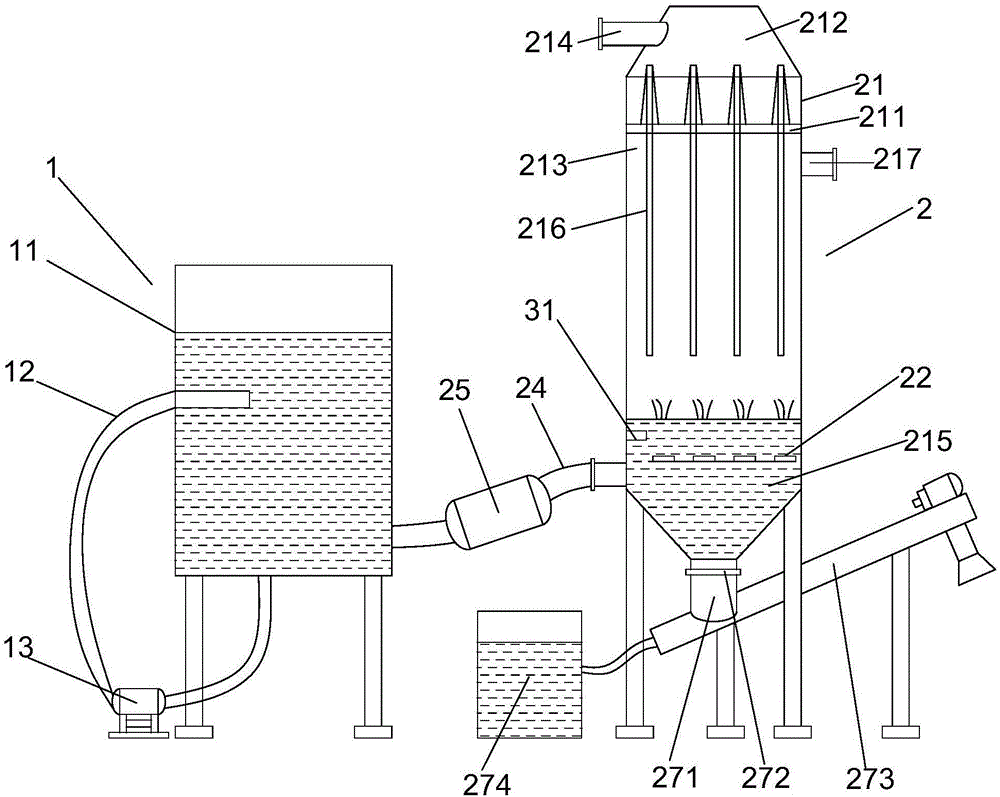

[0017] Such as figure 1 As shown, the present invention proposes an ultrasonic atomization deacidification and dust removal system, comprising a lye disposing device 1, and the lye disposing device 1 comprises: a dispensing barrel 11 for containing lye; 11 is connected to the bottom, and its other end is connected to the middle part of the configuration barrel 11; and the liquid return pump 13 is arranged on the liquid return pipeline 12, and its liquid inlet is connected to the bottom of the configuration barrel 11 through the liquid return pipeline 12, and its liquid outlet passes through The liquid return pipeline 12 communicates with the middle part of the configuration barrel 11 to circulate the lye in the configuration barrel 11.

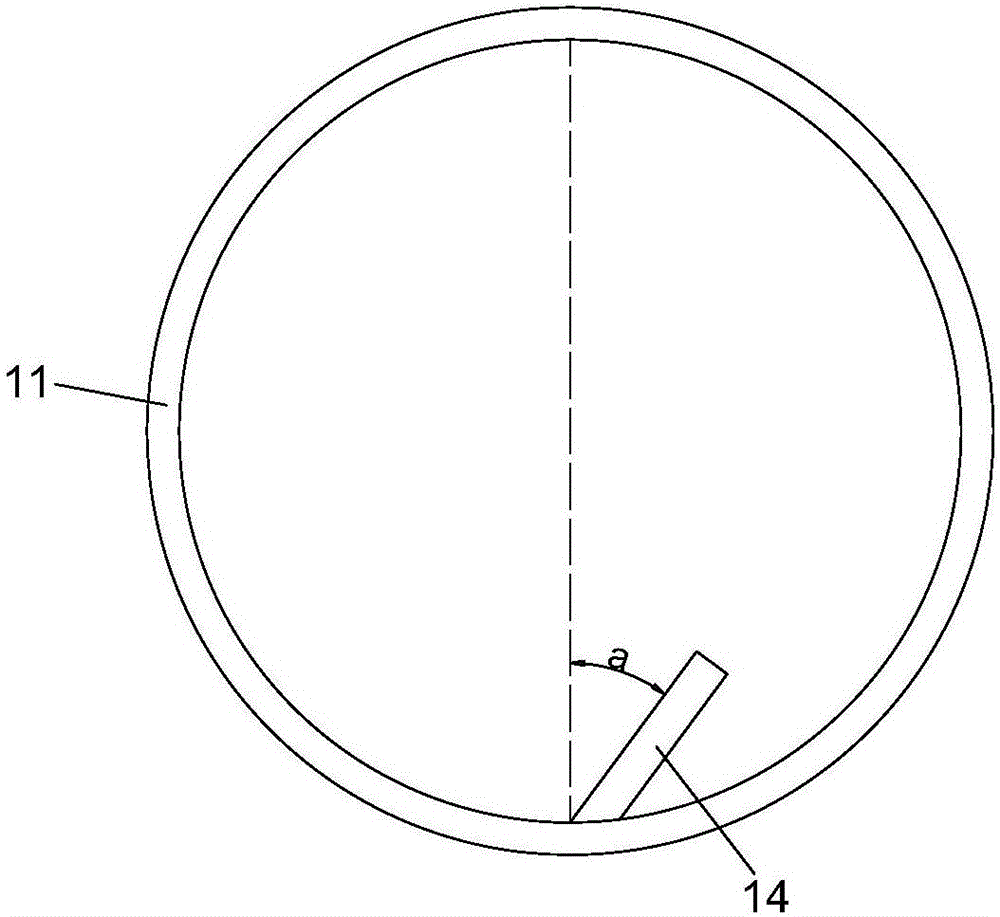

[0018] Such as figure 2 As shown, in order to form a vortex in the configuration barrel 11 after the return liquid pipeline 12 returns liquid, so that the lye is mixed more evenly during rotation, the configuration barrel 11 is a cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com