N-alkane isomerization catalyst and preparation method thereof

A technology of n-alkane and catalyst, which is applied in the field of n-alkane isomerization catalyst and its preparation, can solve the problems of selectivity and catalytic activity that cannot meet the requirements of n-alkane isomerization, and achieve high catalytic activity and multi-branched The effect of isomerization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

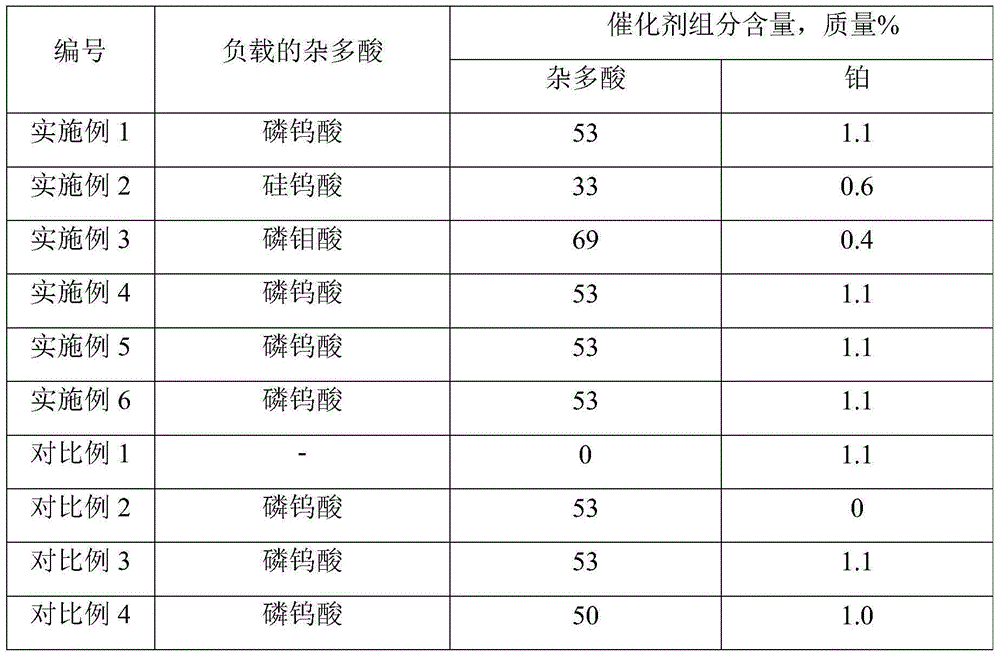

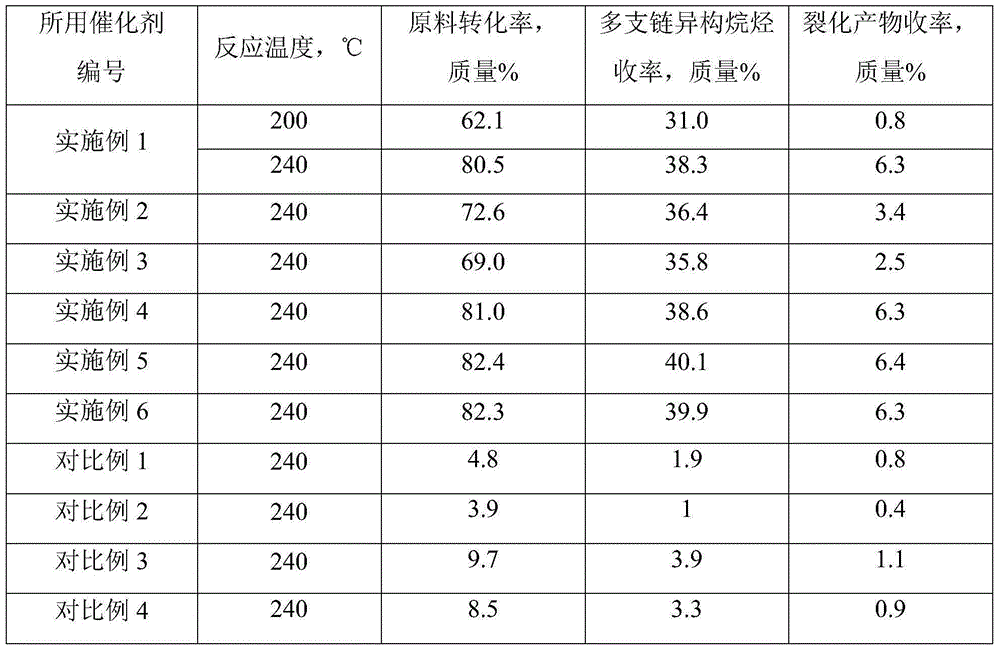

[0017] The present invention provides a preparation method of n-alkane isomerization catalyst, comprising the following steps: (1) impregnating an alumina carrier with an aqueous solution of polyol and drying to obtain an alumina carrier treated with polyol; wherein the aqueous solution of polyol is The mass ratio of the contained polyalcohol and alumina support is 1-20 mass %; The concentration of the aqueous solution of polyalcohol is 1-15 mass %; (2) the alumina support that the polyalcohol treatment that obtains in step (1) is in Treating at 200-300° C. for 0.1-10 hours under an inert gas atmosphere to obtain the first intermediate; (3) supporting the active metal component platinum on the first intermediate obtained in step (2), and then drying to obtain the second Two intermediates; (4) reducing the second intermediate obtained in step (3) to obtain a third intermediate; (5) loading the heteropoly acid on the third intermediate obtained in step (4) , and then dried to ob...

Embodiment 1

[0036] Put 12.2g of xylitol solution with a concentration of 1.6% by weight in a rotary evaporator, add 10g of γ-Al 2 o 3 , impregnated at 60°C for 2 hours, and then rotary evaporated to dryness at 90°C for 2 hours to obtain an alcohol-treated carrier, which was loaded into a reactor and kept at 300°C for 2 hours under a nitrogen atmosphere to obtain the first intermediate.

[0037] Put the first intermediate above into a rotary evaporator, add 15 mL of chloroplatinic acid solution with a platinum content of 7.18 mg / mL, soak at 60°C for 4 hours, and then evaporate to dryness at 90°C to obtain the second intermediate.

[0038] The above-mentioned second intermediate is loaded into the reactor and subjected to reduction treatment to obtain the third intermediate, wherein the conditions of the reduction treatment include: the volume space velocity of hydrogen is 1200 hours -1 , the reduction temperature is 200°C, and the reduction time is 4 hours.

[0039] Then use 15mL of 0.35...

Embodiment 2

[0041] Put 12.9 g of sorbitol solution with a concentration of 7% by weight into a rotary evaporator, add 10 g of η-Al 2 o 3 , impregnated at 60° C. for 2 hours, and then evaporated to dryness at 90° C. to obtain an alcohol-treated carrier, which was loaded into a reactor, and kept at 300° C. for 2 hours under a nitrogen atmosphere to obtain the first intermediate.

[0042] Put the first intermediate above into a rotary evaporator, add 8 mL of chloroplatinic acid solution with a platinum content of 6.88 mg / mL, soak at 60°C for 4 hours, and then evaporate to dryness at 90°C to obtain the second intermediate.

[0043] The above-mentioned second intermediate is loaded into the reactor and subjected to reduction treatment to obtain the third intermediate, wherein the conditions of the reduction treatment include: hydrogen volume space velocity is 5 hours -1 , the reduction temperature is 100°C, and the reduction time is 10 hours.

[0044] Then, 8 mL of 0.41 g / mL silicotungstic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com