Flexible vice clamp

A vise clamping and flexible technology, applied in vise, manufacturing tools, etc., can solve the problems of not being able to meet the clamping requirements of special parts, affecting the efficiency of product processing, and the narrow application range of ordinary vise, so as to shorten the processing preparation cycle , Production preparation is fast and convenient, and the effect of improving the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present application will be further described below in conjunction with the accompanying drawings, but the actual production structure of the present application is not limited to the following embodiments.

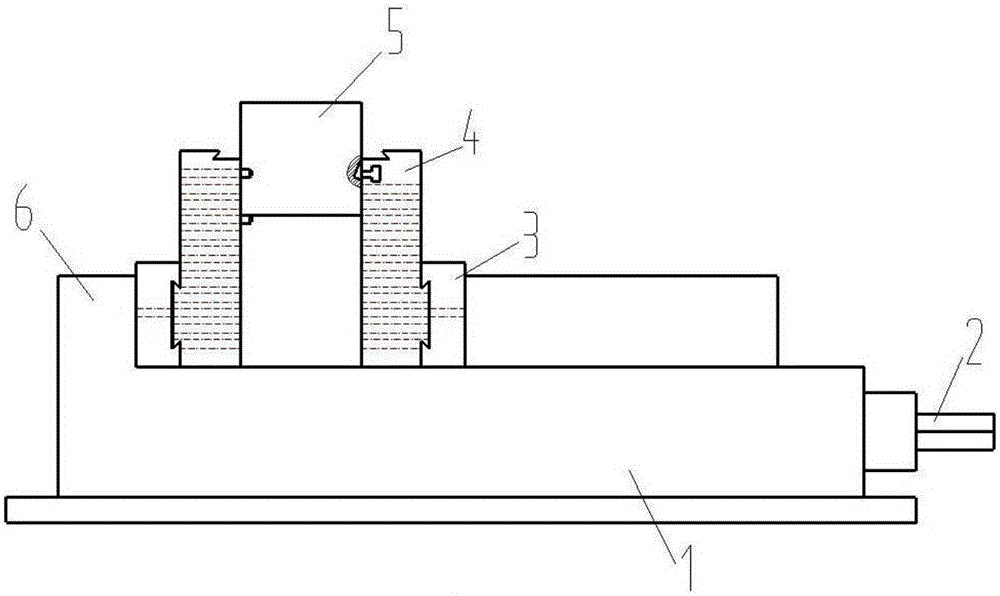

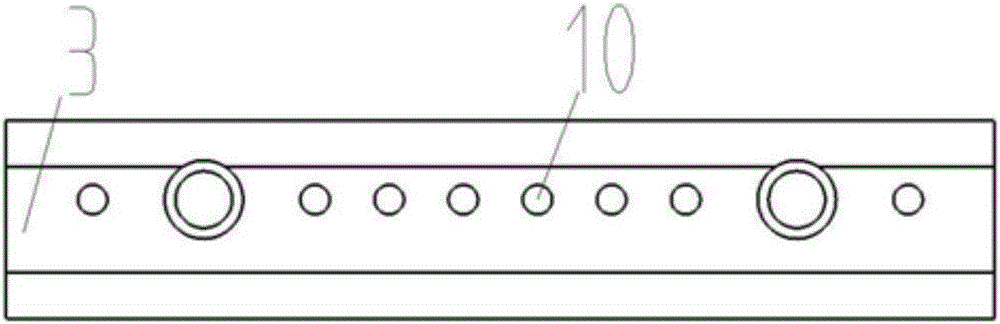

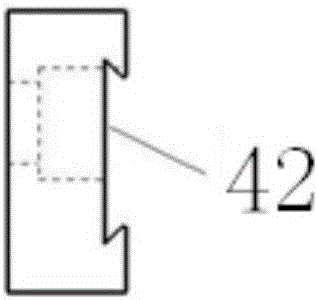

[0024] see figure 1 , the flexible vise fixture described in the application is composed of a base 1, a fixed jaw base 6 installed on the base 1, a movable jaw base 3, and a vise jaw 4 arranged on the two bases, and the movable jaw The mouth base 3 can move relative to the fixed jaw base 6 under the drive of the base adjusting screw 2, so as to clamp and release the parts 5. The structure of the jaw base is as figure 2 and image 3 Shown, have dovetail groove 42 on the inner surface of base, realize locking position with long positioning mandrel 7 and corresponding coordinate positioning hole on the vise jaw 4 that needs to change dress in the limit pin hole 10 of base. The basic structure of the vise jaw 4 is shown in Figure 4 and Figure 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com