Double-row compound bearing wheel set crawler-type moving chassis damping traveling mechanism

A traveling mechanism and mobile chassis technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as high requirements for machining and assembly processes, damage to load-bearing wheels and track mechanisms, and protection of tracked mobile chassis. Achieving the effects of good passability, extended service life and smooth passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will now be described in further detail with reference to the drawings.

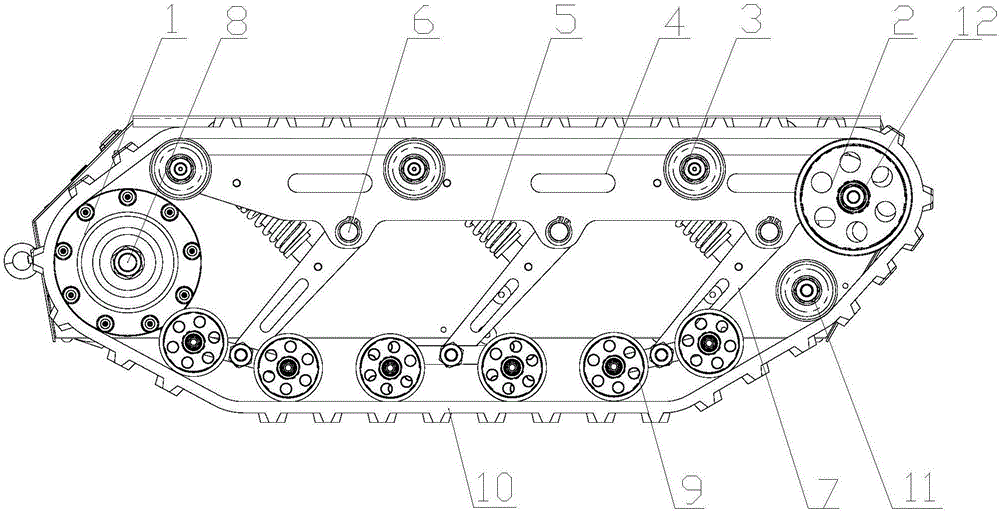

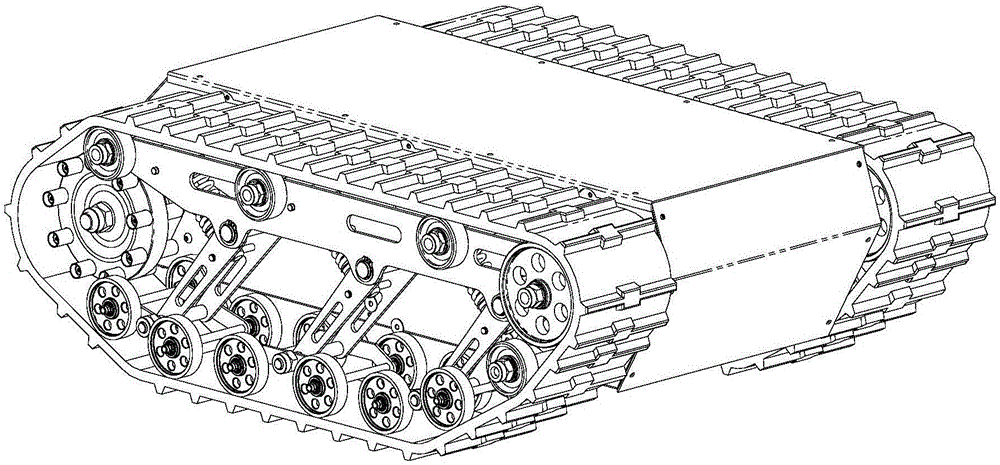

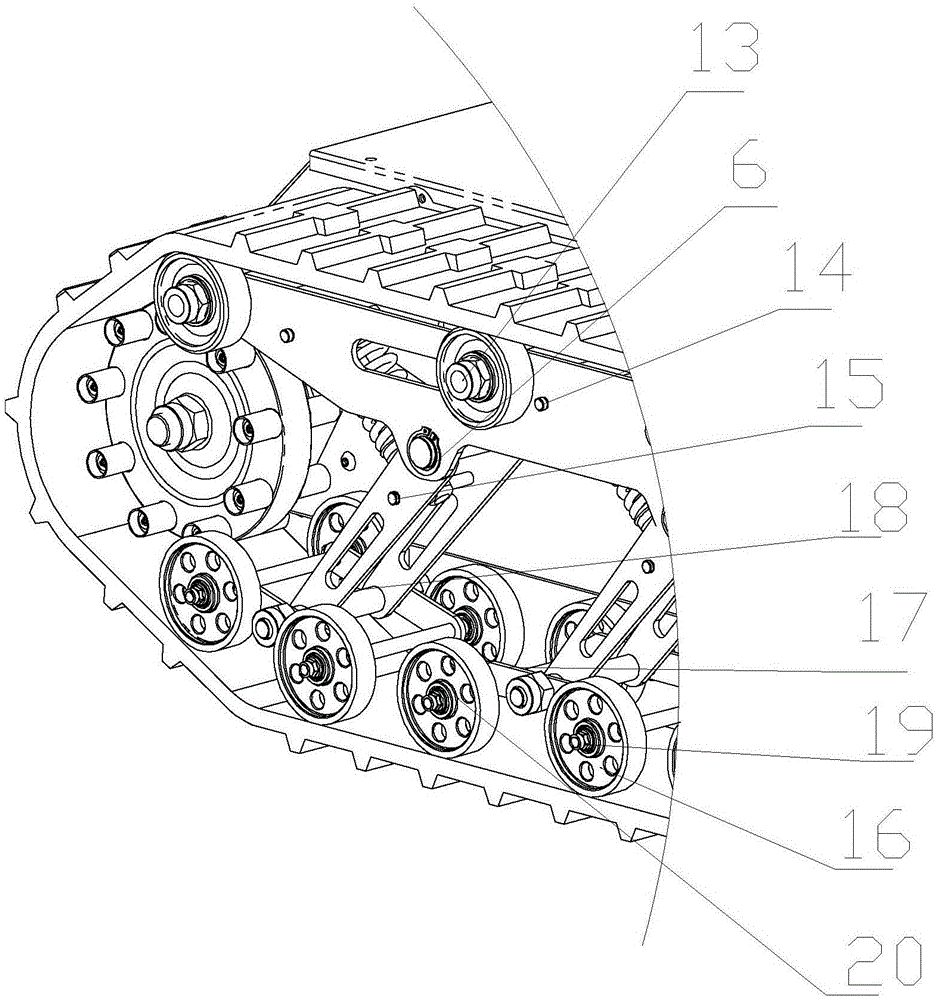

[0023] Such as figure 1 , 2 As shown, a double-row composite load-bearing wheel set crawler-type mobile chassis shock-absorbing walking mechanism includes a driving wheel set 1, a driven wheel set 2, a guide wheel set 3, a double row composite load-bearing wheel set 9, a fixed crane 4 frames, and a crawler. 10. The driving wheel set 1, the driven wheel set 2, the guide wheel set 3, and the double row composite load-bearing wheel set 9 are all located on the inner side of the crawler belt 10 and meshingly connected with the crawler belt 10. The tight wheel group 11 and the driving wheel group 1 are connected to the main motor through the driving axle 8 to provide the power for the crawler 10 to move forward. It is directly realized through the primary transmission, and the power output is obvious, which greatly improves the transmission efficiency of the motor and improves the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com