Hot mixed asphalt mixture seam plaster for alleviating pavement cracks and preparation method thereof

A technology for hot-mix asphalt and pavement cracks, applied in building insulation materials, building components, buildings, etc., can solve the problems of increasing maintenance costs and increasing maintenance workload, achieve significant social and economic benefits, and avoid easy delamination , the effect of easy flow processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

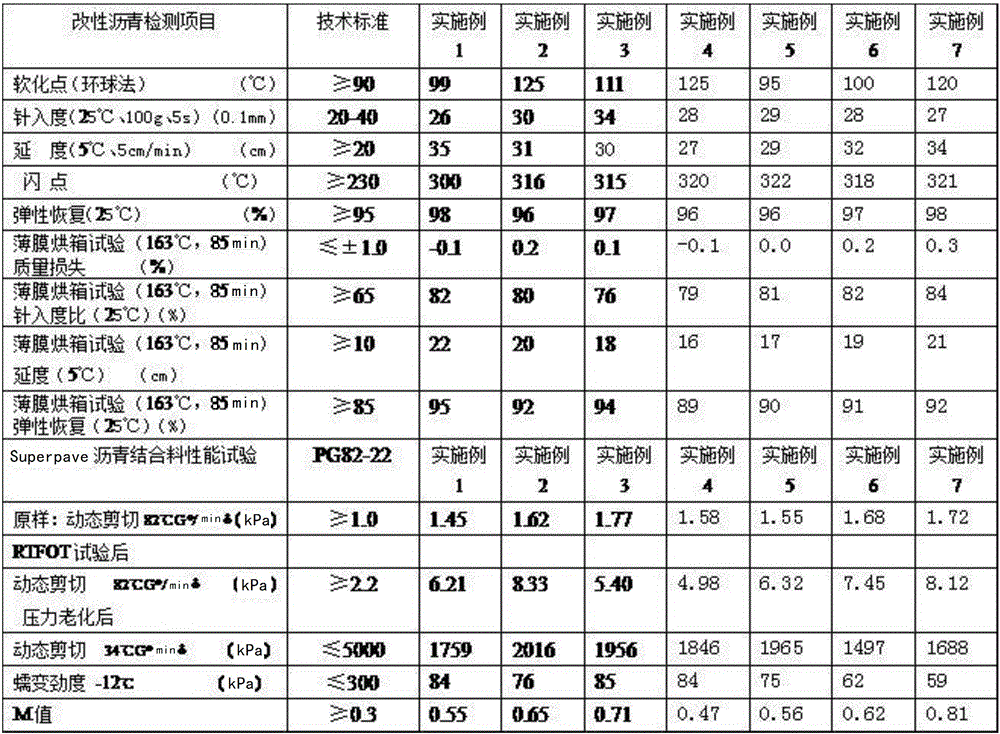

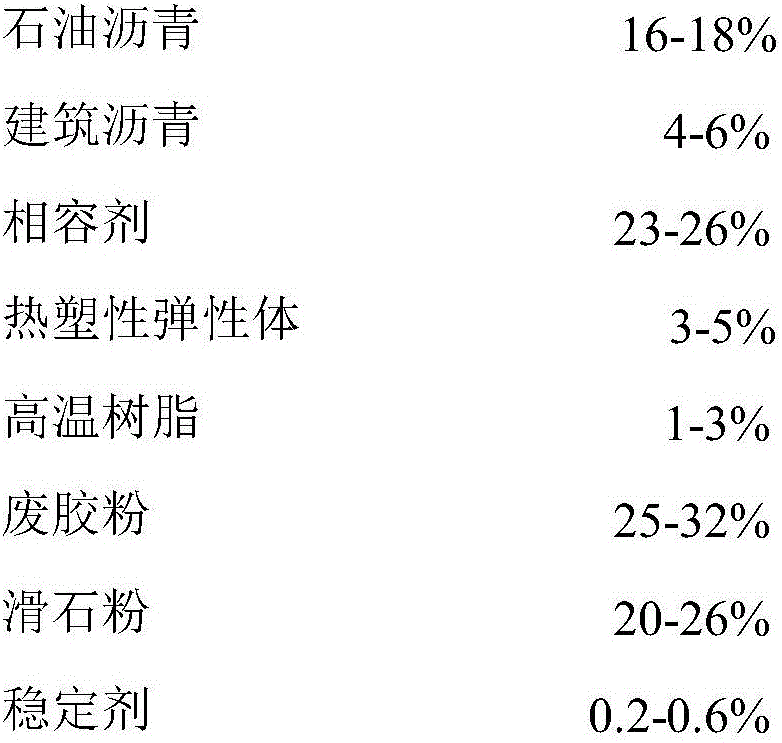

Embodiment 1

[0020] The added components and quantities are shown in Table 1, and the specific steps are as follows: 1) Preparation of prefabricated mixed asphalt: heating petroleum asphalt to 160°C, transporting and putting into construction asphalt at 155°C and mixing; 2) Stabilizer Preparation: put lignin fiber, metal soap, stearamide and sulfur into a mixer, grind at 80°C for 1.5h to prepare a stabilizer; the particle size of the stabilizer is less than 100 mesh; 3) heat the mixed asphalt to 180 ℃, put it into the working tank, and supplement the compatibilizer; 4) Add thermoplastic elastomers and high-temperature resins into the working tank while stirring and pass through the colloid mill to obtain the mixture A; 5) Put the mixture A into the development Horizontal tank, using a screw conveyor to add waste rubber powder to the development horizontal tank, after the waste rubber powder and asphalt are mixed and fused, add talcum powder, and finally add a stabilizer, stir and develop at...

Embodiment 2

[0022] The added components and quantities are shown in Table 1, and the specific steps are as follows: 1) Preparation of prefabricated mixed asphalt: heating petroleum asphalt to 165°C, transporting and putting into construction asphalt and mixing at 160°C; 2) Stabilizer Preparation: put lignin fiber, metal soap, stearamide and sulfur into a mixer, grind at 80°C for 0.5h to prepare a stabilizer; the particle size of the stabilizer is less than 100 mesh; 3) heat the mixed asphalt to 190 ℃, put it into the working tank, and supplement the compatibilizer; 4) Add thermoplastic elastomers and high-temperature resins into the working tank while stirring and pass through the colloid mill to obtain the mixture A; 5) Put the mixture A into the development Horizontal tank, using a screw conveyor to add waste rubber powder to the development horizontal tank, after the waste rubber powder and asphalt are mixed and fused, add talcum powder, and finally add stabilizer, stir and develop at 1...

Embodiment 3

[0024] The added components and quantities are shown in Table 1, and the specific steps are as follows: 1) Preparation of prefabricated mixed asphalt: heating petroleum asphalt to 170°C, transporting and putting into construction asphalt and mixing at 165°C; 2) Stabilizer Preparation: put lignin fiber, metal soap, stearamide and sulfur into a mixer, and grind at 70° C. for 1.5 hours to prepare a stabilizer; the particle size of the stabilizer is less than 100 mesh. 3) Heat up the mixed asphalt to 200°C, pour it into the working tank, and supplement the compatibilizer; 4) Add thermoplastic elastomer and high-temperature resin into the working tank while stirring and pass through the colloid mill to shear and grind to obtain the mixture A; 5) Put the mixture A into the development horizontal tank, add waste rubber powder into the development horizontal tank with a screw conveyor, stir the waste rubber powder and asphalt until they are evenly mixed, add talcum powder, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com