Molybdenum alloy with high strength and ductility and preparation method thereof

A tough molybdenum and alloy technology, applied in the field of high-strength tough molybdenum alloy and its preparation, molybdenum alloy, can solve the problems of insufficient comprehensive performance and single performance of molybdenum alloy, and achieve the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a high-strength and tough molybdenum alloy, which is made of the following raw materials in parts by weight: 5.0 g of titanium hydride, 0.8 g of zirconium hydride, 0.4 g of magnesium powder, and 1000 g of molybdenum powder.

[0030] The preparation method of the high strength and toughness molybdenum alloy of the present embodiment comprises the following steps:

[0031] Step 1, one-time mixing: mix the titanium hydride, zirconium hydride and magnesium powder with a three-dimensional mixer for 1 hour according to the formula ratio;

[0032] Step 2, secondary mixing: mix the titanium hydride, zirconium hydride, magnesium powder and molybdenum powder evenly for another 2-4 hours;

[0033] Step 3, ball milling: put the powder after secondary mixing into a ball mill tank, fill it with argon, and mill it in a low-energy ball mill with a rotation speed not higher than 200r / min for 2 hours;

[0034] Step 4, pressing: the powder after ball milling is f...

Embodiment 2

[0058] This embodiment provides a high-strength and tough molybdenum alloy, which is made of the following raw materials in parts by weight: 10.0 g of titanium hydride, 1.0 g of zirconium hydride, 0.2 g of magnesium powder, and 1000 g of molybdenum powder.

[0059] The preparation method of the high-strength and toughness molybdenum alloy of this embodiment is basically the same as that of Embodiment 1.

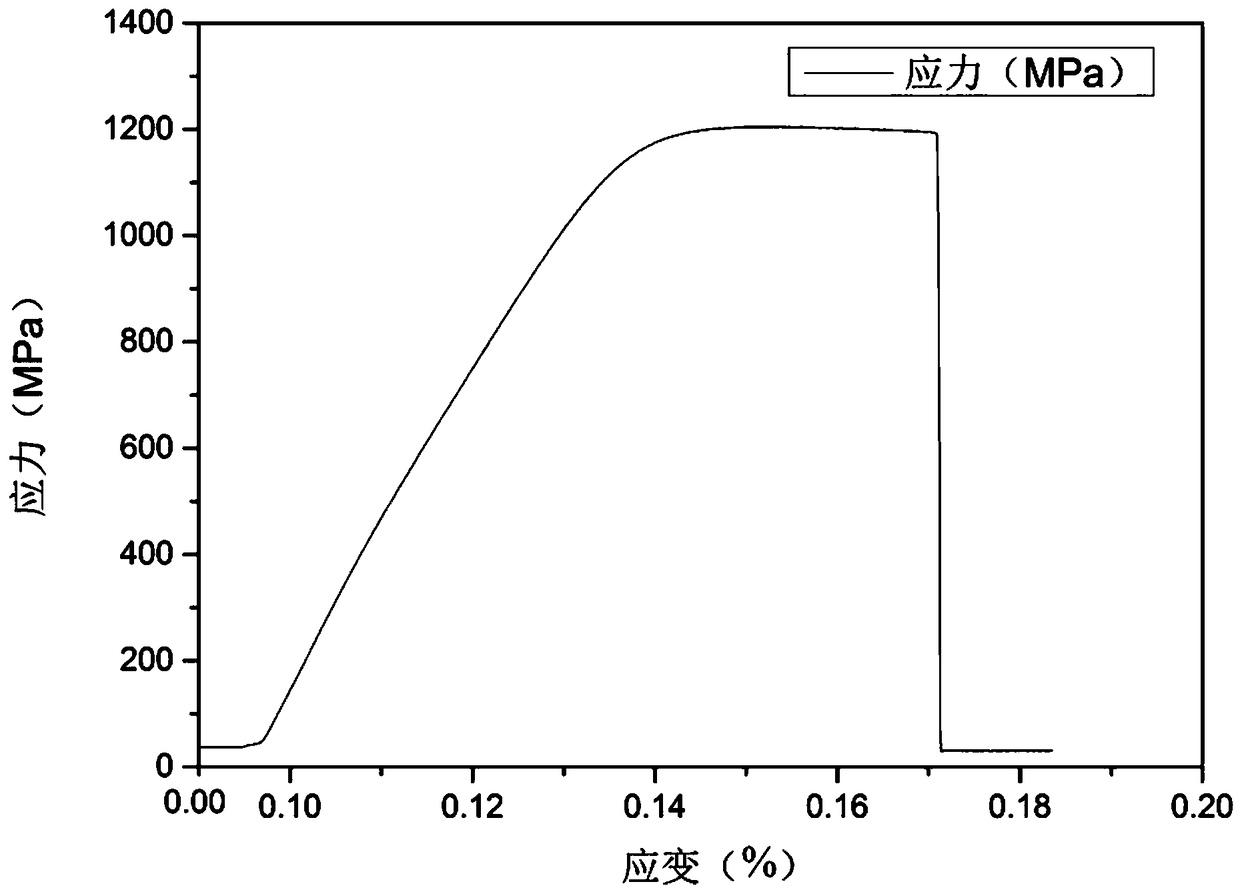

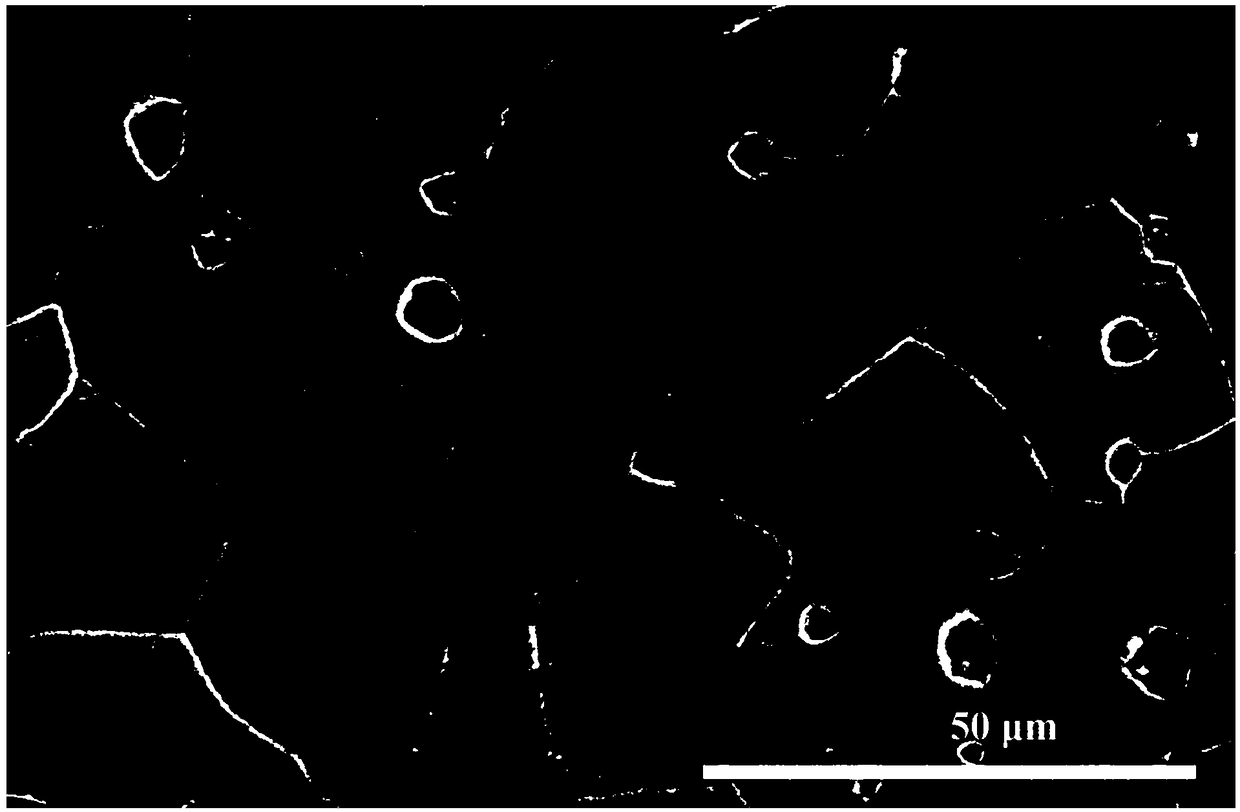

[0060] The high-strength toughness molybdenum alloy tensile curve of the present embodiment and figure 1 Basically the same, the SEM photo of the high-strength and toughness molybdenum alloy of the present embodiment is the same as figure 2 basically the same.

[0061] The room temperature tensile strength of the high-strength and tough molybdenum alloy prepared in this embodiment is 1223 MPa, and the elongation is 8.2%.

Embodiment 3

[0063] This embodiment provides a high-strength and tough molybdenum alloy, which is made of the following raw materials in parts by weight: 20.0 g of titanium hydride, 2.0 g of zirconium hydride, 0.4 g of magnesium powder, and 1000 g of molybdenum powder.

[0064] The preparation method of the high-strength and toughness molybdenum alloy of this embodiment is basically the same as that of Embodiment 1.

[0065] The high-strength toughness molybdenum alloy tensile curve of the present embodiment and figure 1 Basically the same, the SEM photo of the high-strength and toughness molybdenum alloy of the present embodiment is the same as figure 2 basically the same.

[0066] The room temperature tensile strength of the high-strength and tough molybdenum alloy prepared in this embodiment is 1226 MPa, and the elongation is 8.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com