Fractional-order PID control design method based on phase margin and cutoff frequency

A technology of cut-off frequency and phase margin, which is applied to controllers with specific characteristics, electric controllers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

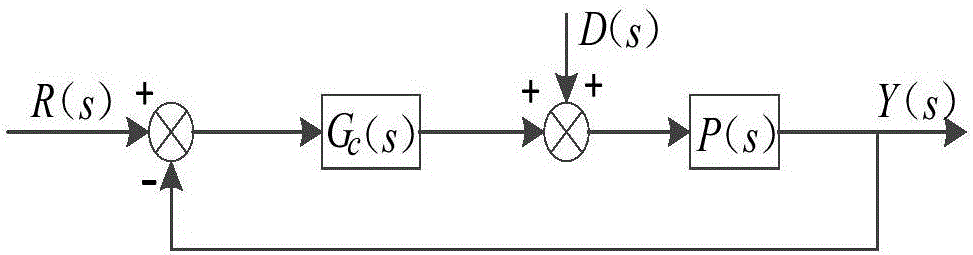

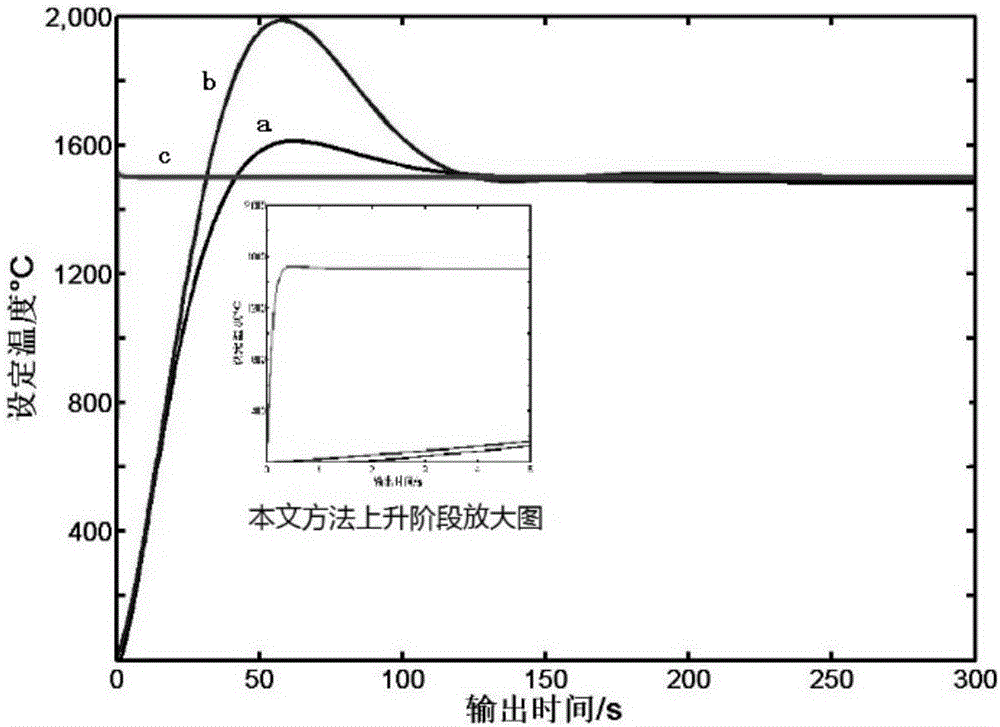

[0097] Aiming at the temperature control system of medium frequency induction furnace, this paper designs a fractional-order PID controller based on the principles of internal model control, fractional-order calculus, and PID control, and based on the phase margin φ of the control system m and the cutoff frequency ω c , to tune the controller parameters, this method can improve the dynamic performance of the control system while ensuring the robustness of the system.

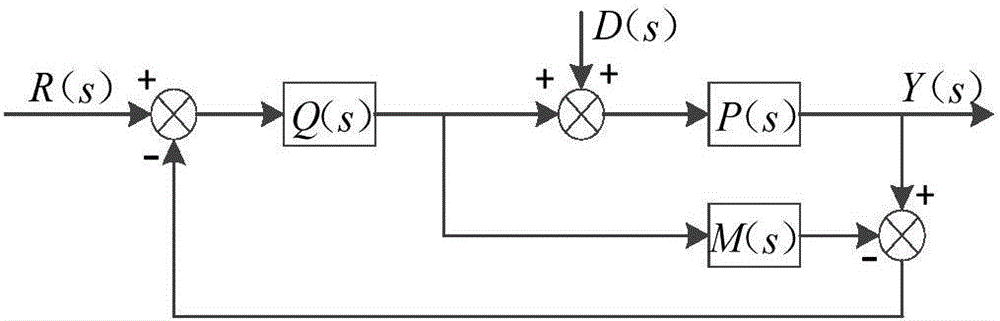

[0098] The design of the fractional order PID controller, the internal model control system structure diagram is as follows figure 1 As shown, where Q(s) is the internal model controller, P(s) is the controlled process, M(s) is the process model, D(s) is the disturbance, R(s) and Y(s) are the control system input and output.

[0099] First, the process model is decomposed into reversible and irreversible parts, where M + (s) is the irreversible part, M _ (s) is the reversible part, namely

[0100] M(s)=M +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com