Method for preparing clarified aftertaste-free purple sweet potato anthocyanin concentrated juice

A technology of purple sweet potato anthocyanin and concentrated juice, which is applied in the field of preparation of clarified purple sweet potato anthocyanin concentrated juice without aftertaste, can solve the problems of aftertaste, easy precipitation, high turbidity, etc., achieve low extraction temperature and shorten production The effect of period and strong flocculation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

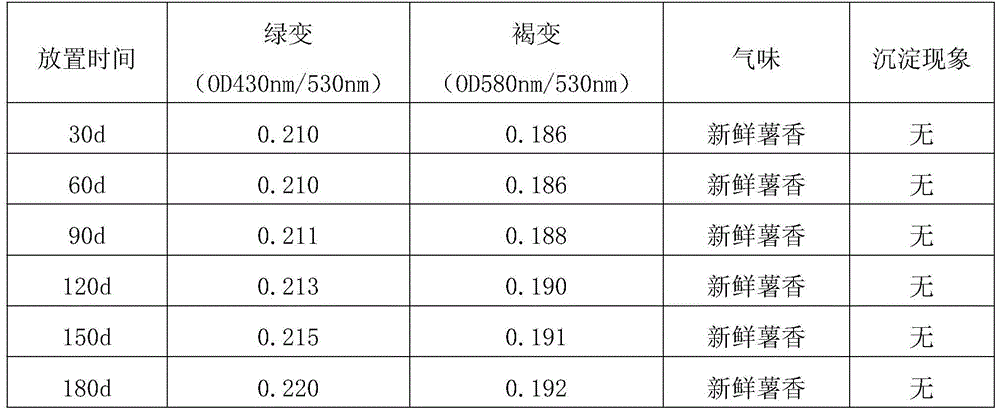

Examples

Embodiment 1

[0024] A preparation method of clarified and tasteless purple sweet potato anthocyanin concentrate juice includes the following steps:

[0025] (1) Preparation of crude purple sweet potato anthocyanin extract

[0026] Take 500g of purple sweet potato to remove the mud and wash, cut into 0.1-0.2cm thick slices, add 2.5 times the total mass of purple sweet potato, pH 3 citric acid aqueous solution, continue countercurrent extraction at 30 ℃ for 3 hours, then solid-liquid Separate to obtain a crude extract of purple sweet potato anthocyanin;

[0027] (2) Enzyme treatment to decompose macromolecular substances

[0028] Add 0.3% amylase and 0.6% cellulase of the total mass of the crude extract to the crude purple sweet potato anthocyanin extract, and fully react at 35°C for 1 hour to remove starch, cellulose and other macromolecular impurities. Stir every 15 minutes during this period; wherein the amylase and cellulase are acid-resistant enzymes, which can survive under the condition of p...

Embodiment 2

[0042] A preparation method of clarified and tasteless purple sweet potato anthocyanin concentrate juice includes the following steps:

[0043] (1) Preparation of crude purple sweet potato anthocyanin extract

[0044] Take 1000kg of purple sweet potato to remove the mud and wash, cut into 0.3-0.5cm size dice, add 4 times the total mass of purple sweet potato, pH 2.5 hydrochloric acid aqueous solution, continue countercurrent extraction at 20-40 ℃ for 6 hours, then solidify Liquid separation to obtain a crude extract of purple sweet potato anthocyanin;

[0045] (2) Enzyme treatment to decompose macromolecular substances

[0046] Add 0.6% amylase and 0.8% cellulase of the total mass of the crude extract to the crude purple sweet potato anthocyanin extract, and fully react at 40°C for 3 hours to remove starch, cellulose and other macromolecular impurities. Stir every 15 minutes during this period; wherein the amylase and cellulase are acid-resistant enzymes, which can survive under the ...

Embodiment 3

[0060] A preparation method of clarified and tasteless purple sweet potato anthocyanin concentrate juice includes the following steps:

[0061] (1) Preparation of crude purple sweet potato anthocyanin extract

[0062] Take 1500g purple sweet potato to remove the mud and wash, cut into 0.1-0.2cm thick slices, add 5 times the total mass of purple sweet potato, pH 5 citric acid aqueous solution, continue countercurrent extraction at 40 ℃ for 7 hours, then solid-liquid Separate to obtain a crude extract of purple sweet potato anthocyanin;

[0063] (2) Enzyme treatment to decompose macromolecular substances

[0064] Add 1.0% amylase and 0.3% cellulase of the total mass of the crude extract to the crude purple sweet potato anthocyanin extract, and fully react at 60°C for 4 hours to remove starch, cellulose and other macromolecular impurities. Stir every 20 minutes during this period; wherein the amylase and cellulase are acid-resistant enzymes, which can survive under the condition of pH 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com