Wire connecting and slitting machine for large-sized pole piece of lithium-ion battery

A lithium-ion battery and slitting machine technology, which is applied to the accessories of shearing machines, shearing machine equipment, shearing devices, etc., can solve the problems of powder drop, pole piece burr of single-piece die-cutting machine, etc., and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

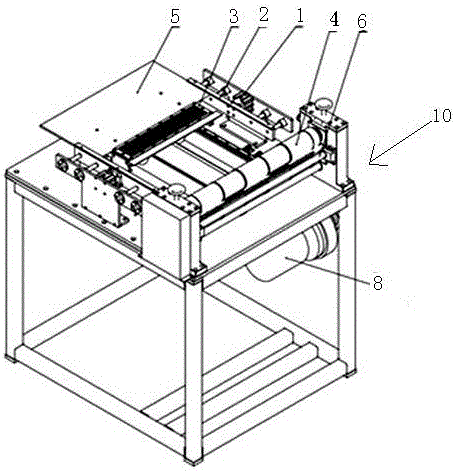

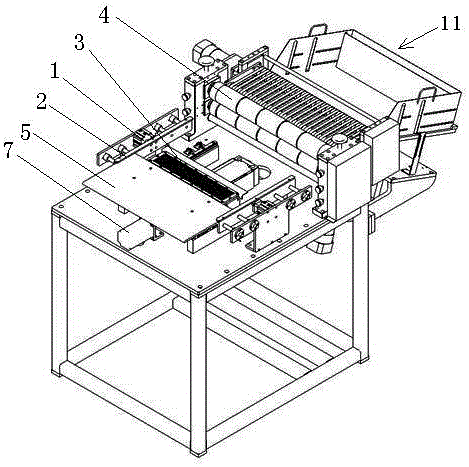

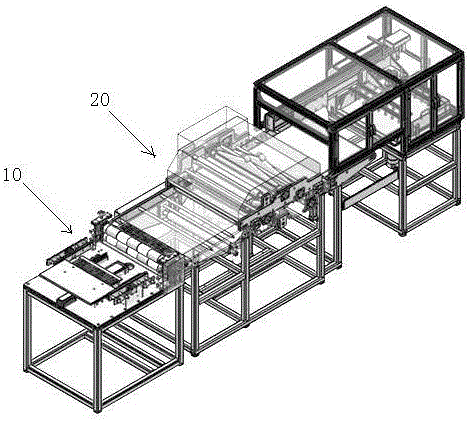

[0022] Please refer to figure 1 and figure 2 , Lithium-ion battery large-scale pole piece connecting line slitting machine, including frame, positioning panel 5, positioning power cylinder 1 is arranged on both sides, positioning pole piece pushing plate 2, and positioning panel 5 has an adsorption component 3 for absorbing and fixing the pole piece in front , the pole piece 30 forms a splint type positioning, the front side of the positioning panel 5 is provided with a pusher motor 7, the rear is provided with a hobbing head 4, the lower part of the hobbing head 4 is provided with a discharge roller 6, and the frame is provided with a roller. The cutting motor 8, the pushing motor 7 and the discharge roller 6 form a push-pull feeding, and the battery pole piece is formed by roll cutting.

[0023] The hobbing knife in the hobbing head 4 is ground and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com