Method for producing single PCS substrate by UV laser cutting

A technology of laser cutting and production methods, which is applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve problems such as hidden dangers in production quality, increase manual re-inspection, and affect normal delivery, so as to improve production capacity and Improve quality, improve equipment utilization, and avoid abnormal quality

Inactive Publication Date: 2017-01-25

江苏弘信华印电路科技有限公司

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] (1) After the cutting is completed, the substrate is scattered on the machine table and is not easy to take, which has hidden dangers to the production quality and low production efficiency;

[0004] (2) If the laser energy setting is too high, the finger is easy to oxidize, and if the energy is too low, the single PCS connecting rib is not easy to fall; the waste generated by the connecting rib not easy to fall will affect the production quality, and the production efficiency is low during the post-processing operation;

[0005] (3) There are too many equipment suctions in the hollowed-out area of the substrate, which is prone to offset during the cutting process, which increases manual re-inspection, increases production costs and cannot guarantee product quality, affecting normal delivery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0029] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

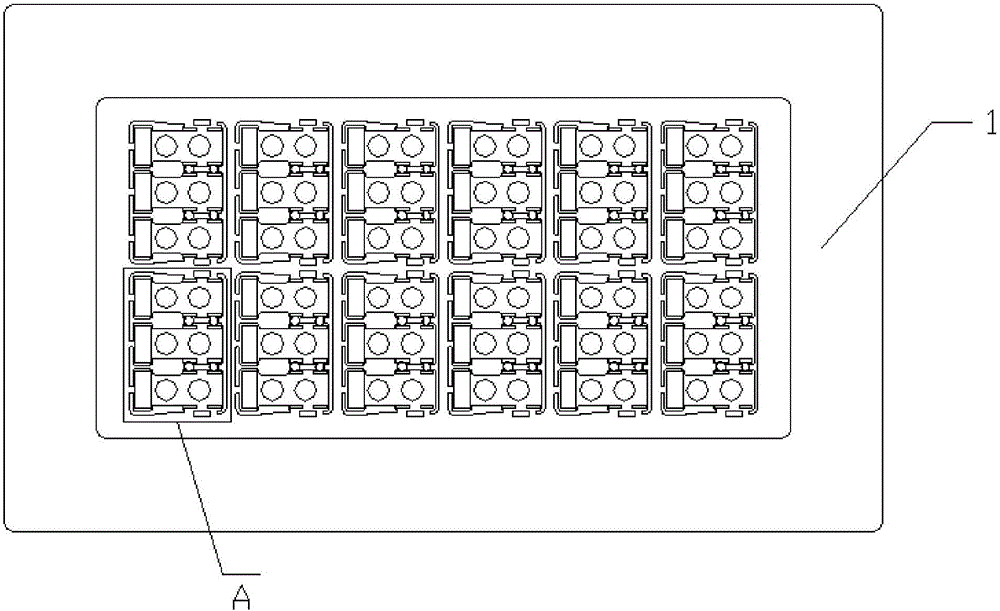

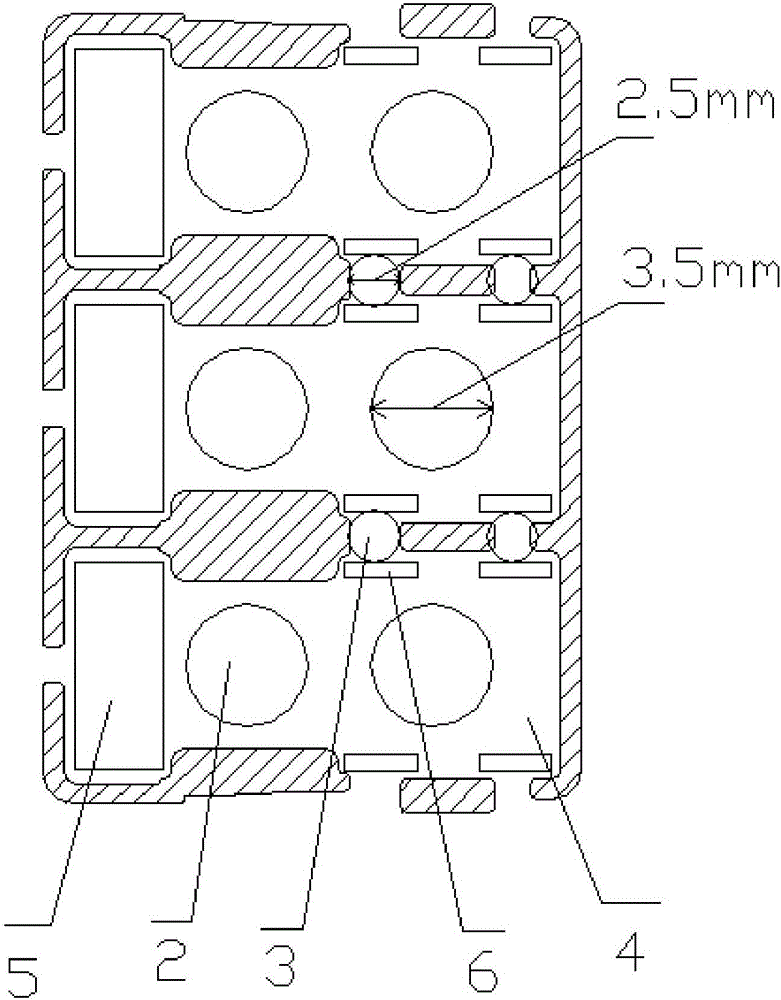

The invention relates to a method for producing a single PCS substrate by UV laser cutting. The method comprises the following steps: (1) selecting a specific fixture board basal plate; (2) drilling a first hole and a second hole in the fixture board basal plate; (3) performing primary depth-controlled milling in the fixture board basal plate to obtain a first milling groove; (4) performing secondary depth-controlled milling in the fixture board basal plate to obtain a second milling groove; (5) milling the periphery of the fixture board basal plate to obtain a fixture board finished product; (6) fixing a cut substrate on the fixture board, and positioning a single PCS substrate in the first milling groove and the second milling groove; (7) correcting the energy of UV laser equipment to position a cut substrate; and (8) performing UV laser treatment on the cut substrate to obtain a single PCS substrate, taking the substrate and placing. By adopting the method, the equipment utilization rate can be improved, the capacity and quality can be improved, and the cost can be reduced.

Description

technical field [0001] The invention relates to a production method of a substrate, in particular to a production method of cutting a single PCS substrate by UV laser. Background technique [0002] UV laser cutting is used for precise cutting of flexible circuit boards and organic cover films. The existing production method of UV laser cutting into single PCS has the following disadvantages: [0003] (1) After the cutting is completed, the substrate is scattered on the machine table and is not easy to take, which has hidden dangers to the production quality and low production efficiency; [0004] (2) If the laser energy setting is too high, the finger is easy to oxidize, and if the energy is too low, the single PCS connecting rib is not easy to fall; the waste generated by the connecting rib not easy to fall will affect the production quality, and the production efficiency is low during the post-processing operation; [0005] (3) There are too many equipment suctions in the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K26/38B23K26/70B23K37/04

CPCB23K26/38B23K26/702B23K37/0408

Inventor 杨凯

Owner 江苏弘信华印电路科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com