Equipment and method for taking out chain pin shaft

A chain and pin technology, applied in the field of chain maintenance, can solve the problems of reduced strength of pins and chain plates, failure to meet working strength requirements, changes in mechanical properties of chains, etc., to achieve rapid removal, increase labor productivity, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

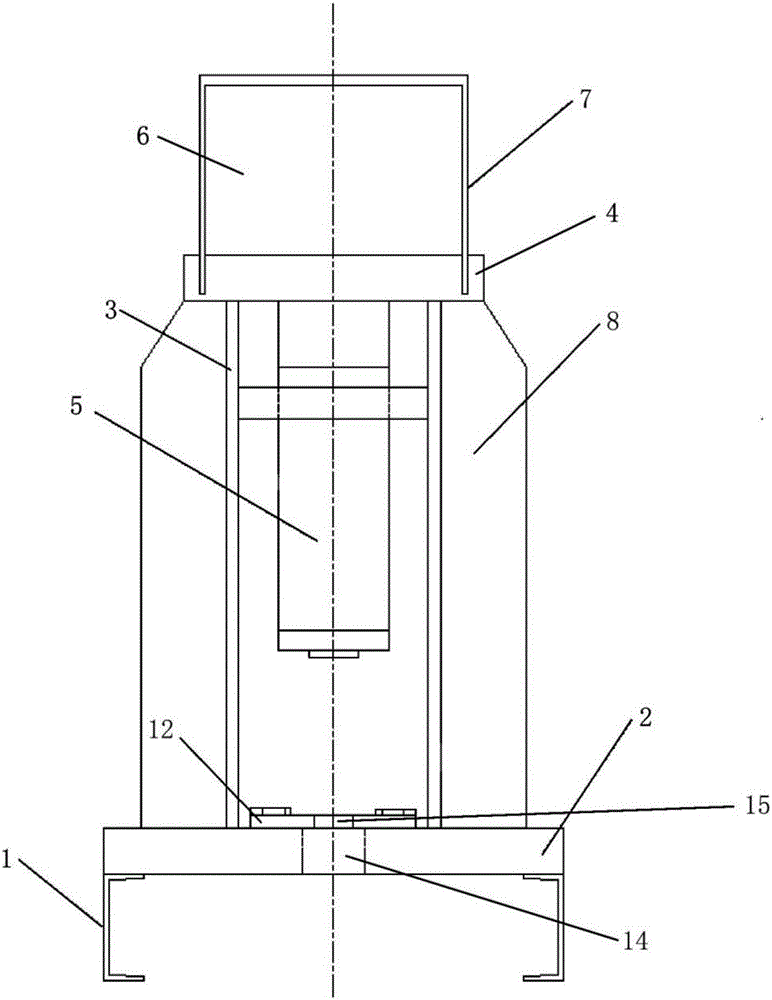

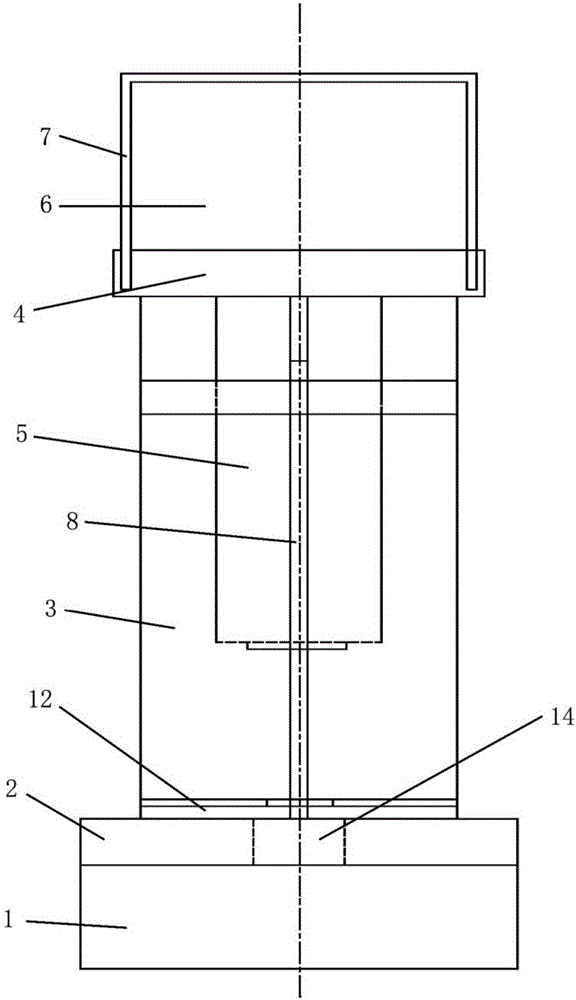

[0046] The overall size of the equipment for taking out the chain pin shaft is a vertical equipment with a length of 750mm, a width of 470mm, and a height of 1300mm.

[0047] Use a steel plate with a thickness of 70mm and the material is Q235 according to the design figure 1 and figure 2 Make the upper base plate 4 of the base frame and the lower base plate 2 of the base frame, use Q235 steel plate with a thickness of 20mm as the supporting connecting plate 3 on both sides, and vertically support the connecting plate 3, the upper base plate 4 of the base frame and the lower base plate 2 of the base frame Weld the reinforcing plate 8 to increase the strength. 200mm carbon channel steel is used as the base 1, and a gap of about 170mm is formed with the ground to facilitate cleaning of the pin shaft.

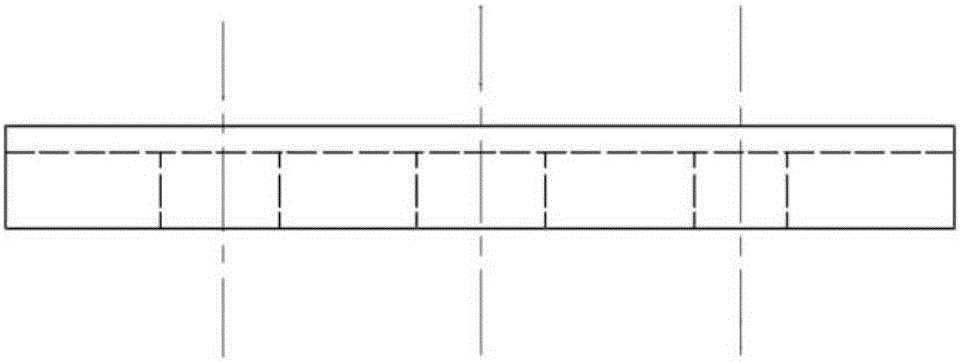

[0048] The bottom plate 4 of the base frame is a steel plate of 500mm*400mm*70mm, with 4 ring-shaped openings in the center. Round hole, used to fix the bottom of the hydrauli...

Embodiment 2

[0053] (1) Clean the oil on the chain to be repaired, and remove the upper check pin.

[0054] (2) Check that there is no oil leakage in the hydraulic system of the device, the system working pressure gauge, and the design limit pressure gauge (30Mpa) ensure that the system is normal.

[0055] (3) According to the size of the chain, select the appropriate movable bottom plate mold and the corresponding aperture and install it.

[0056] (4) Put the chain on the movable bottom plate, and the pin shaft is facing the pin shaft hole of the movable bottom plate.

[0057] (5) Use the guide rod (diameter smaller than the chain pin shaft 20 ~ 25mm) to resist, start the hydraulic system, the hydraulic cylinder pressure head is slowly pressed down, so that the guide rod bears the pre-tightening force, then suspend the pressure of the hydraulic system, and fine-tune the guide rod And chain, the pin shaft of chain is perpendicular to base plate, and the center of circle of guide bar is ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com