Explosive-proof cabin crane capable of centrally and fixedly arranging driving device at end part

A driving device, translational driving device technology, applied in safety devices, lifting equipment in mines, walking mechanisms, etc., can solve the problems of high price, large size, limited height of ship engine room, etc., achieve large lifting net height, increase The effect of cabin storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

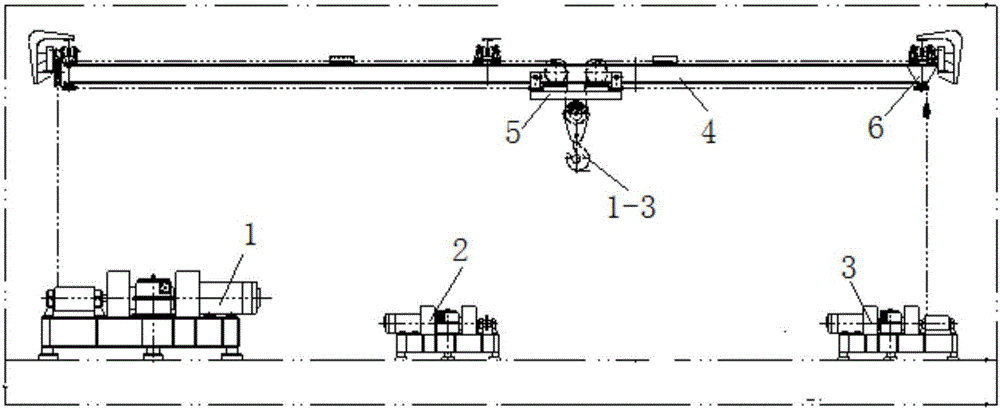

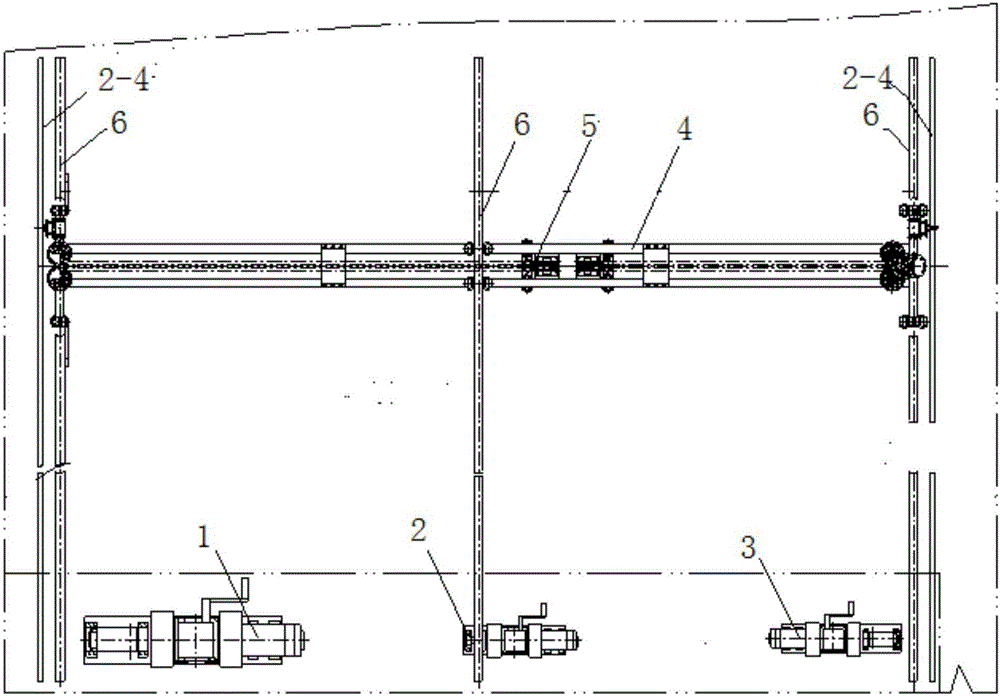

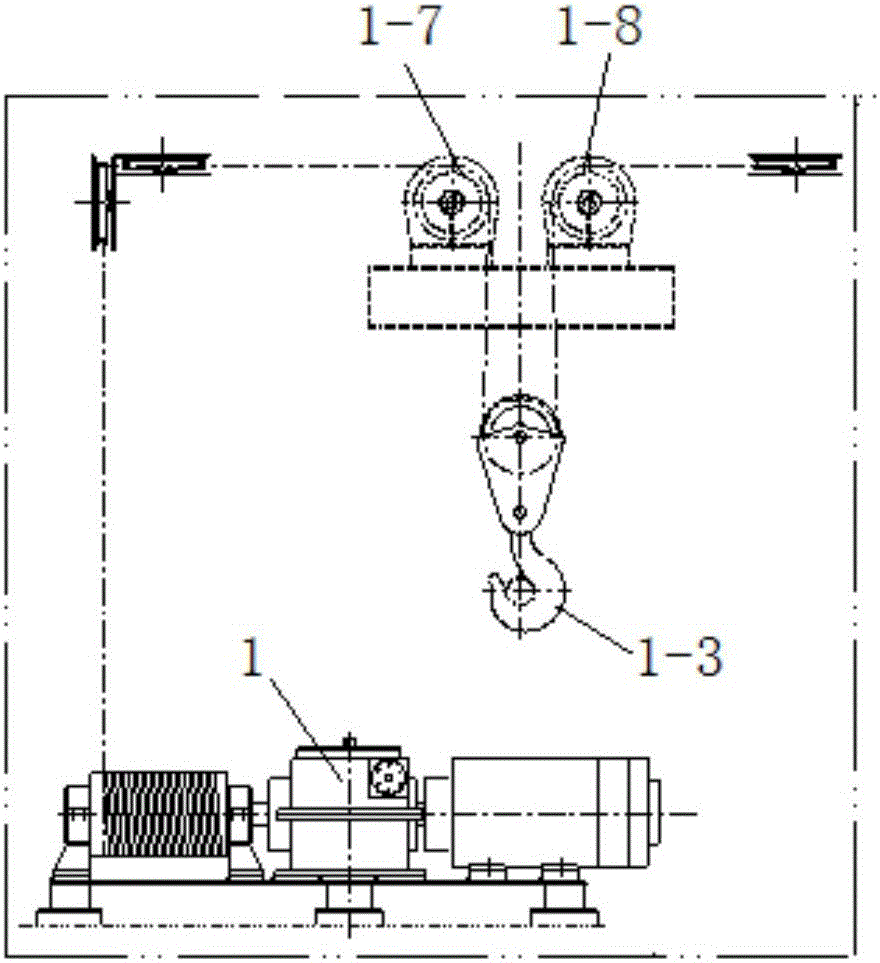

[0022] Such as figure 1 , As shown in 2, the driving device of the present invention is centralized and fixedly arranged at the end of the explosion-proof nacelle crane, which is mainly composed of the lifting and lowering driving device 1, the longitudinal translation driving device 2, the transverse translation driving device 3, the double beam bridge 4, and the translation trolley 5. , Orbit 6 and other components.

[0023] Three rails 6 are installed under the roof of the nacelle and arranged longitudinally. Two rails 6 are on both sides of the nacelle, and one rail 6 is in the middle of the cabin. The double-beam bridge 4 is movably connected to the three rails 6 through a pulley block. The double-beam bridge 4 is equipped with a translation trolley 5, the upper and lower sides of the nacelle are respectively equipped with a lifting and lowering drive device 1, a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com