Heat pump evaporation system and heat pump evaporation method used for processing low-activity liquid waste in nuclear plant

A heat pump evaporation, nuclear power plant technology, applied in heating water/sewage treatment and other directions, can solve the problems of reduced heat exchange efficiency of heat exchangers, inability to meet energy saving and emission standards, low decontamination efficiency, etc., to reduce system energy consumption. , High economic efficiency and application prospects, the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

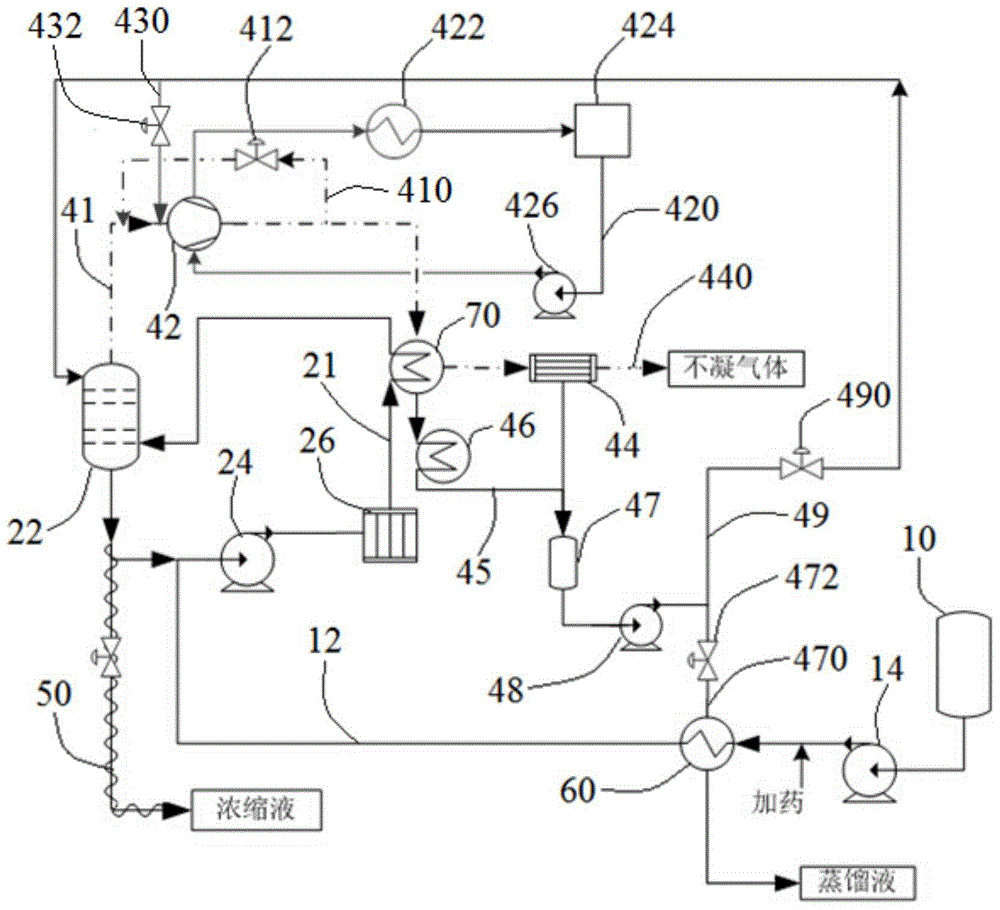

[0030] see figure 1 , the heat pump evaporation system used to treat low-level waste liquid from nuclear power plants in the present invention includes a waste liquid feed pipeline, an evaporation tower reactor circulation loop, a steam disposal pipeline, a concentrated liquid discharge pipeline, a regenerative heat exchanger 60 and an evaporation tower Heat exchanger 70. Wherein, the regenerative heat exchanger 60 is connected between the waste liquid feed pipeline and the steam disposal pipeline, and the evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com