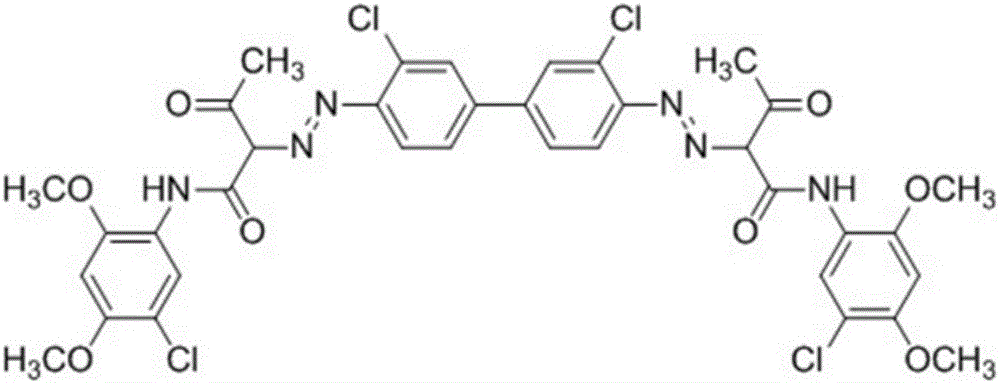

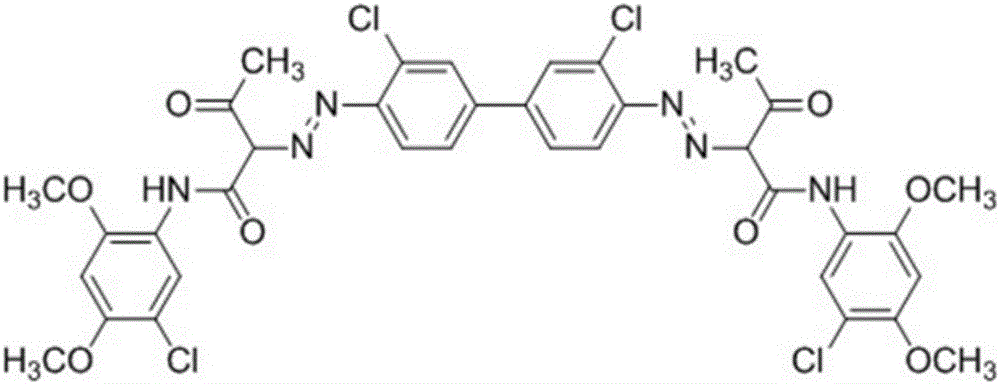

Yellow bisazo pigment and preparation method

A disazo and pigment technology, applied in the field of disazo pigments, can solve problems such as price fluctuations, large contradictions between market supply and demand, and cost pressures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of yellow disazo pigment according to claim 1, carries out according to the following steps:

[0027] (1), prepare diazonium salt solution:

[0028] Add 20 parts by weight of 3,3'-dichlorobenzidine hydrochloride and 45 parts by weight of hydrochloric acid to 200 parts by weight of water for beating for 30 minutes, then quickly add 35 parts by weight of sodium nitrite for diazotization, Stir for 45 minutes, add a nitrite-removing substance to remove excess nitrous acid, stir for 15 minutes, add an adsorbent, and filter to obtain a diazonium salt solution;

[0029] (2), preparation of coupling solution:

[0030] Add 60 parts by weight of 2,4-dimethoxy-5-chloroacetoacetanilide to 150 parts by weight of water, and then add 25 parts by weight of an alkaline solution to dissolve 2,4-dimethoxy-5- Chloroacetoacetanilide was dissolved and stirred for 0.5 hour to obtain a clear coupling solution;

[0031] (3) Add 20 parts by mass of w...

Embodiment 2

[0042] Embodiment 2: a kind of preparation method of yellow disazo pigment according to claim 1, carries out according to the following steps:

[0043] (1), prepare diazonium salt solution:

[0044] Add 50 parts by weight of 3,3'-dichlorobenzidine hydrochloride and 100 parts by weight of hydrochloric acid to 300 parts by weight of water for beating for 60 minutes, then quickly add 70 parts by weight of sodium nitrite for diazotization, Stir for 70 minutes, add a nitrite-removing substance to remove excess nitrous acid, stir for 15 minutes, add an adsorbent, and filter to obtain a diazonium salt solution;

[0045] (2), preparation of coupling solution:

[0046] Add 80 parts by weight of 2,4-dimethoxy-5-chloroacetoacetanilide to 200 parts by weight of water, and then add 40 parts by weight of an alkaline solution to dissolve 2,4-dimethoxy-5- Chloroacetoacetanilide was dissolved and stirred for 0.8 hours to obtain a clear coupling solution;

[0047] (3) Add 70 parts by mass of w...

Embodiment 3

[0058] Embodiment 3: a kind of preparation method of yellow disazo pigment according to claim 1, carries out according to the following steps:

[0059] (1), prepare diazonium salt solution:

[0060] Add 80 parts by weight of 3,3'-dichlorobenzidine hydrochloride and 120 parts by weight of hydrochloric acid to 350 parts by weight of water for beating for 90 minutes, then quickly add 100 parts by weight of sodium nitrite for diazotization, Stir for 90 minutes, add a nitrite-removing substance to remove excess nitrous acid, stir for 15 minutes, add an adsorbent, and filter to obtain a diazonium salt solution;

[0061] (2), preparation of coupling solution:

[0062] Add 120 parts by weight of 2,4-dimethoxy-5-chloroacetoacetanilide to 300 parts by weight of water, and then add 65 parts by weight of an alkaline solution to dissolve 2,4-dimethoxy-5- Chloroacetoacetanilide was dissolved and stirred for ~1 hour to obtain a clear coupling solution;

[0063] (3) Add 100 parts by mass o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com