Pneumatic explosive charging spray head for upward medium-length hole

A charging and pneumatic technology, applied in the direction of blasting, etc., can solve the problems of affecting the blasting effect, forming voids, and uneven distribution of explosives, so as to avoid uneven distribution of explosives, reduce the impact force, and reduce powder return of charge rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

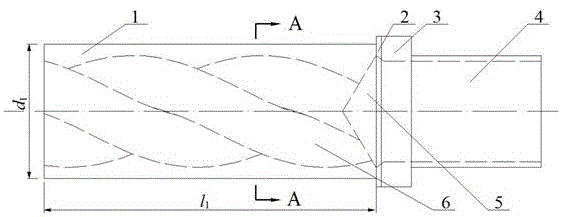

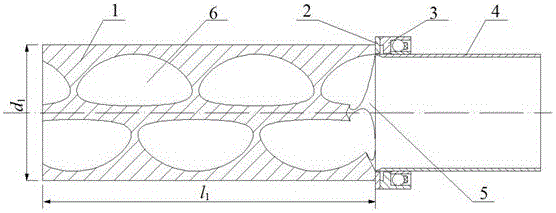

[0024] The utility model relates to a pneumatic charge spraying head used for upward-to-medium-deep holes. like Figure 1 to Figure 4 As shown, the pneumatic charge spray head is composed of a rotor 1 , a bearing connecting ring 2 , a bearing 3 and an interface 4 . The right end of the rotor 1 is connected to the inner ring screw hole 7 of the bearing connecting ring 2 by screws, the left side of the outer ring of the bearing 3 is connected to the outer ring screw hole 8 of the bearing connecting ring 2 by screws, and the bearing 3 is installed on the left end of the interface 4 .

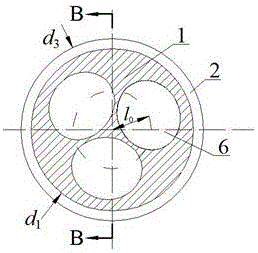

[0025] like Figure 1 to Figure 3 As shown, the outer shape of the rotor 1 is cylindrical, and the rotor 1 is provided with three channels 6. The cross-sections of the three channels 6 are respectively circular, and the diameters of the three channels 6 are d. 2 Both are 0.35~0.37d 0 , d 0 is the diameter of the charging hole. The three channels 6 are distributed in a twist shape with the axis...

Embodiment 2

[0032] The utility model relates to a pneumatic charge spraying head used for upward-to-medium-deep holes. Except the following technical parameters, all the other are the same as in Example 1:

[0033] The diameter d of the three channels 6 shown 2 Both are 0.36~0.38d 0 ;

[0034] The distance l between any point of the cylindrical helix and the axis of the rotor 1 0 =0.21~0.22d 0 , the lead of the cylindrical helix S=1.6~1.8d 0 ;

[0035] The length l of the rotor 1 1 =90~100mm, the outer diameter d of rotor 1 1 =0.82~0.85d 0 .

[0036] Compared with the prior art, this specific embodiment has the following positive effects:

[0037]This specific embodiment is composed of a rotor 1, a bearing connecting ring 2, a bearing 3 and an interface 4; the right end of the rotor 1 is connected to the inner ring screw hole 7 of the bearing connecting ring 2 through screws, and the left end of the outer ring of the bearing 3 is connected to the bearing connecting ring through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com