Friction abrasion testing machine

A friction and wear test and test device technology, applied in the direction of testing wear resistance, etc., can solve the problems of complex friction and wear research, waste of robot force, material resources and financial resources, etc., to shorten the test period, reduce the test cost, and enrich the test forms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

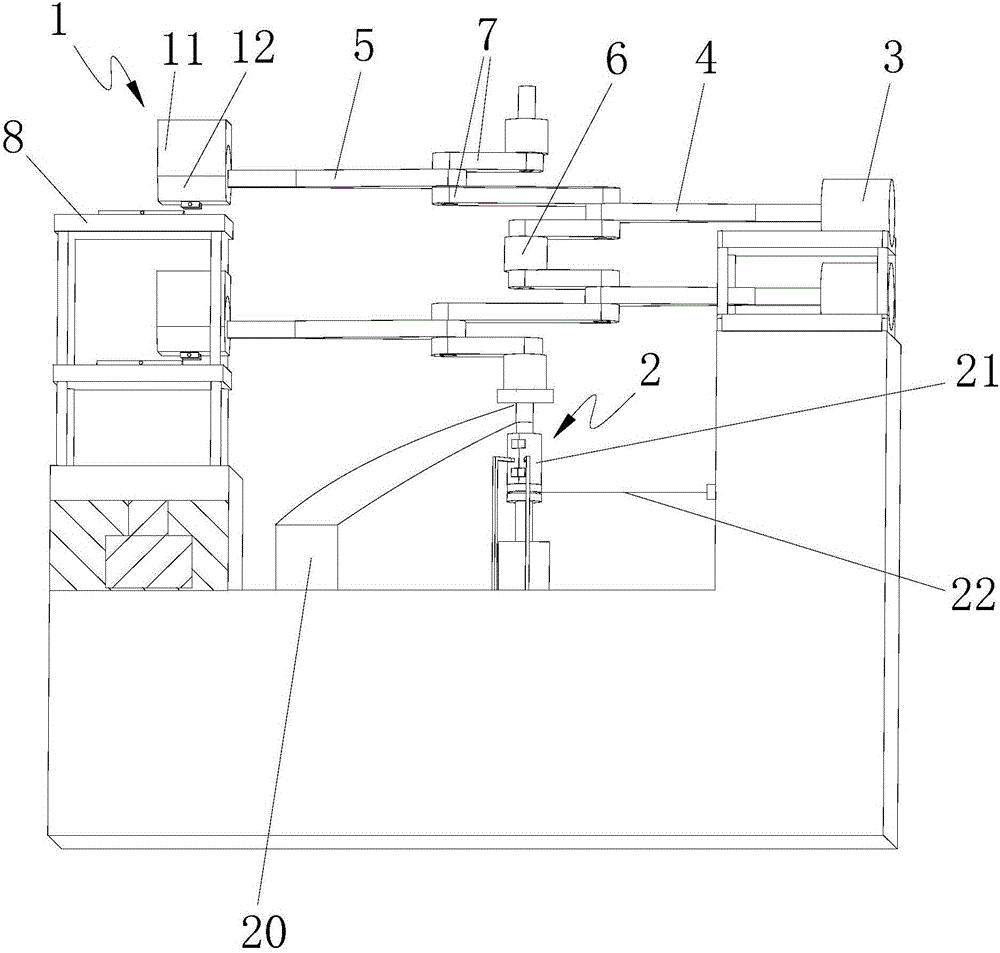

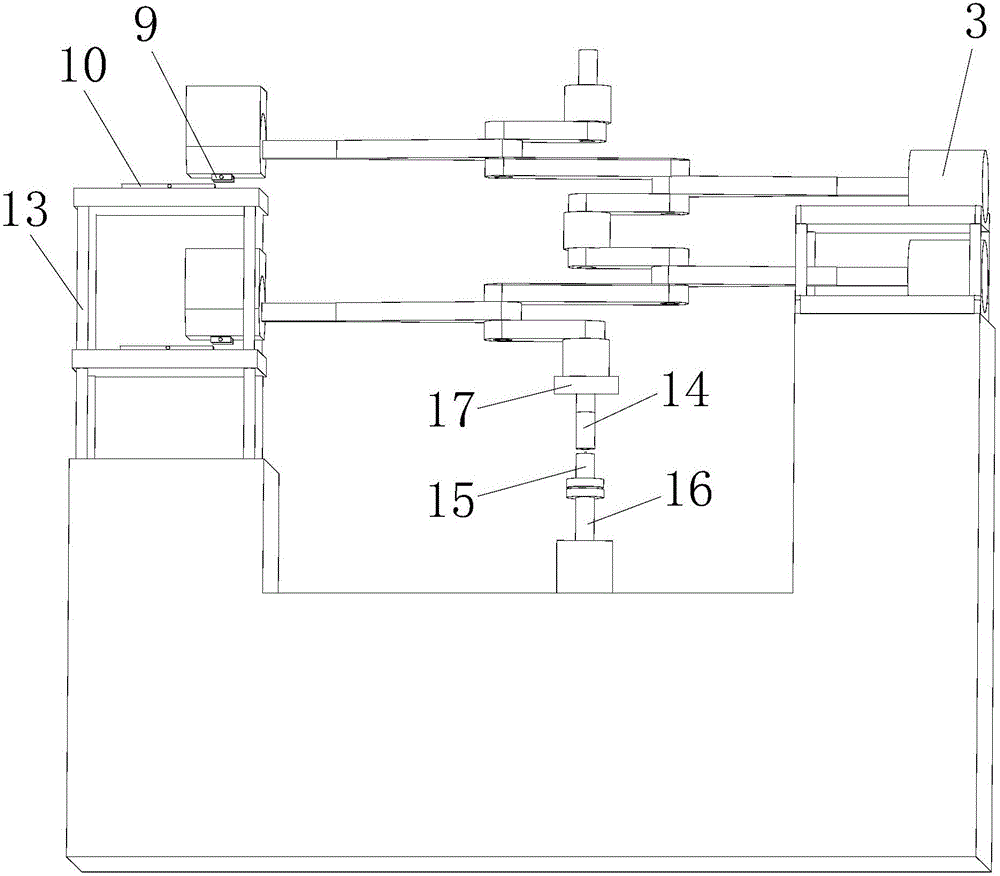

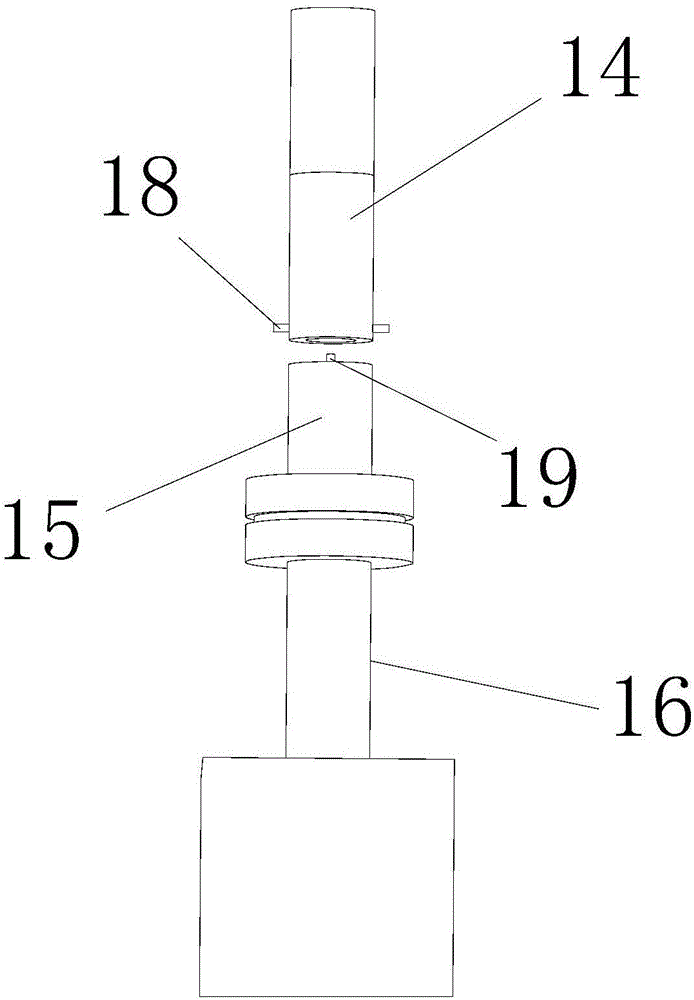

[0023] A friction and wear testing machine, comprising a sliding friction test device 1, a rotary friction test device 2 and a power mechanism that provides power to the sliding friction test device and the rotary friction test device, the power mechanism includes a cylinder 3, a crankshaft, a drive connecting rod 4 and a diameter To the output connecting rod 5, the crankshaft has a connecting rod 7 and an axially staggered main journal 6, a first connecting rod journal axis, and a second connecting rod journal axis. The main journal is located on the main axis of the crankshaft, and the first connecting rod journal axis and The second connecting rod journal is located on both sides of the main axis of the crankshaft. The main journal, the first connecting rod journal and the second connecting rod journal are respectively connected by connecting rods. One end of the driving connecting rod is hinged to the cylinder, and the other end is connected to the second connecting rod. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com