MOEMS (micro optical electronic mechanical system) laser scanning micromirror array speckle suppression device

A scanning micromirror and suppression device technology, applied in optics, optical components, instruments, etc., can solve the problems of cumbersome operation process, large volume structure, complex structure, etc., and achieve the effect of convenient operation, small volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

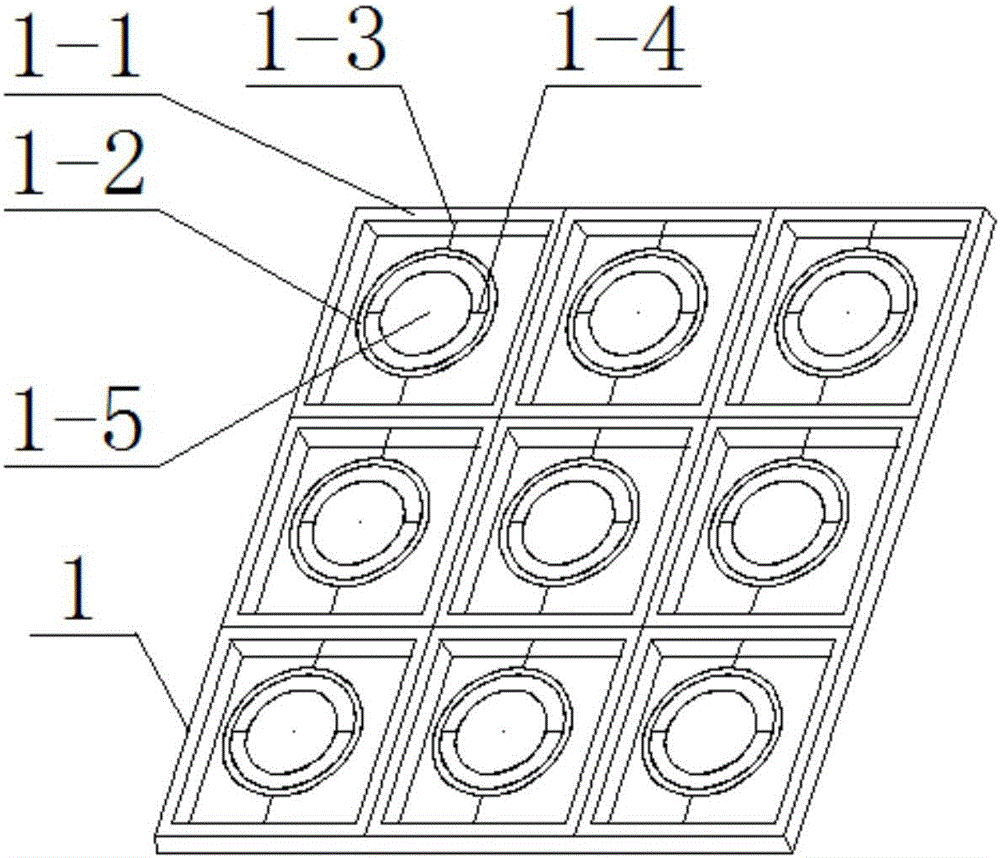

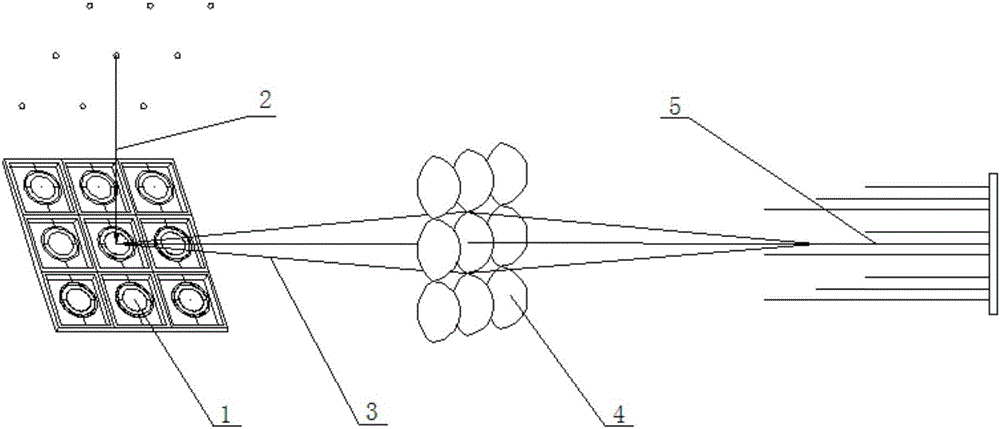

[0021] A MOEMS laser scanning micromirror array speckle suppression device is composed of 3×3 scanning micromirrors 1, and a single scanning micromirror consists of a fixed anchor point 1-1 rotating along the X axis and a fixed anchor point 1-1 rotating along the Y axis 2. The torsion beam 1-3 rotating along the X axis, the torsion beam 1-4 rotating along the Y axis and the mirror surface 1-5 are composed. The torsion beam 1-3 rotating along the X axis is connected to the Between the rotating fixed anchor point 1-1 and the fixed anchor point 1-2 rotating along the Y axis, the torsion beam 1-4 rotating along the Y axis is connected to the fixed anchor point 1-2 rotating along the Y axis Between the mirror surface 1-5; under the drive of electromagnetic force or electrostatic force, etc., synchronously control all scanning micromirrors to realize scanning in X and Y directions; or independently control a single scanning micromirror to realize scanning in X and Y directions ; The...

Embodiment 2

[0023] A MOEMS laser scanning micromirror array speckle suppression device is composed of 1×3 scanning micromirrors 1, and a single scanning micromirror consists of a fixed anchor point 1-1 rotating along the X axis and a fixed anchor point 1-1 rotating along the Y axis 2. The torsion beam 1-3 rotating along the X axis, the torsion beam 1-4 rotating along the Y axis and the mirror surface 1-5 are composed. The torsion beam 1-3 rotating along the X axis is connected to the Between the rotating fixed anchor point 1-1 and the fixed anchor point 1-2 rotating along the Y axis, the torsion beam 1-4 rotating along the Y axis is connected to the fixed anchor point 1-2 rotating along the Y axis Between the mirror surface 1-5; under the drive of electromagnetic force or electrostatic force, etc., synchronously control all scanning micromirrors to realize scanning in X and Y directions; or independently control a single scanning micromirror to realize scanning in X and Y directions ; The...

Embodiment 3

[0025] A MOEMS laser scanning micromirror array speckle suppression device is composed of 2×3 scanning micromirrors 1, and a single scanning micromirror consists of a fixed anchor point 1-1 rotating along the X axis and a fixed anchor point 1-1 rotating along the Y axis 2. The torsion beam 1-3 rotating along the X axis, the torsion beam 1-4 rotating along the Y axis and the mirror surface 1-5 are composed. The torsion beam 1-3 rotating along the X axis is connected to the Between the rotating fixed anchor point 1-1 and the fixed anchor point 1-2 rotating along the Y axis, the torsion beam 1-4 rotating along the Y axis is connected to the fixed anchor point 1-2 rotating along the Y axis Between the mirror surface 1-5; under the drive of electromagnetic force or electrostatic force, etc., synchronously control all scanning micromirrors to realize scanning in X and Y directions; or independently control a single scanning micromirror to realize scanning in X and Y directions ; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com