Cross-linking type polybenzimidazole/silicon dioxide high-temperature proton exchange membrane with high oxidation resistance and preparation method thereof

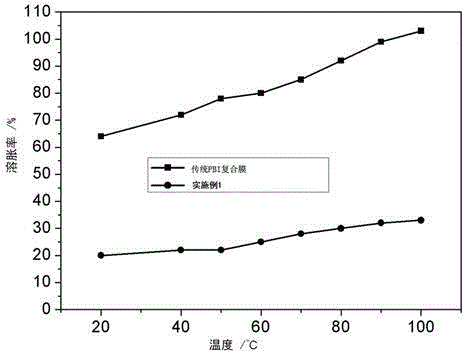

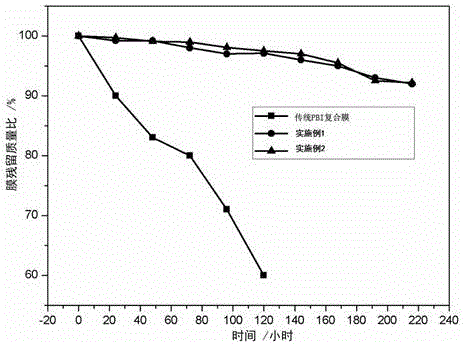

A polybenzimidazole and proton exchange membrane technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of battery performance degradation and aggravated PBI membrane degradation, so as to reduce swelling problems and improve oxidation resistance , Improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a cross-linked polybenzimidazole / silicon dioxide high-temperature proton exchange membrane with high oxidation resistance, comprising the following steps:

[0035] (1) Dissolve 5 g PBI in 500 g NMP, stir for 12 hours, and filter twice to remove impurities; then add 5 g CeO 2 , ultrasonic for 30 minutes, to obtain the casting liquid;

[0036] (2) Pour the casting liquid obtained in step (1) into the cast film plate, and then place it in a constant temperature and humidity box with a humidity of 55% (humidity) and a temperature of 80°C for 6 hours to carry out gas phase transformation, and then immerse in NMP Take it out after 1 hour in the aqueous solution, and dry it in vacuum at 100°C for 10 hours to obtain a porous inner layer with a thickness of 60 microns; wherein, the NMP aqueous solution is obtained by mixing NMP and deionized water at a volume ratio of 1:1;

[0037] (3) Dissolve 0.5 g PBI in 10 g NMP, stir for 12 hours, and filter twice to...

Embodiment 2

[0044] A method for preparing a cross-linked polybenzimidazole / silicon dioxide high-temperature proton exchange membrane with high oxidation resistance, comprising the following steps:

[0045] (1) Dissolve 3 g PBI in 100 g NMP, stir for 12 hours, and filter twice to remove impurities; then add 0.5 g MnO 2 , ultrasonic for 30 minutes, to obtain the casting liquid;

[0046] (2) Pour the casting liquid obtained in step (1) into the casting film plate, and then place it in a constant temperature and humidity box with a humidity of 65% (humidity) and a temperature of 70°C for 8 hours to carry out gas phase transformation, and then immerse in NMP Take it out after 2 hours in the aqueous solution, and dry it in vacuum at 100°C for 10 hours to obtain a porous inner layer with a thickness of 70 microns; wherein, the NMP aqueous solution is obtained by mixing NMP and deionized water at a volume ratio of 1:1;

[0047] (3) Dissolve 0.3 g PBI in 10 g NMP, stir for 12 hours, and filter tw...

Embodiment 3

[0054] A method for preparing a cross-linked polybenzimidazole / silicon dioxide high-temperature proton exchange membrane with high oxidation resistance, comprising the following steps:

[0055] (1) Dissolve 2 g of PBI in 1000 g of NMP, stir for 12 hours, and filter twice to remove impurities; then add 0.5 g of modified composite powder, and ultrasonicate for 30 minutes to obtain a casting solution;

[0056] (2) Inject the casting liquid obtained in step (1) into the cast film plate, and then place it in a constant temperature and humidity box with a humidity of 65% (humidity) and a temperature of 70°C for 0.5 hours to perform gas phase transformation, and then immerse in NMP Take it out after 3 hours in the aqueous solution, and dry it in vacuum at 100°C for 10 hours to obtain a porous inner layer with a thickness of 80 microns; wherein, the NMP aqueous solution is obtained by mixing NMP and deionized water at a volume ratio of 2:1;

[0057] (3) Dissolve 0.1 g PBI in 10 g NMP,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com