Charging station charging system for super-capacitor vehicle and control method

A charging system and charging station technology, applied in electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of wasting passenger time, long parking and charging time, and prolonging operation time, and achieve the effect of avoiding arcing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

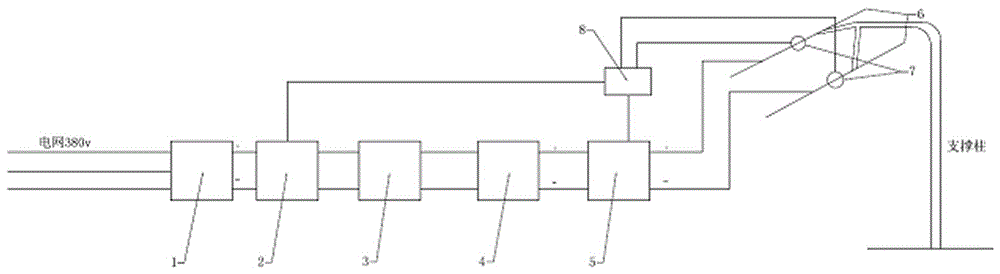

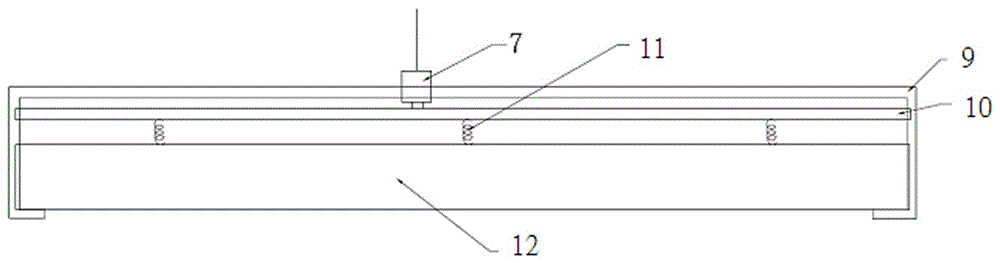

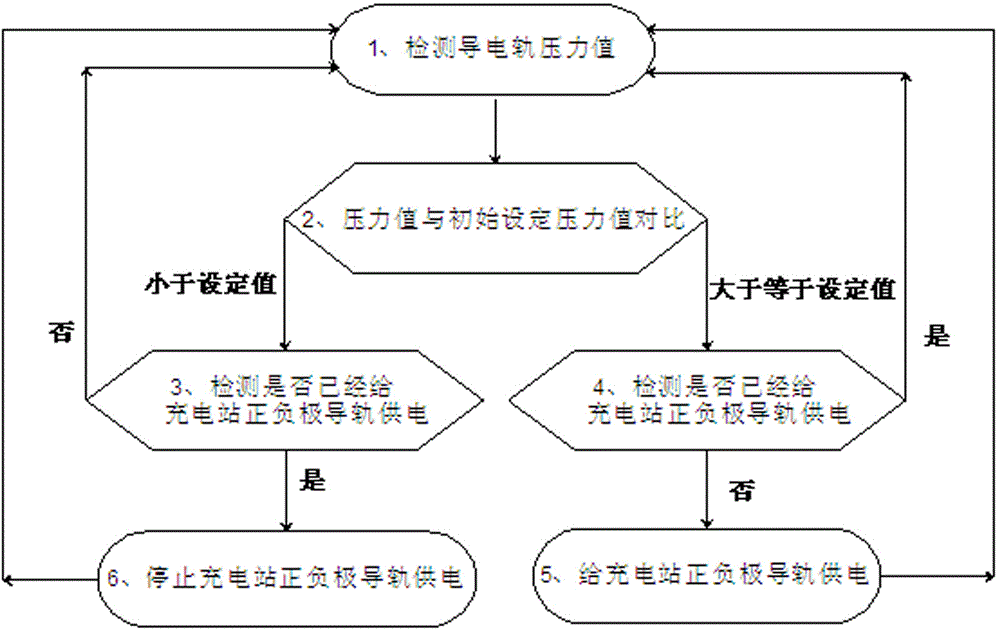

[0022] Refer to attached figure 1 , a supercapacitor vehicle charging station charging system, which includes: a controller 8, a rectifier module 1 connected to the grid, a high-frequency converter module 2 connected to the rectifier module 1, and a high-frequency converter module 2 connected The high-frequency transformer module 3, the DC circuit breaker 5 connected to the high-frequency transformer module 3, the positive and negative guide rails 6 of the charging station connected to the DC circuit breaker 5, and the positive and negative guide rails installed on the charging station respectively The two pressure sensors 7 on the top are respectively used to detect the contact pressure between the pantograph of the supercapacitor vehicle and the positive and negative guide rails of the charging station, and the controller 8 compares the pressure value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com