Cold trap microwave vacuum drying device

A technology of microwave vacuum drying and cold trap, which is applied in application, food processing, food science, etc., can solve problems such as low efficiency and poor drying effect of materials, and achieve the effects of improving quality, prolonging drying time, and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

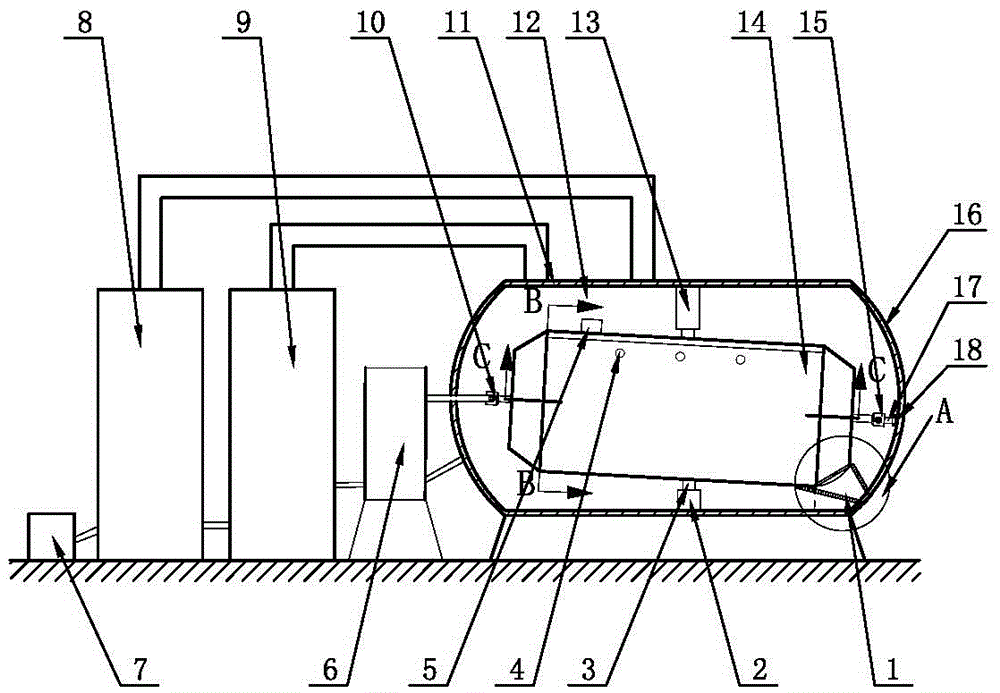

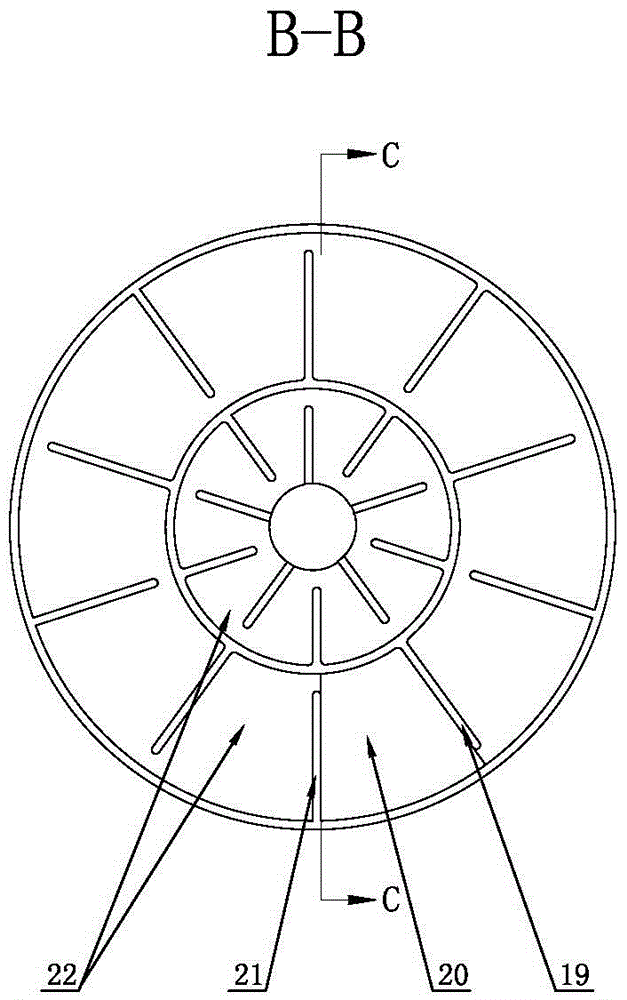

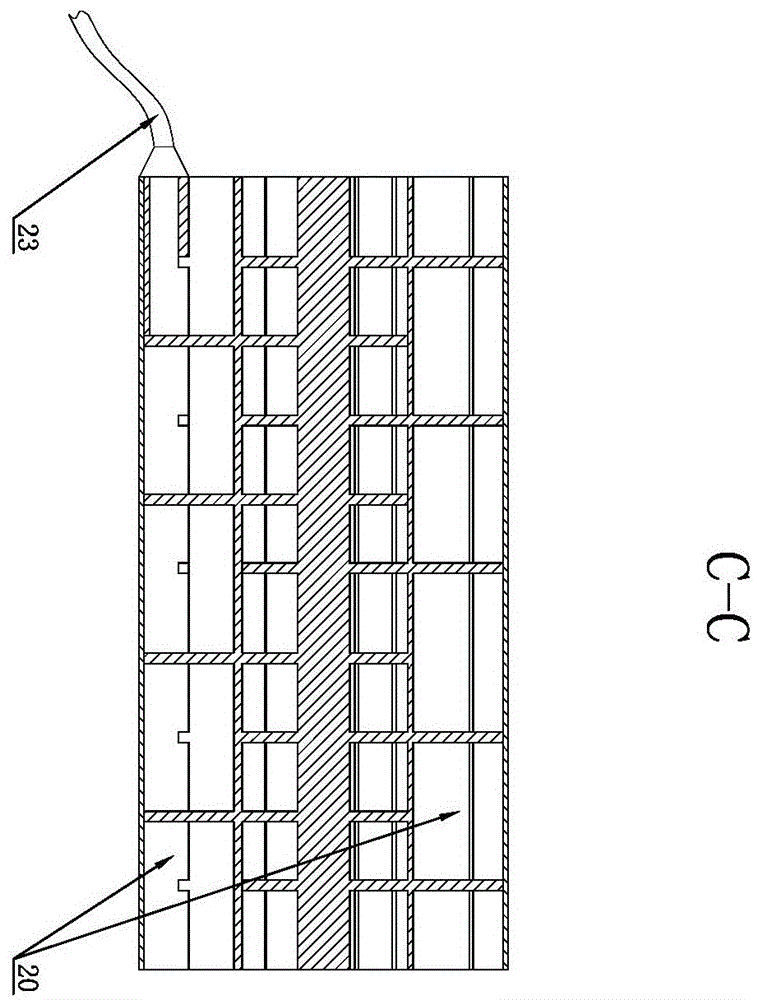

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-7The shown cold-trap microwave vacuum drying device includes a motor 6, a cold-trap device 9, a vacuum pump 8 and a tank body 11 with a housing cavity 12, the vacuum pump 8 and the cold-trap device 9 are connected to the tank body 11, and the two ends of the tank body 11 The tank cover 16 is installed, the tank body 11 is provided with a rotatable material tank 14, the material tank 14 is provided with a cavity for placing materials, and the inner wall of the tank body 11 is provided with a microwave generator 25 for heating the material tank 14, The feed port and the discharge port of the material tank 14 are respectively at the two ends of the material tank 14, and the material is discharged out of the tank body 11 through the discharge port of the material tank 14, and a number of vent holes 4 are arranged on the material tank 14; The 14th ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com