Enhanced denitrification reactor used for advanced denitrification and advanced denitrification method of reactor

A deep denitrification and reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of short process automation, large floor area, troublesome management, etc., to achieve Increased residence time, high degree of automation, and short process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

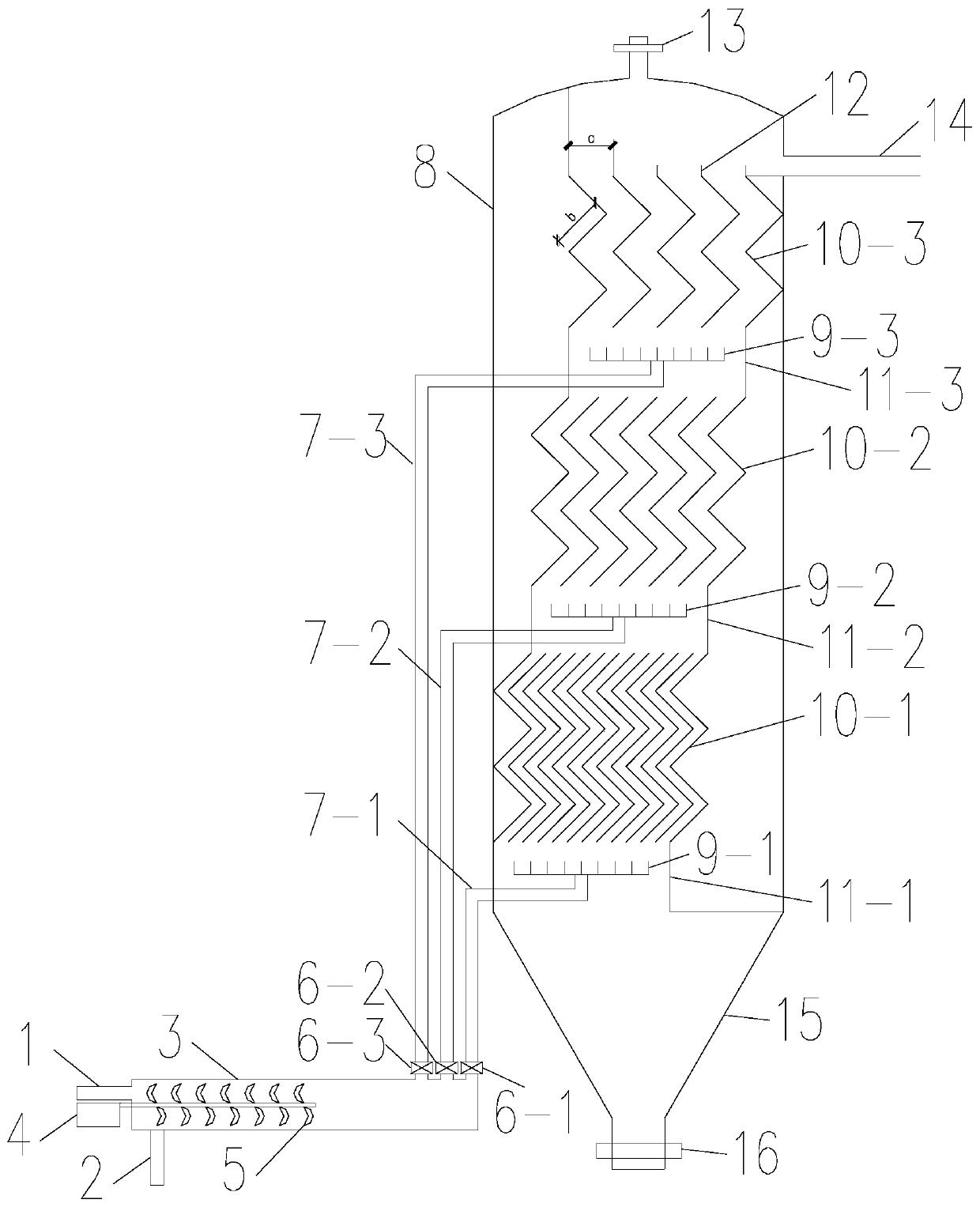

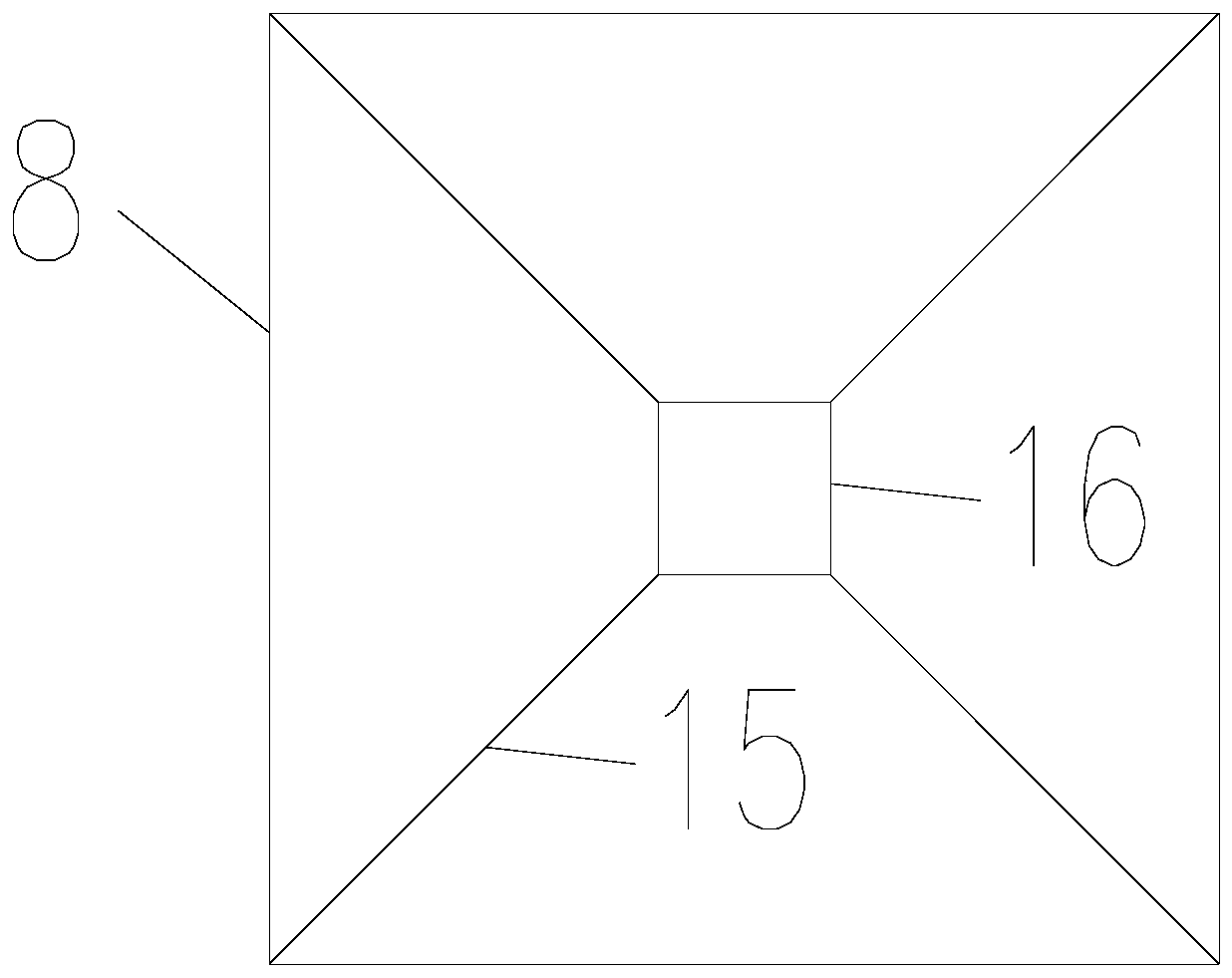

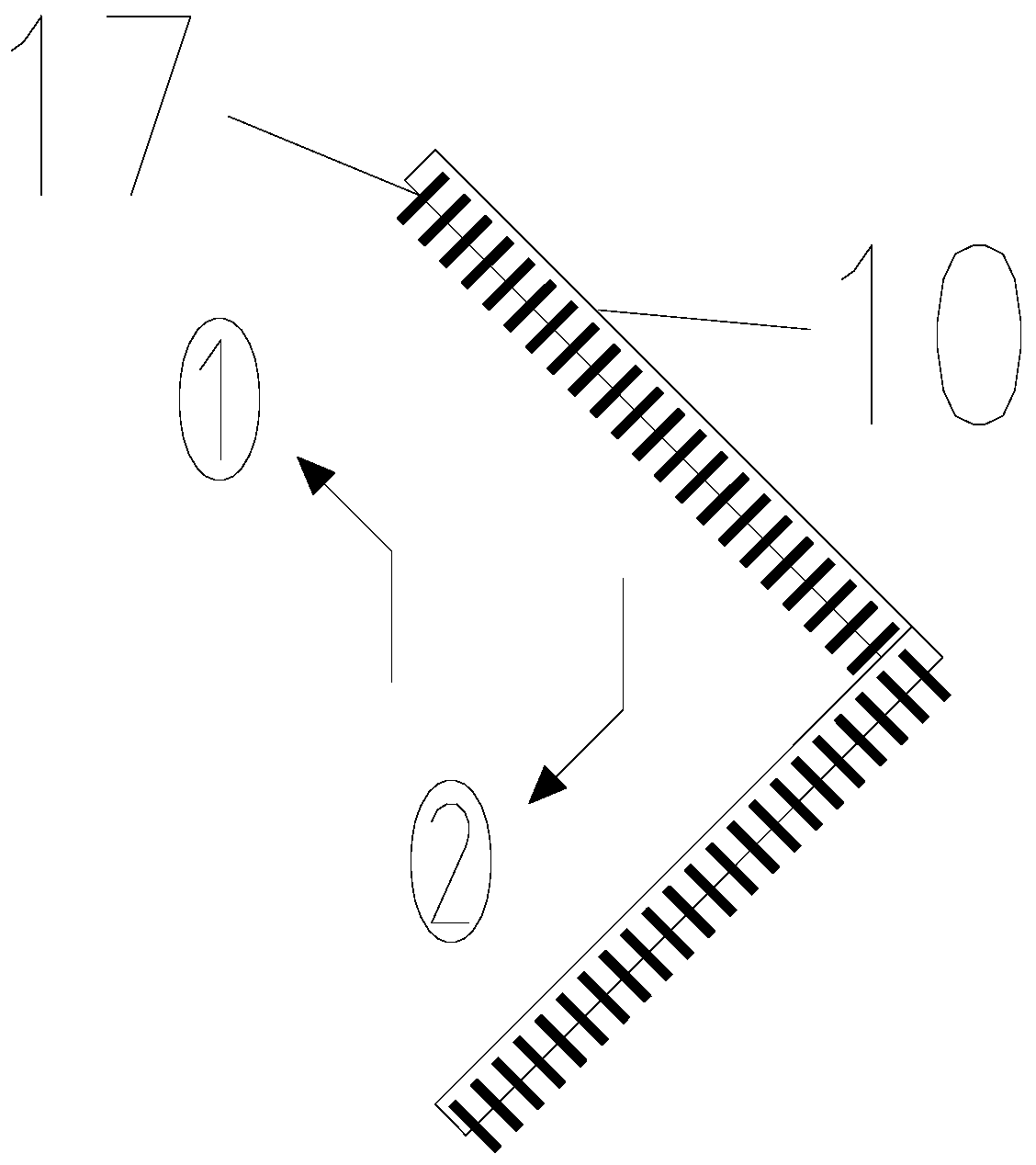

[0063] An enhanced denitrification reactor for deep denitrification, the schematic diagram of its cross-sectional structure is shown in figure 1 , including water inlet pipe 1, air inlet pipe 2, pre-stirring reactor 3, first water distribution pipe 7-1, second water distribution pipe 7-2, third water distribution pipe 7-3, reactor shell 8, first water distribution pipe System 9-1, second water inlet and distribution system 9-2, third water inlet and distribution system 9-3, multi-stage baffle hanging material board, first water retaining plate 11-1, second water retaining plate 11-2 , the third water retaining plate 11-3, overflow plate 12, exhaust valve 13, outlet pipe 14, sludge bucket 15, mud discharge valve 16 and fiber filler 17;

[0064] in,

[0065] The pre-stirred reactor 3 includes a pre-stirred reaction shell, a stirred flow device 5 and a motor 4, the water inlet pipe 1 is connected to the pre-stirred reactor shell, and the described air inlet pipe 2 is connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com