System and technology for trapping CO2 in smoke

A carbon dioxide and process technology, applied in the field of absorption-desorption CO2 capture system, can solve the problems of high regeneration energy consumption and low thermoelectric efficiency, and achieve the effect of reducing heat load, increasing load and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

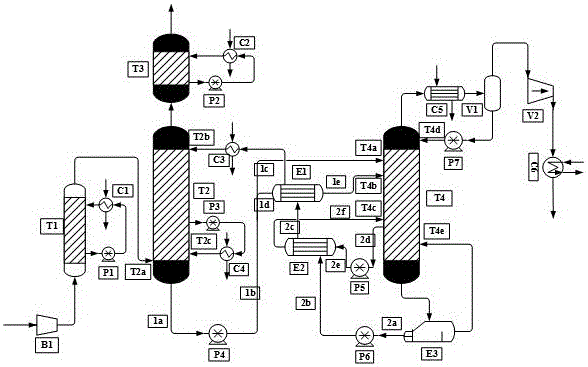

Image

Examples

Embodiment Construction

[0012] In order to better illustrate the feasibility of the present invention and the adopted technical solutions to achieve the intended purpose of the invention, the process and specific implementation methods proposed by the present invention will be described in detail in conjunction with the accompanying drawings. It should be declared that the following examples of implementation are illustrative rather than limiting, and the protection scope of the present invention cannot be limited by the following examples of implementation.

[0013] In the field of application of the process of the present invention (flue gas in power plants and chemical industry), the conditions for setting the feed gas after pretreatment are: pressure 0.11 MPa, temperature 40 °C, volume percentage composition H 2 O 10%, CO 2 12.0%, N 2 78%, the mass flow rate is 3100 t / h, and the flue gas scale is 650 MW power plant (net thermoelectric efficiency is 38.9%) outlet flue gas. Establish the flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com