Disc milling cutter adopting flatly staggered teeth and variable cutting width and applied to slotting rough machining of blisk channel

An integral blisk and runner technology, applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of fixed cutting width, easy tool wear, low processing efficiency, etc., to achieve easy accuracy, convenient replacement process, and tool life. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

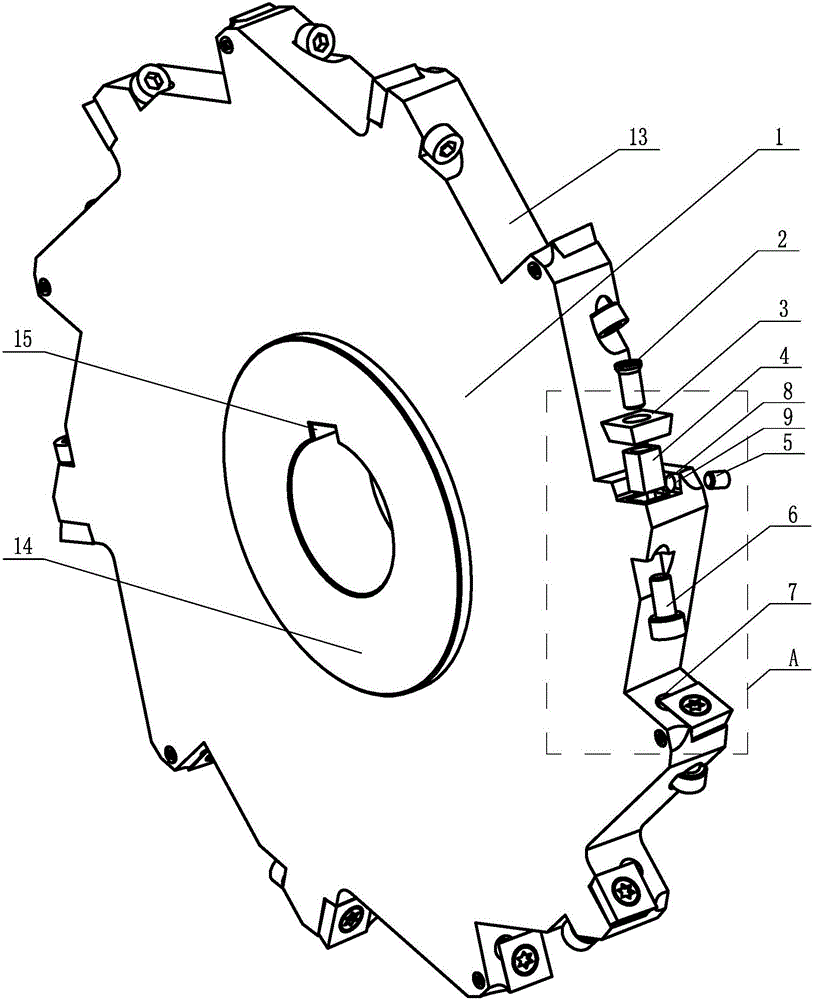

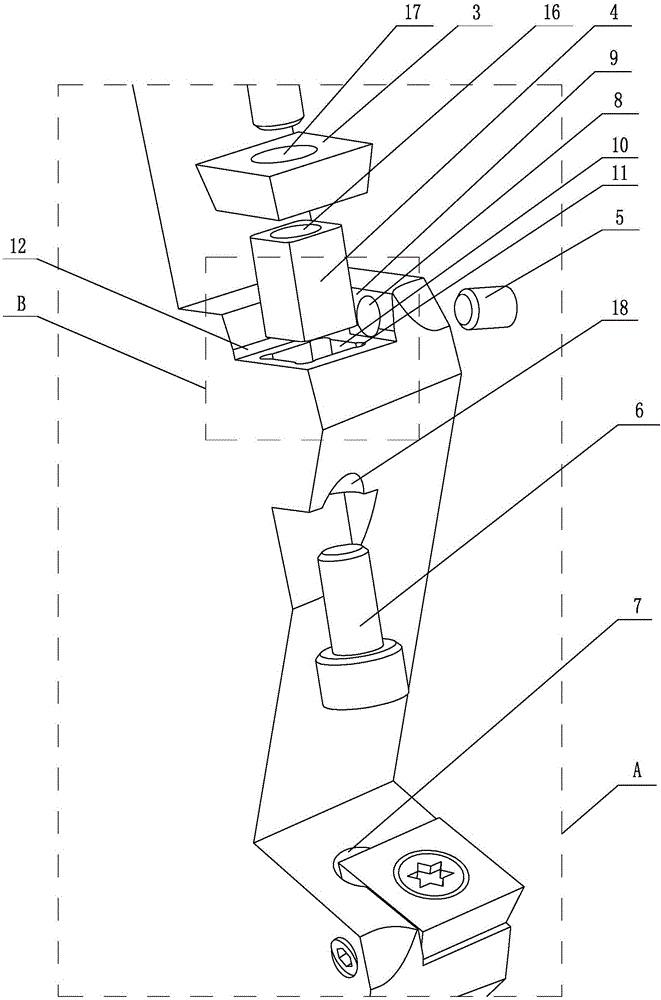

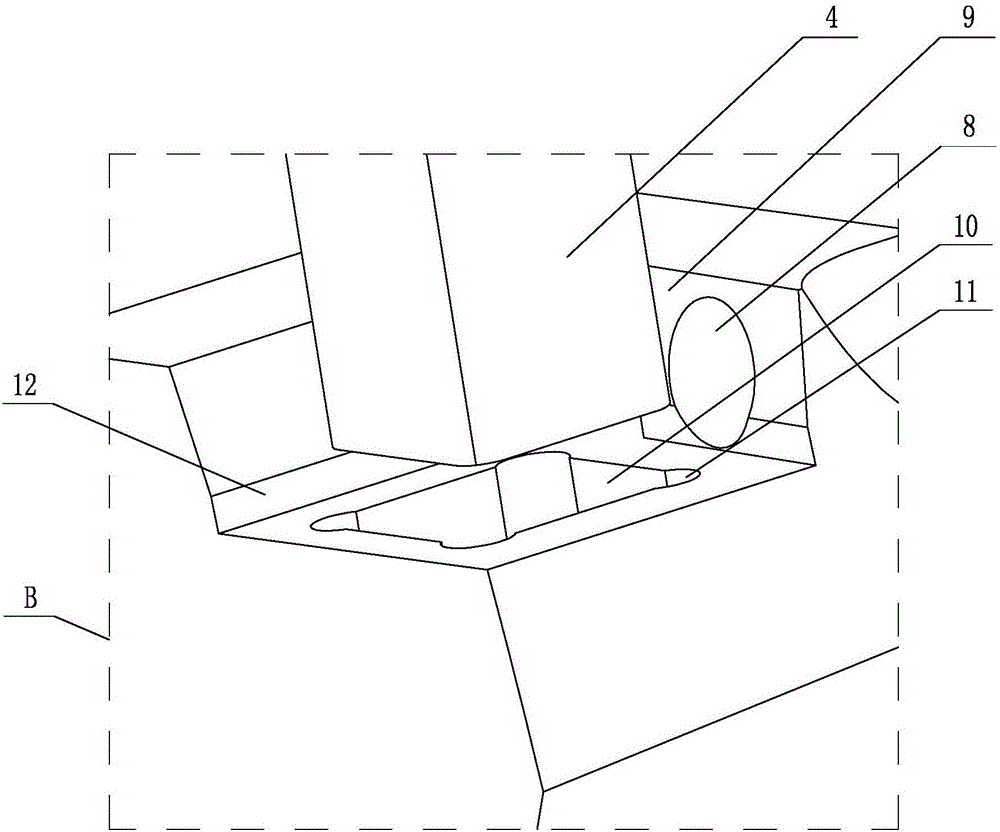

[0021] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, the overall blisk flow channel is thick and flat-mounted with staggered teeth and variable-cut wide disc milling cutter, and its composition includes a cutter body 1, a central bush 14, a plurality of positioning screws 2 and a plurality of blades 3 (the number of blades 3 is preferably 12), the center of the cutter body 1 is processed with a central through hole, the central bushing 14 is fixedly installed in the central through hole of the cutter body 1, and the inner wall of the central bushing 14 is processed with a keyway 15 along the axial direction, The outer circumferential surface of the cutter body 1 is uniformly processed with a plurality of L-shaped chip removal grooves 13, and the plurality of L-shaped chip removal grooves 13 are all set through the thickness of the cutter body 1, and each L-shaped chip removal groove 13 A sipe 9 is processed on the side of the short groove (preferably the ...

specific Embodiment approach 2

[0026] Specific implementation mode two: as Figure 1 ~ Figure 3 As shown in the specific embodiment 1, in the overall blisk flow channel described in the first embodiment, the disc milling cutter with the wrong teeth and variable cutting width is designed, and each of the sipes 9 is designed with a pre-installation angle: that is, the axial rake angle is 4 °~6°, the radial rake angle is 6°~8°, the axial relief angle is 13°~15°, and the radial relief angle is 10°~12°.

specific Embodiment approach 3

[0027] Specific implementation mode three: as figure 1 and figure 2 As shown in the specific embodiment 1, the overall blisk flow channel is thick and flat-mounted with staggered teeth and variable cutting width. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com