Metal plate to be connected with plastic, manufacturing method and metal strip

A production method and technology of metal strips, applied in the direction of metal layered products, metal processing equipment, chemical instruments and methods, etc., can solve the problems of insufficient joint strength, small hole diameter, and inability to embed, so as to maintain strength and integrity , light weight, increase the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

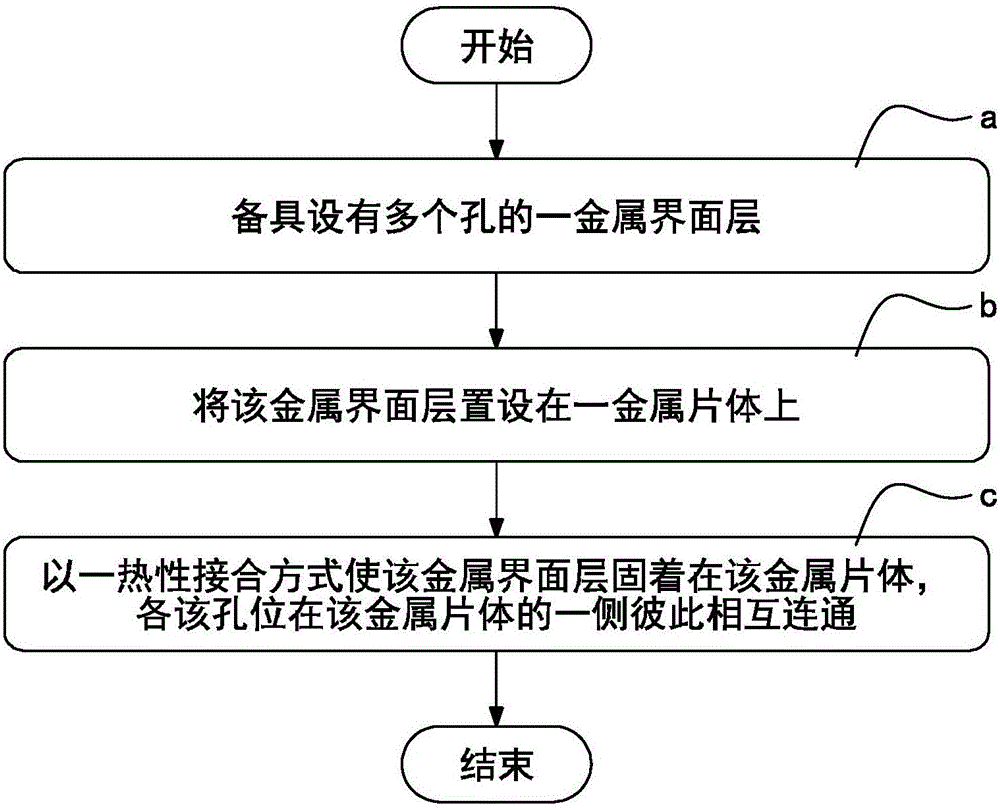

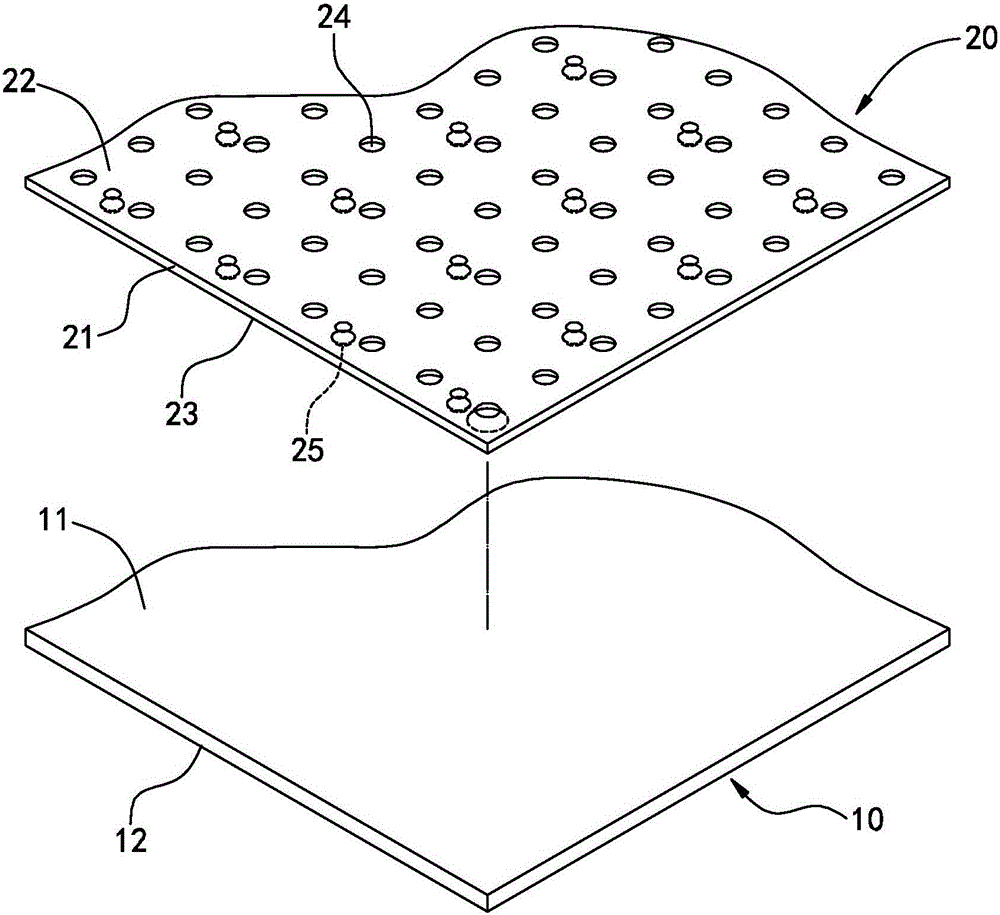

[0056] see figure 1 and Figure 5 As shown, the present invention provides a metal plate for plastic bonding, a manufacturing method and a metal strip, wherein the method steps include:

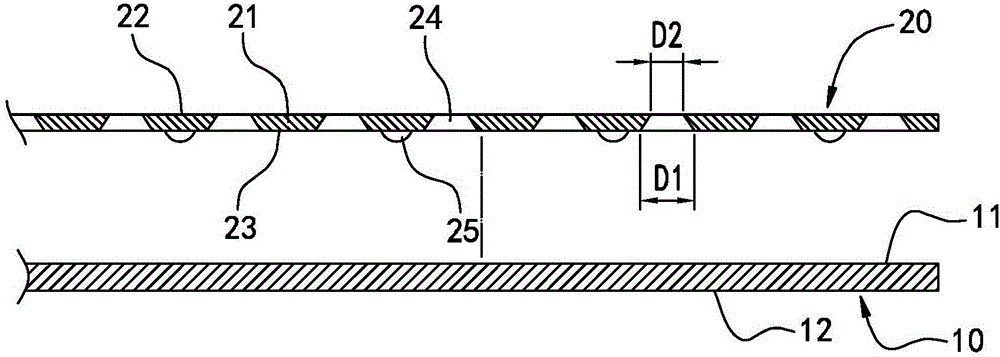

[0057] a) have a metal interface layer 20 with a plurality of perforations 24; see figure 2 and image 3 As shown, the metal interface layer 20 can be light metal materials such as aluminum alloy, magnesium alloy or aluminum-magnesium alloy. The metal interface layer 20 in this embodiment is a thin plate with a thickness between 0.05-0.2 millimeters (mm). Between, wherein the thickness is preferably 0.1 millimeter (mm), the metal interface layer 20 has a sheet 21, the upper side of the sheet 21 is formed with an upper surface 22, the lower side of the sheet 21 is formed at a position facing away from the upper surface 22 There is a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com