A tire steel wire automatic welding and heat treatment machine for preparing high-performance steel shot

A high-performance, tire technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of poor uniformity and consistency, high shot blasting cost, poor geometry, etc., to achieve high production efficiency, easy replacement, elimination effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

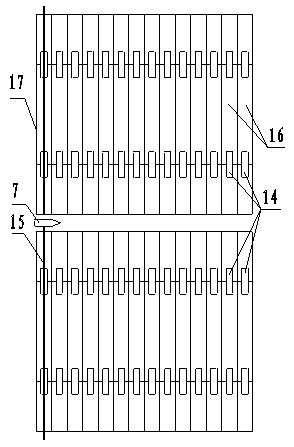

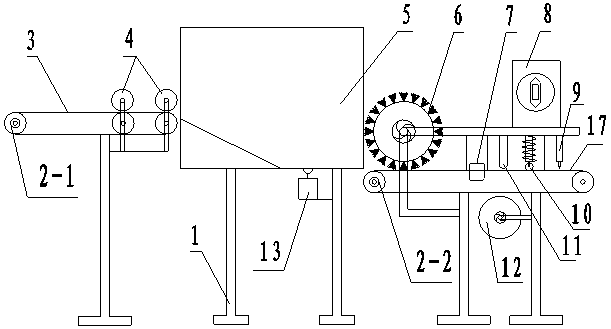

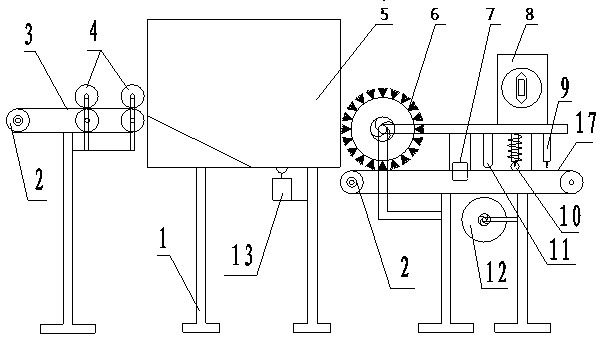

[0017] in such as Figure 1~2 In the shown embodiment, a tire steel wire automatic welding and heat treatment machine for preparing high-performance steel shot consists of a frame 1, a drum motor 2, a conveyor belt 3, a squeeze roller 4, a cloth distributor 5, a cloth brush 6, an initial The positioning mechanism 7, the chain material plate 17, the position sensor 11, the contact mechanism 10, the heat treatment machine 9 and the control system are composed. During work, the tire steel wire 15 will be placed on the conveyor belt 3 by the electromagnetic absorber. The working efficiency determines the adsorption capacity. The drum motor 2 is set on the frame 1, and the conveyor belt 3 is wound on the outer circular surface of the drum motor 2. The drum motor 2 drives the conveyor belt 3 to rotate, and the tire wire 15 follows the conveyor belt 3. , a plurality of extrusion rollers 4 are fixed on the frame 1, the extrusion rollers 4 appear in pairs, the conveyor belt 3 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com