Injection molding method for commercial vehicle sun shade

An injection molding and sunshade technology, which is applied in the field of commercial vehicle sunshade product molding technology, can solve the problem of high shear rate, and achieve the effect of ensuring the appearance effect and reducing the shear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

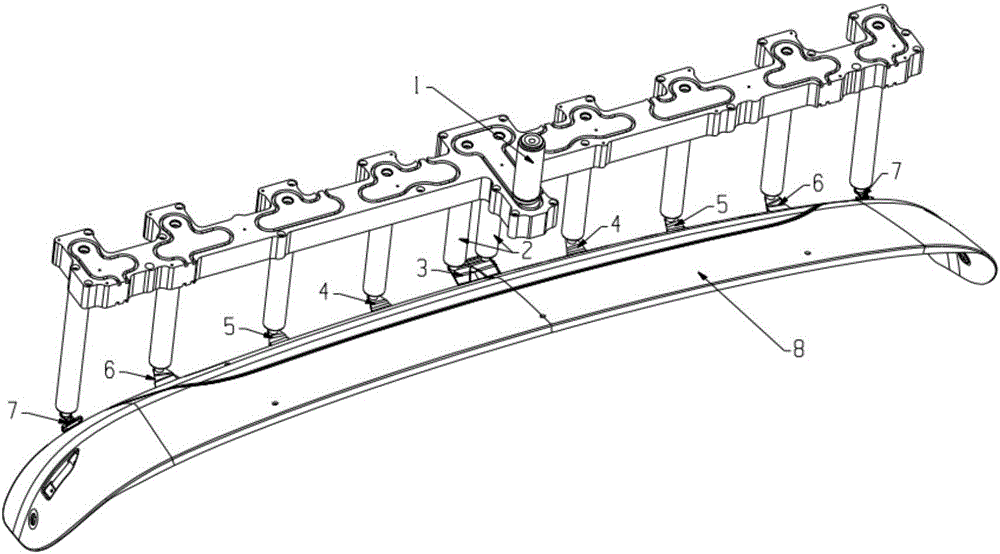

[0015] See figure 1 and figure 2 , an injection molding method for a commercial vehicle sunshade, specifically comprising the steps of:

[0016] 1) The molten plastic passes through the main nozzle 1 of the intermediate hot runner, passes through the two-point hot runner 2 and then passes through the gate 3 of the intermediate cold runner, and enters the product cavity 8;

[0017] 2) Then open the second cold runner gate 4, the third cold runner gate 5, the fourth cold runner gate 6, and the fifth cold runner gate symmetrically arranged on both sides of the middle cold runner gate in order Gate 7, injecting plastic into the product cavity;

[0018] 3) Keep the injection pressure of each gate until the product cavity is fully filled.

[0019] In the above step 1), the inner valve needle and melt cavity of the two-point hot runner 2 are enlarged and polished.

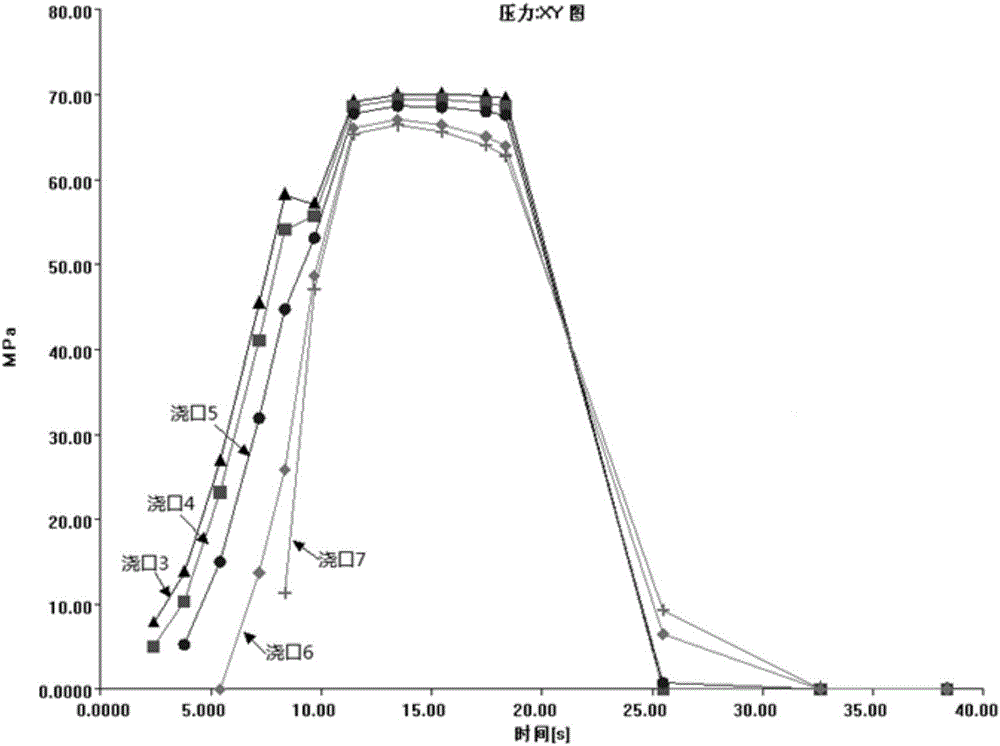

[0020] The pressure-time curves of the above-mentioned cold runner gates are parabolic, the highest pressure range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com