Device and method for absorbing free sulfur trioxide in fuming sulfuric acid through concentrated sulfuric acid

A technology of fuming sulfuric acid and sulfur trioxide, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as adverse effects of equipment and catalysts, smoke from exhaust chimneys, blockage of degassing pipes, etc., to improve comprehensive Utilization rate, high absorption efficiency, effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

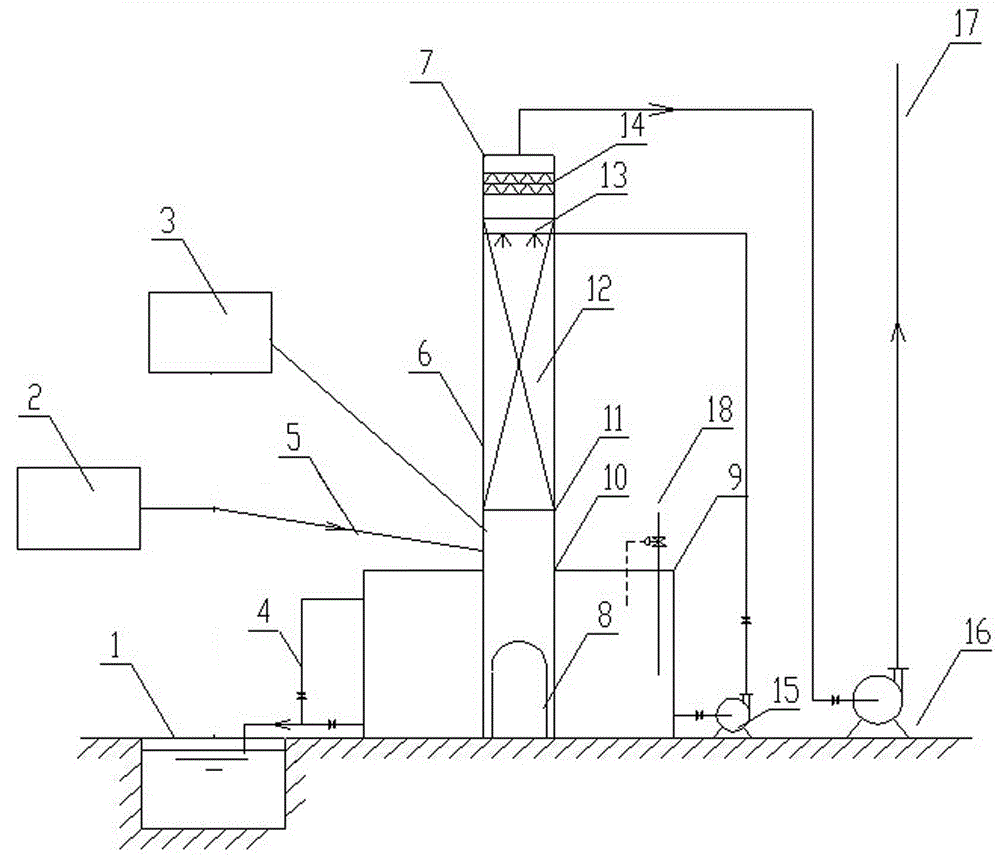

[0023] Inject liquid concentrated sulfuric acid with a concentration of 98.5% from the acid tank truck into the circulation tank 9, check the fuming acid underground tank 1, the acid loading device 2, the 104.5% oleum storage tank 3, the inlet degassing pipe of the absorption tower 5, Pipelines and valves such as exhaust fan 16 and low-altitude discharge pipe 17 ensure that the gas path is unimpeded. 104.5% oleum storage tank 3, acid installation 2, and free SO escaping from underground tank 1 3 It enters from the lower part of the absorption tower. When the liquid level of the circulation tank 9 reaches 1m, start the absorption tower circulating acid pump 15, and the flow rate of the circulating acid pump 15 is about 8m 3 / h, the concentrated sulfuric acid is transported to the acid separation device 13 at the top of the absorption tower, and is evenly distributed from the top of the tower through the packing layer 12, and the free SO from bottom to top 3 Full contact and a...

Embodiment 2

[0025] Inject liquid concentrated sulfuric acid with a concentration of 98% from the acid loading tank truck into the circulation tank 9, and check the fuming acid underground tank 1, acid loading device 2, fuming sulfuric acid storage tank 3, absorption tower inlet degassing pipe 5, and exhaust fan in advance 16. Low-altitude discharge pipe 17 and other pipelines and valves ensure the smooth flow of the gas path. 104.5% oleum storage tank 3, acid installation 2, and free SO escaping from underground tank 1 3 It enters from the lower part of the absorption tower. When the circulation tank liquid level reaches 1m, start the absorption tower circulation acid pump 15, and the flow rate of the circulation acid pump is about 8m 3 / h, the concentrated sulfuric acid is transported to the acid separation device 13 at the top of the absorption tower, and is evenly distributed from the top of the tower through the packing layer 12, and the free SO from bottom to top 3 After the gas is...

Embodiment 3

[0027]Inject liquid concentrated sulfuric acid with a concentration of 93% from the acid loading tank truck into the circulation tank 9, and check the fuming acid underground tank 1, acid loading device 2, fuming sulfuric acid storage tank 3, absorption tower inlet degassing pipe 5, and exhaust fan in advance 16. Low-altitude discharge pipe 17 and other pipelines and valves ensure the smooth flow of the gas path. 104.5% oleum storage tank 3, acid installation 2, and free SO escaping from underground tank 1 3 It enters from the lower part of the absorption tower. When the circulation tank liquid level reaches 1m, start the absorption tower circulation acid pump 15, and the flow rate of the circulation acid pump is about 6m 3 / h, the concentrated sulfuric acid is transported to the acid separation device 13 at the top of the absorption tower, and is evenly distributed from the top of the tower through the packing layer 12, and the free SO from bottom to top 3 After the gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com