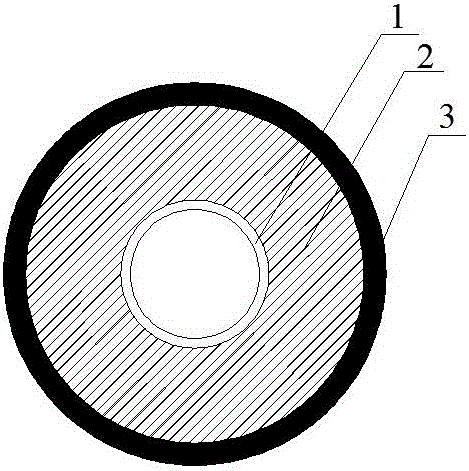

High-density rigid polyurethane foam material prefabricated heat insulating pipeline and prefabricating method

A technology of polyurethane rigid foam and thermal insulation pipeline, which is applied in the direction of thermal insulation protection of pipelines, thermal insulation, pipeline protection, etc., can solve the problems of insufficient pressure bearing capacity and poor high temperature resistance performance of thermal insulation pipelines, and achieves good thermal insulation effect and long service life. , The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

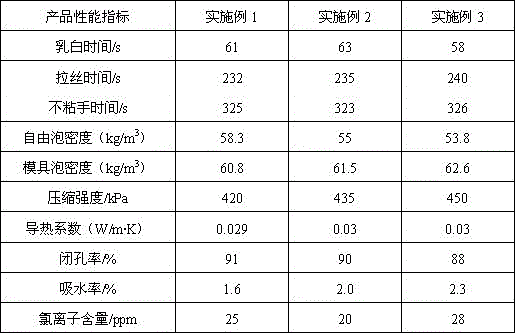

Embodiment 1

[0034] A prefabricated thermal insulation pipe, which is prepared by the following steps:

[0035] a) Preparation of prefabricated pipe cavity mold: nest and fix the working pipe in the outer protective pipe, seal the two ports of the working pipe and the outer protective pipe with flanges, adjust the ends and flanges, and control the length of the remaining head according to the design requirements.

[0036] b) Preparation of white material: Weigh 60kg combined polyether polyol DC380, 30kg polyether polyol DC635C, 10kg polyether polyol N210 (total 100kg combined polyether polyol, equivalent to 100 parts by weight), 2kg silicone oil SD624 ( Suzhou Side New Material Technology Co., Ltd.), 0.4kg dimethylcyclohexylamine catalyst PC-8 (Air Chemical Co., Ltd.), 1.6kg dimethylaniline catalyst DABCO (Air Chemical Co., Ltd.) (total 2kg catalyst, Equivalent to 2 parts of catalyst), 2kgH 2 O (equivalent to 2 parts of foaming agent) is put into the mixing kettle and stirred for 40 minutes unt...

Embodiment 2

[0044] A prefabricated thermal insulation pipe, which is prepared by the following steps:

[0045] a) Preparation of prefabricated pipe cavity mold: nest and fix the working pipe in the outer protective pipe, seal the two ports of the working pipe and the outer protective pipe with flanges, adjust the ends and flanges, and control the length of the remaining head according to the design requirements.

[0046] b) Preparation of white material: respectively weigh 50kg combined polyether polyol DC380, 40kg polyether polyol DC635C, 10kg polyether polyol N210, 2.3kg silicone oil AK8805, 0.3kg dimethylcyclohexylamine catalyst PC-8, 1.5kg dimethylaniline catalyst BDMA (Dajiang Chemical Co., Ltd.), 1.2kg triazine catalyst PC-41 (Air Chemical Co., Ltd.), 3kgH 2 Put O into the mixing kettle and stir for 50 minutes until the mixture is uniform.

[0047] c) Preparation of high-density polyurethane rigid foam: Calculate the volume of the cavity mold between the prefabricated pipeline working stee...

Embodiment 3

[0049] A prefabricated thermal insulation pipe, which is prepared by the following steps:

[0050] a) Preparation of prefabricated pipe cavity mold: nest and fix the working pipe in the outer protective pipe, seal the two ports of the working pipe and the outer protective pipe with flanges, adjust the ends and flanges, and control the length of the remaining head according to the design requirements.

[0051] b) Preparation of white material: respectively weigh 55kg combined polyether polyol NJ4502, 40kg polyether polyol GB4110A, 5kg polyether polyol N210, 3kg silicone oil B8525 (Gosmeet), 0.6kg dimethylcyclohexylamine Catalyst PC-8 (Air Chemical Co., Ltd.), 0.4kg dimethylaniline catalyst DABCO, 1kgH 2 Put O into the mixing kettle and stir for 60 minutes until the mixture is uniform.

[0052] c) Preparation of high-density polyurethane rigid foam: Calculate the volume of the cavity mold between the prefabricated pipe working steel pipe and the outer protective pipe, and press 85kg / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com