Package of polycarbonate diol, saving method, and transporting method

A polycarbonate diol, packaging technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as the reduction of commodity value, and achieve the effect of inhibiting the intensification of coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

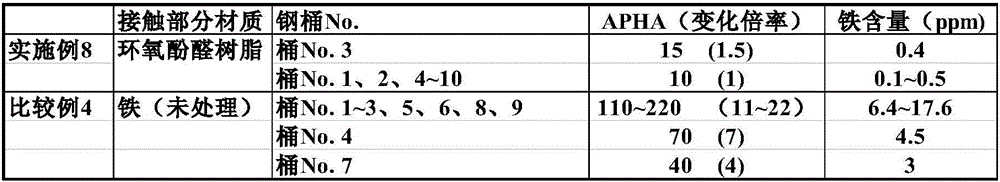

[0163] (storage test)

[0164] As packing containers for packing polycarbonate diol, 10 steel drums (manufactured by JFE CONTAINER CO., LTD.) (No. 1 to No. 10) were prepared. A layer of iron phosphate was formed on the portion of the packaging container that was in contact with the polycarbonate diol. 200 kg of polycarbonate diol (product name: T5652, manufactured by Asahi Kasei Chemical Co., Ltd.) was put into this packaging container, and this packaging container was sealed to obtain a package. The obtained packages were stored in an indoor warehouse (room temperature 20±20° C.) for one year. Before this storage, the content of the cyclic carbonate and the cyclic ether in the polycarbonate diol was analyzed by the method described above, and the total amount was 0.3% by mass based on 100% by mass of the polycarbonate diol. The Hazen chroma (APHA) of the polycarbonate diol before storage was 10, and the APHA of the polycarbonate diol after storage in an indoor warehouse (ro...

Embodiment 2

[0166] (storage test)

[0167] As packing containers for packing polycarbonate diol, 10 steel drums (manufactured by JFE CONTAINER CO., LTD.) (No. 1 to No. 10) were prepared. A zinc phosphate layer was formed on the part of the packaging container that was in contact with the polycarbonate diol. 200 kg of polycarbonate diol (product name: T5652, Asahi Kasei Chemical Co., Ltd.) was put into the packaging container, and the packaging container was sealed to obtain a package. The obtained packages were stored in an indoor warehouse (room temperature 20±20° C.) for one year. The Hazen Chromaticity (APHA) of the polycarbonate diol before the above storage is 10, and the maximum APHA of the polycarbonate diol after storage in an indoor warehouse (room temperature 20±20°C) for one year is 1 barrel. , the rest remain unchanged, still 10. The results are shown in Table 1.

Embodiment 3

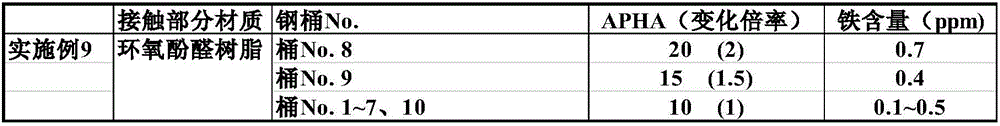

[0174] (storage test)

[0175] A storage test was performed in the same manner as in Example 1, except that it was stored in a heating room at 60° C. for 3 months instead of storage in an indoor warehouse. The maximum value of APHA of the polycarbonate diol after this storage test was 30. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com