Membrane antistatic fluid and method for preparing antistatic membrane from same

An antistatic liquid and thin film technology, which is applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as large thin films, hidden dangers in product quality, burnout or breakdown of electronic components, and achieve dirt removal , reduce the amount of static electricity, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

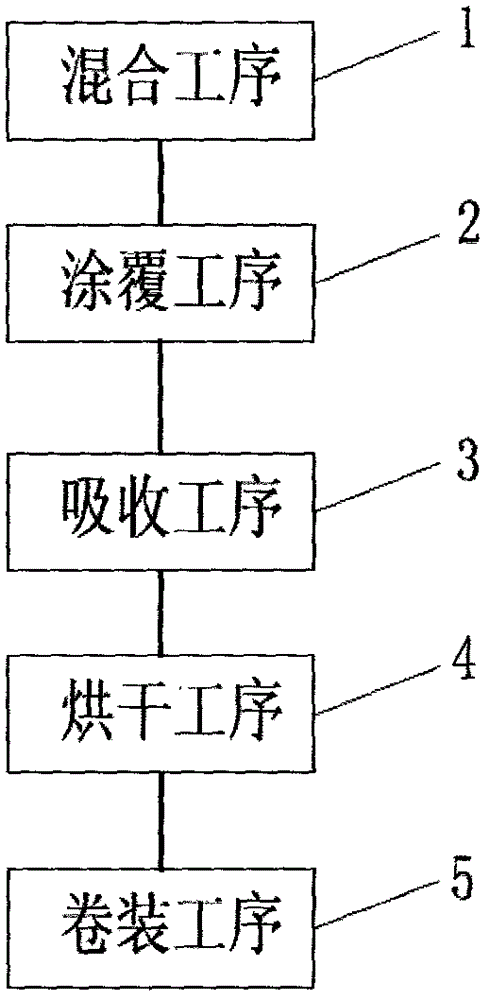

[0039] Embodiment 1: Make 100ml of film antistatic liquid, including: ethanol 60ml, conductive liquid 1.6ml, white electric oil 8.3ml, essence 0.1ml, water 30ml. The antistatic film is prepared through the following steps: mixing process 1, placing ethanol, conductive liquid, white electric oil, essence, and water in the container according to the weight percentage ratio, stirring and mixing evenly at room temperature, wherein the You can use lemon essence first, and then put the uniformly mixed anti-static liquid to stand for a period of time; coating process 2, pour the anti-static liquid mixed in mixing process 1 into the coating machine, start the coating machine, and put the anti-static liquid into the coating machine. The liquid is evenly coated on the surface of the expanded polytetrafluoroethylene film; in the absorption process 3, the expanded polytetrafluoroethylene film coated in the coating process 2 is placed at room temperature, so that the antistatic liquid is ev...

Embodiment 2

[0040] Embodiment 2: Make 100ml of film antistatic liquid, including: ethanol 65ml, conductive liquid 2.5ml, white electric oil 14ml, essence 0.15ml, water 18.35ml. The essence described therein can use lemon essence earlier. The antistatic film of this embodiment is prepared by the method of the above-mentioned embodiment 1, wherein the temperature in the normal temperature state of the mixing step 1 is 25° C., the stirring time is 10 minutes, and the standing time is 30 minutes. The temperature of the normal temperature state in the absorption process 3 is 25°C, and the surface resistance value of the expanded polytetrafluoroethylene film after absorbing the antistatic liquid is 10 7 ohm. The heating temperature in the drying step 4 is 80° C., and the heating and drying time is 5 minutes. The antistatic film produced by the formula of this embodiment and its preparation process is used to wrap the drag chain of mechanical equipment. The antistatic film can effectively redu...

Embodiment 3

[0041] Embodiment 3: Make 100ml of film antistatic liquid, including: ethanol 70ml, conductive liquid 5ml, white electric oil 7.8ml, essence 0.2ml, water 17ml. The essence described therein can use lemon essence earlier. The antistatic film of this example is prepared by the method of Example 1, wherein the temperature of the mixing step 1 at room temperature is 20° C., the stirring time is 8 minutes, and the standing time is 27 minutes. The temperature in the normal temperature state of the absorption process 3 is 20°C, and the surface resistance value of the expanded polytetrafluoroethylene film after absorbing the antistatic liquid is 10 6 ohm. The heating temperature in the drying step 4 is 70° C., and the heating and drying time is 6 minutes. The antistatic film produced by the formula of this embodiment and its preparation process is used to wrap the drag chain of mechanical equipment. The antistatic film can effectively reduce the amount of static electricity generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com