Secondary weighing method of aggregate based on key screen

A secondary metering and material metering technology, which is applied in roads, buildings, road repairs, etc., can solve problems such as the process and system that do not guarantee the accuracy of key material ratios, and achieve the effects of reducing road surface diseases, ensuring grading accuracy, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

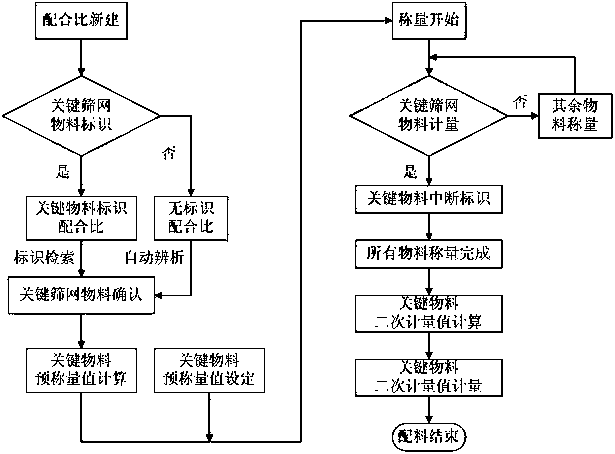

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

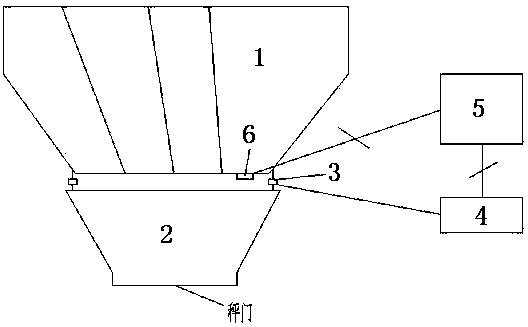

[0023] The aggregate secondary weighing system based on the key screen of the present invention includes a material storage bin 1 , a weighing scale hopper 2 , a detection device 3 , a signal processor 4 , a controller 5 and an actuator 6 . The detection device 3 in the metering system detects the weight change of the material in the weighing scale bucket 2 in real time, and converts the weight change of the material into an electrical signal. The signal processor 4 converts the weight change signal output by the detection device 3 into a standard electrical signal and transmits it to the The controller 5, the controller 5 performs arithmetic processing according to the standard elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com