Construction method of sand box combined all-sand base form for supporting the upper wall of the abutment of the 10,000-ton swivel arch bridge

A construction method and technology of sand boxes, which are applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of heavy weight and economic loss, and achieve the effects of no waste of resources, low cost, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

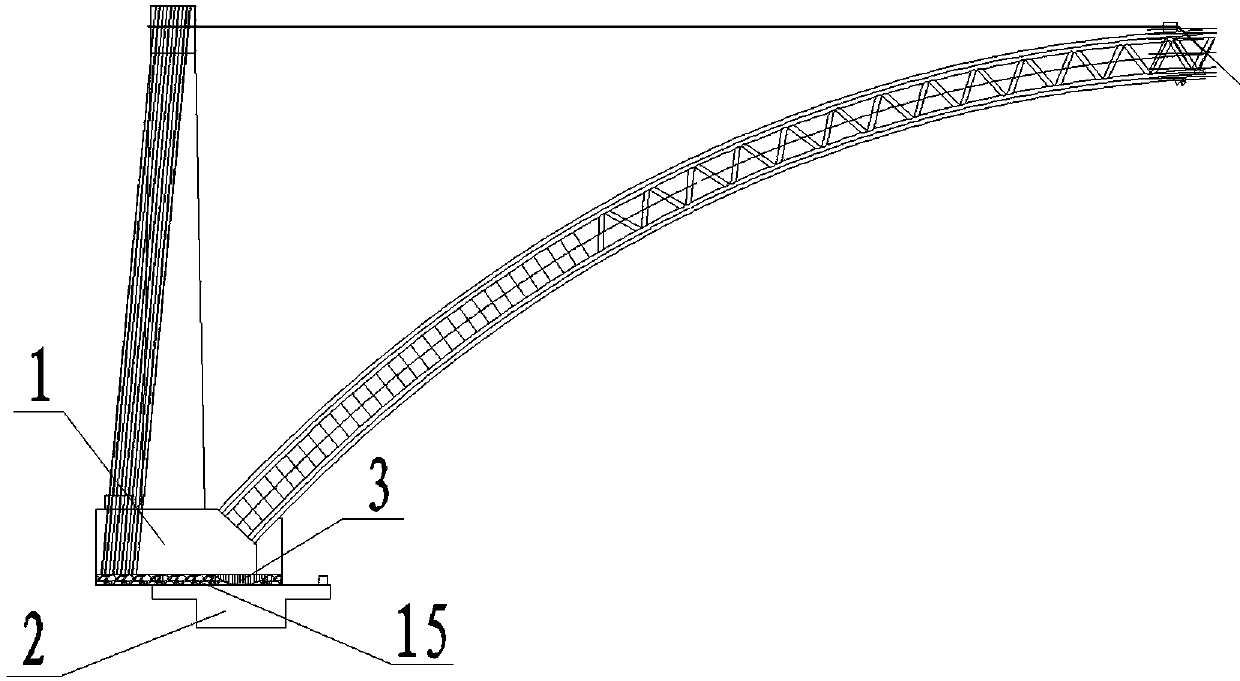

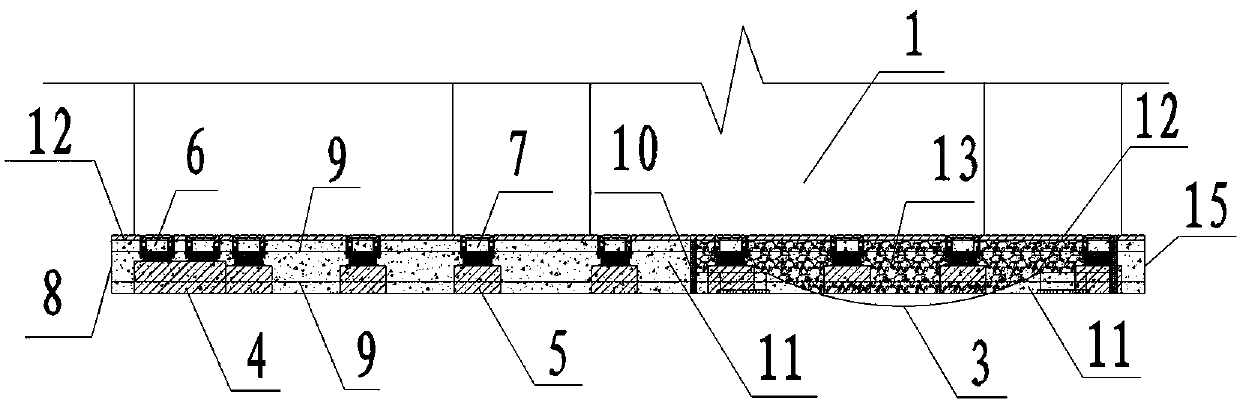

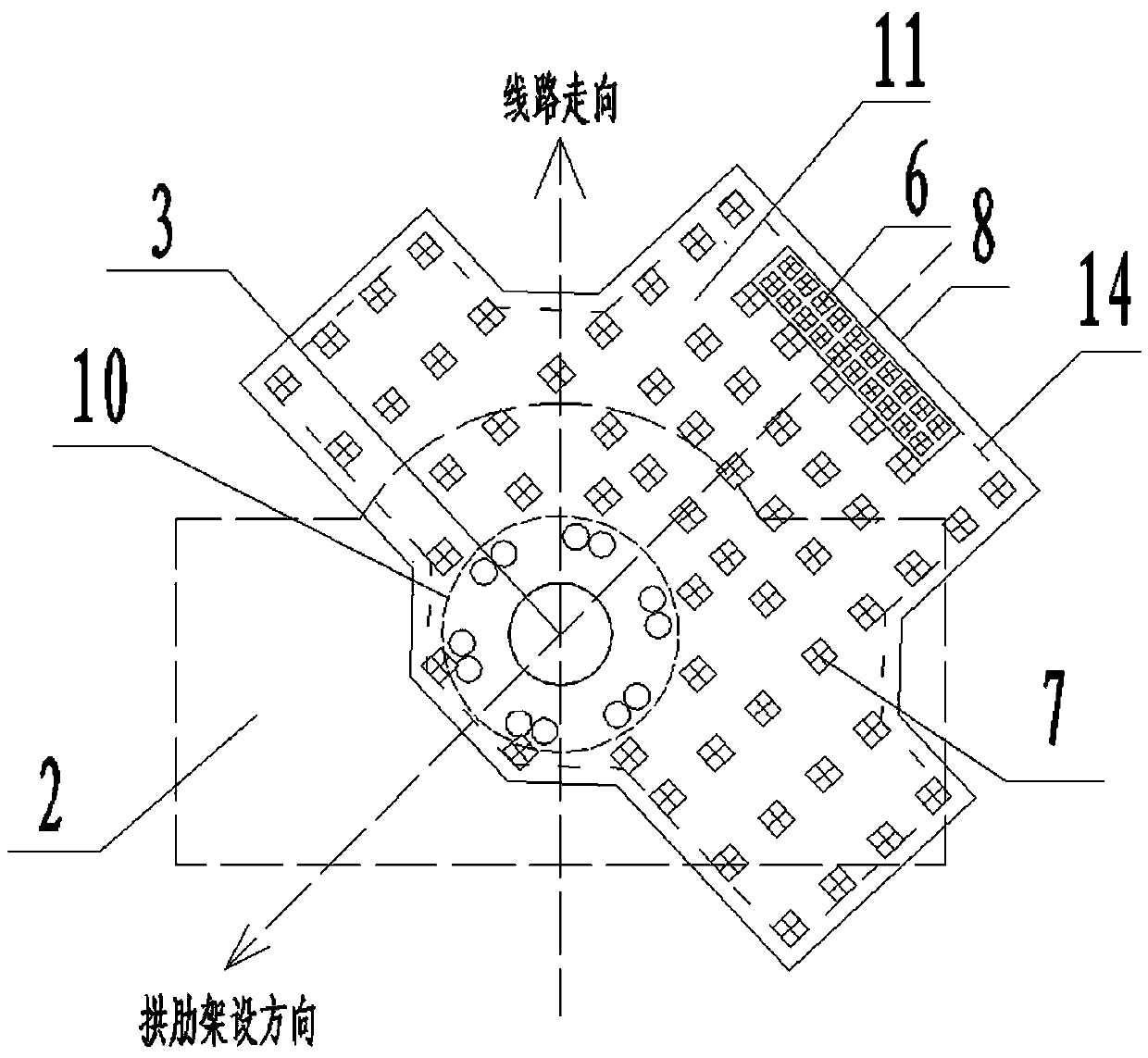

[0029] see figure 1 , figure 2 , image 3 , a method for constructing a sandbox-combined all-sand bottom form for supporting the upper plate of the abutment of a 10,000-ton swivel arch bridge, comprising the following steps:

[0030] Step (1): After the construction of the lower wall 2 of the abutment of the swivel arch bridge is completed, the side formwork 8 is set on the boundary of the pouring contour of the upper wall 1 by 50 cm, and the tie bars 9 are set to reinforce the side formwork 8, surrounded by the side formwork 8 The area forms the layout range of the sand box combination full sand bottom form 15. The formwork is made of steel formwork, and the tie bars 9 for formwork fixing are welded by Φ20 stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com