solid brick filter well

A technology of solid bricks and water wells, applied in the field of environmental engineering, can solve the problems of wasting resources, hindering the fluidity of solid brick water bodies, and being unable to carry out construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

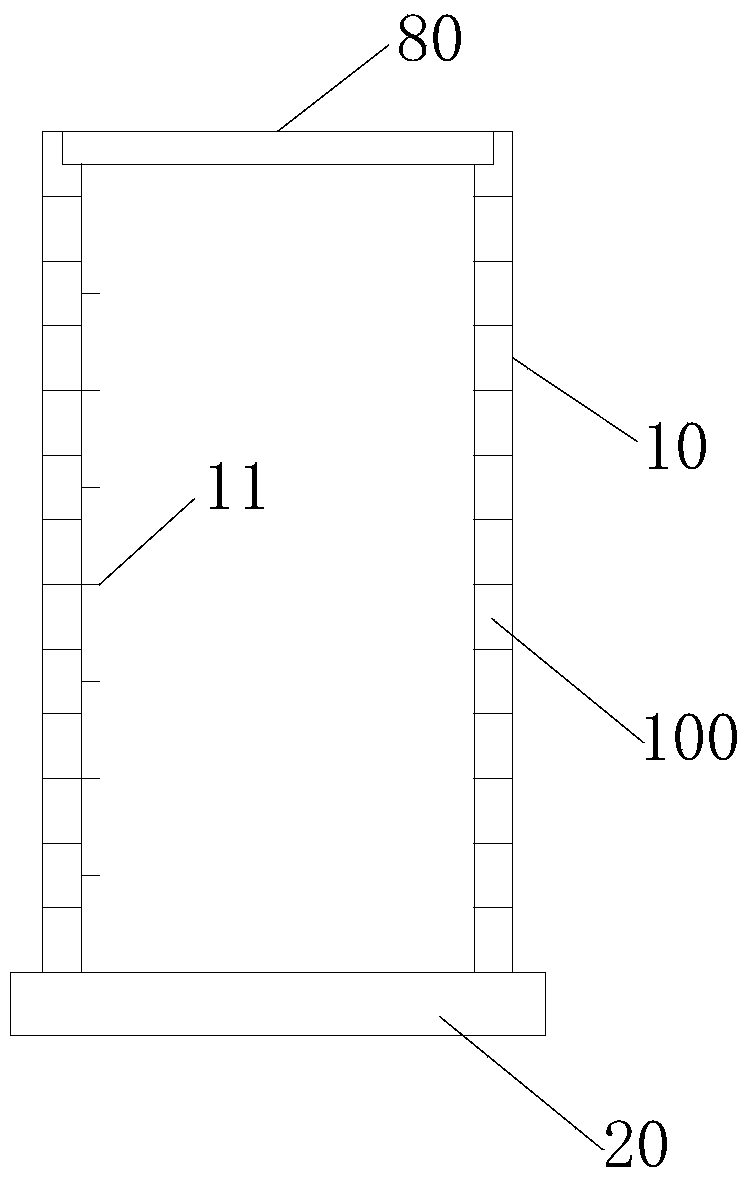

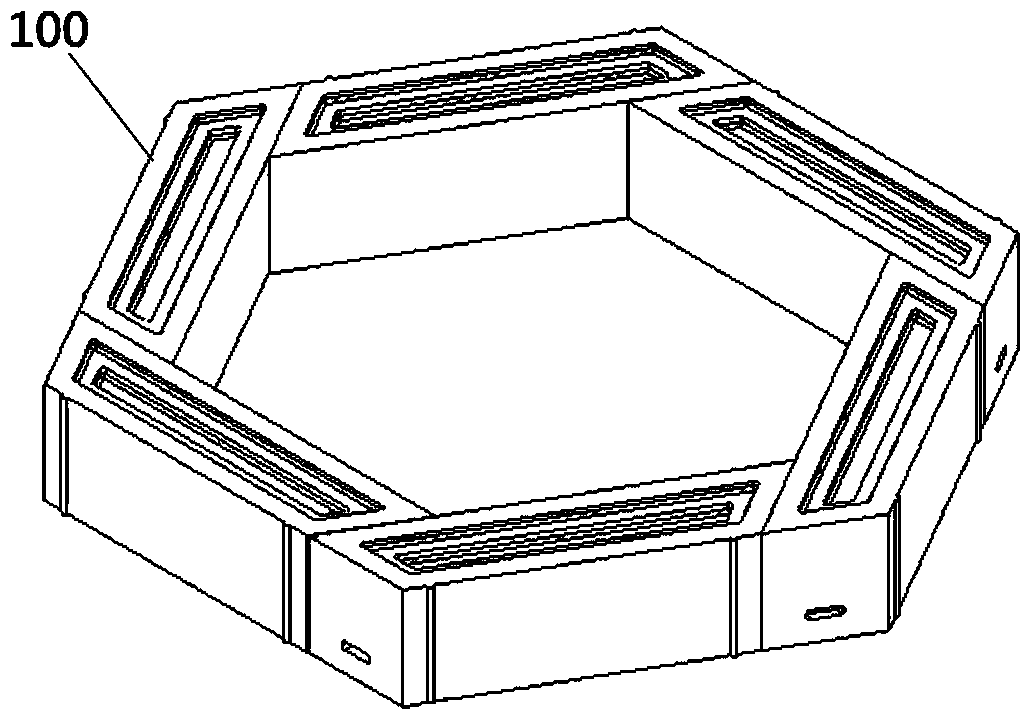

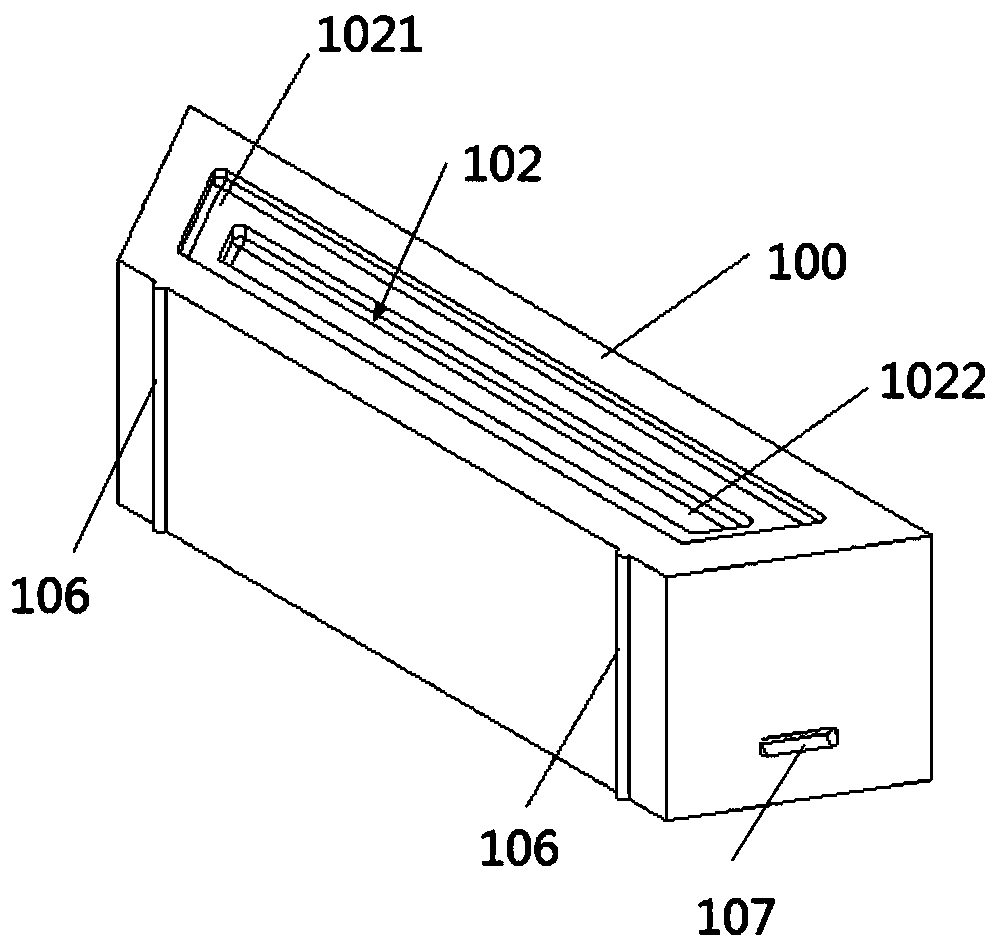

[0031] Such as Figure 1 to Figure 4 As shown, the present invention provides a filter well built with solid bricks, including a well wall 10 and a well bottom 20. The well wall 10 includes multi-layer well bricks stacked up and down, and each layer of well bricks includes a plurality of sequentially spliced bricks. The brick body 100, the top surface of each brick body 100 is provided with a slot part 102, and the bottom surface is provided with a plug-in part 103 matched with the slot part 102, so that there is a gap between two adjacent brick bodies 100 up and down. The socket part 102 and the socket part 103 are inserted into each other.

[0032] In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com